18 Years Factory 5 Axis Cnc Machining - How are These Thin-Walled Parts Produced? – Basile Detail:

How are These Thin-Walled Parts Produced?

Metal spinning is a symmetrical rotational forming process for sheet metal. The spindle drives the blank and the mold core to rotate, and then the rotary wheel applies pressure to the rotating blank. Due to the rotary motion of the main shaft of the spinning machine and the longitudinal and transverse feed motion of the tool, this local plastic deformation gradually expands to the entire blank, thereby obtaining various shapes of hollow rotating body parts.

Process cost: mold cost (low), single piece cost (medium)

Typical products: furniture, lamps, aerospace, transportation, tableware, jewelry, etc.

Yield suitable: small and medium batch production

Surface Quality:

Surface quality is largely dependent on operator skill and production speed

Machining speed: Moderate to high production speed, depending on part size, complexity and sheet metal thickness

Applicable materials:

Suitable for warm metal sheets such as stainless steel, brass, copper, aluminum, titanium, etc.

Design Considerations:

1. Metal spinning is only suitable for the manufacture of rotationally symmetrical parts, and the most ideal shape is hemispherical thin-shell metal parts;

2. For parts formed by metal spinning, the internal diameter should be controlled within 2.5m.

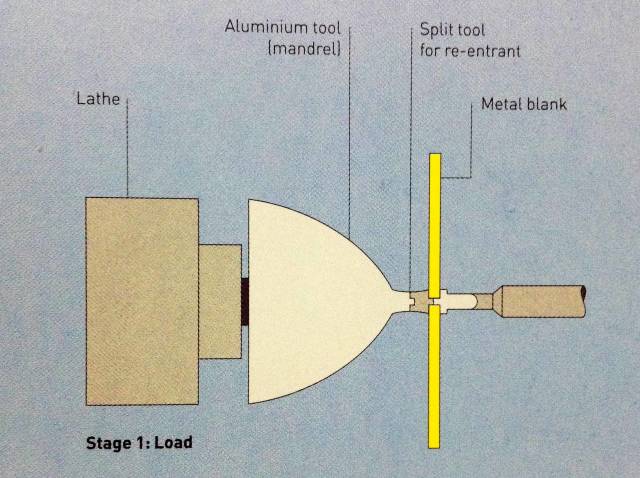

Step 1: Fix the cut round metal sheet on the machine mandrel.

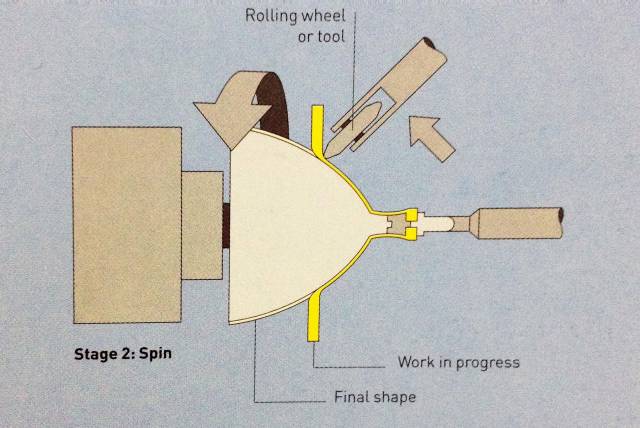

Step 2: The mandrel drives the circular metal plate to rotate at a high speed, and the tool with the runner begins to press the metal surface until the metal plate completely fits the inner wall of the mold.

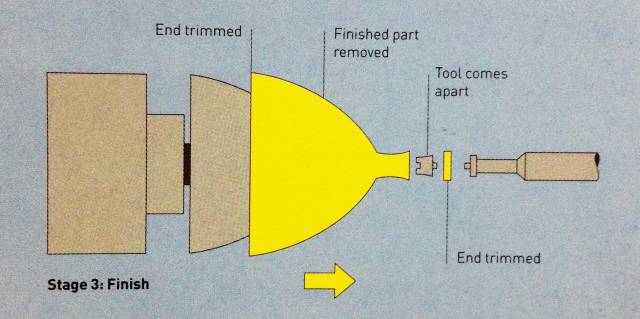

Step 3: After molding is complete, the mandrel is removed and the top and bottom of the part are cut off for demolding.

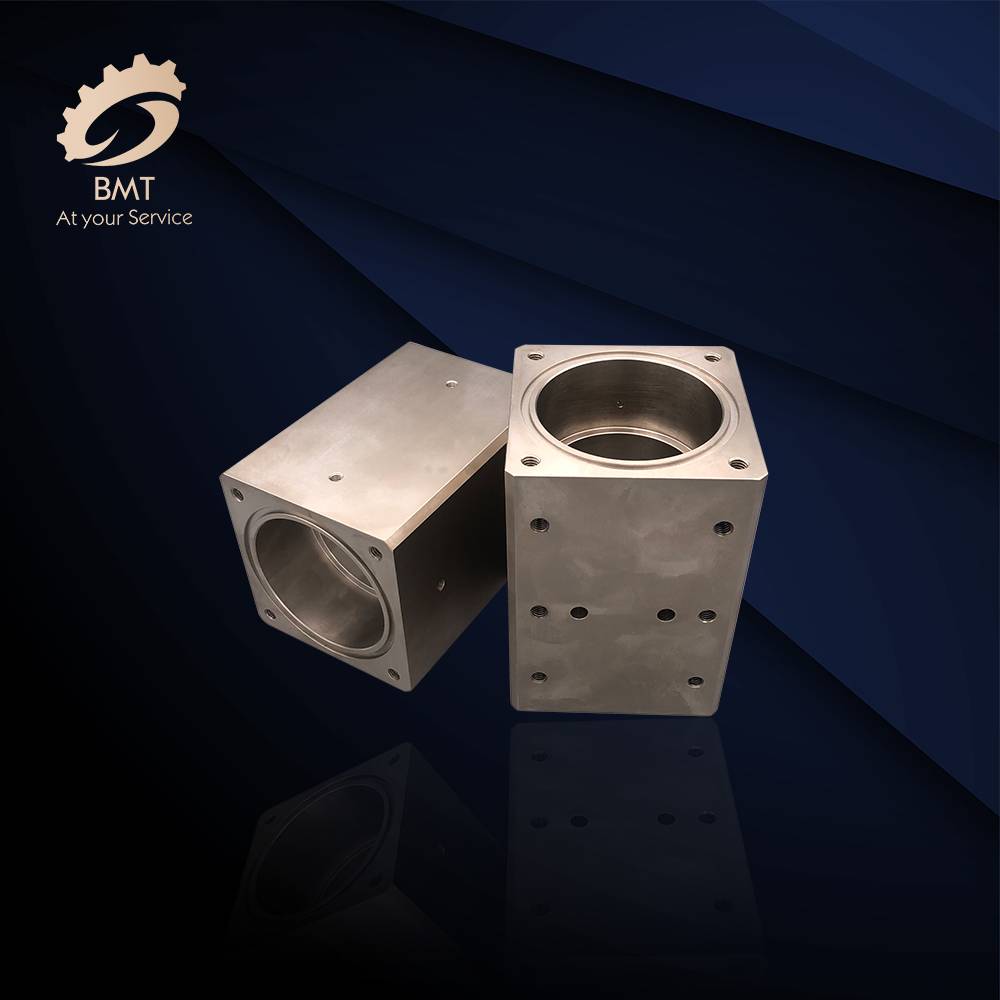

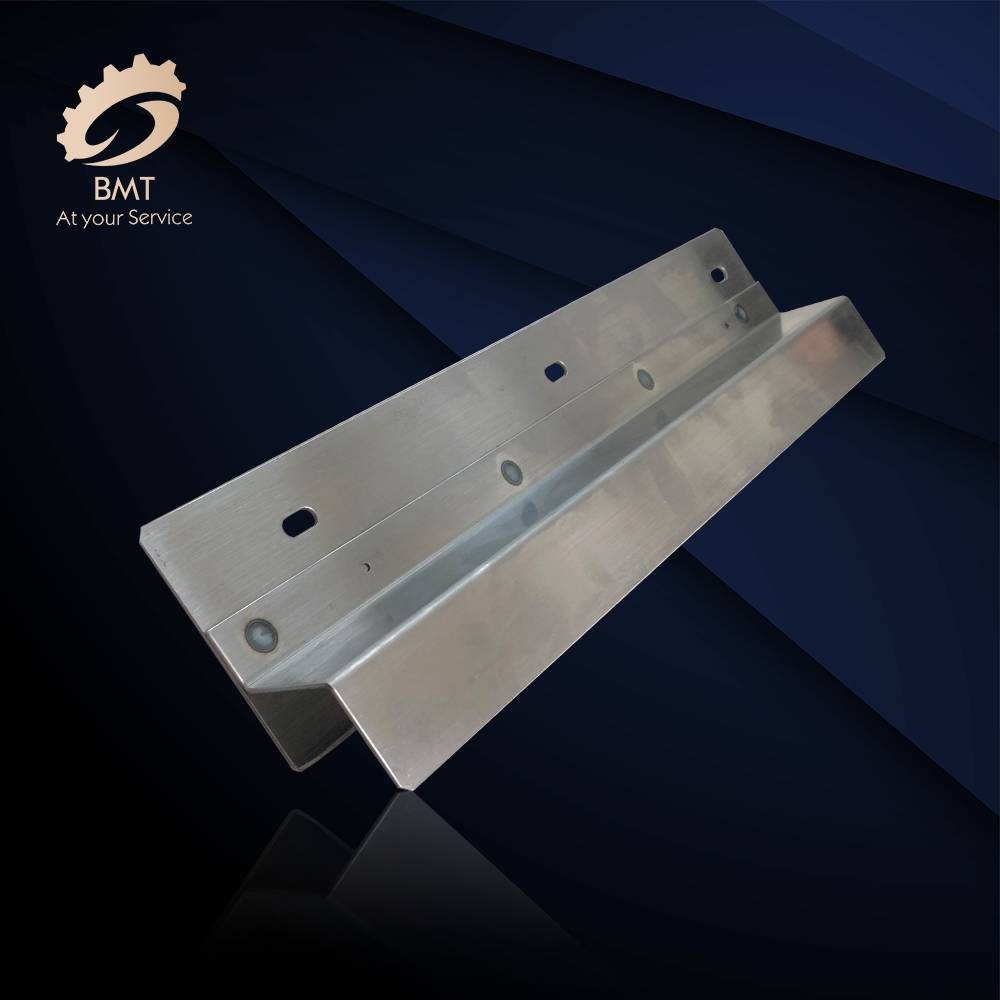

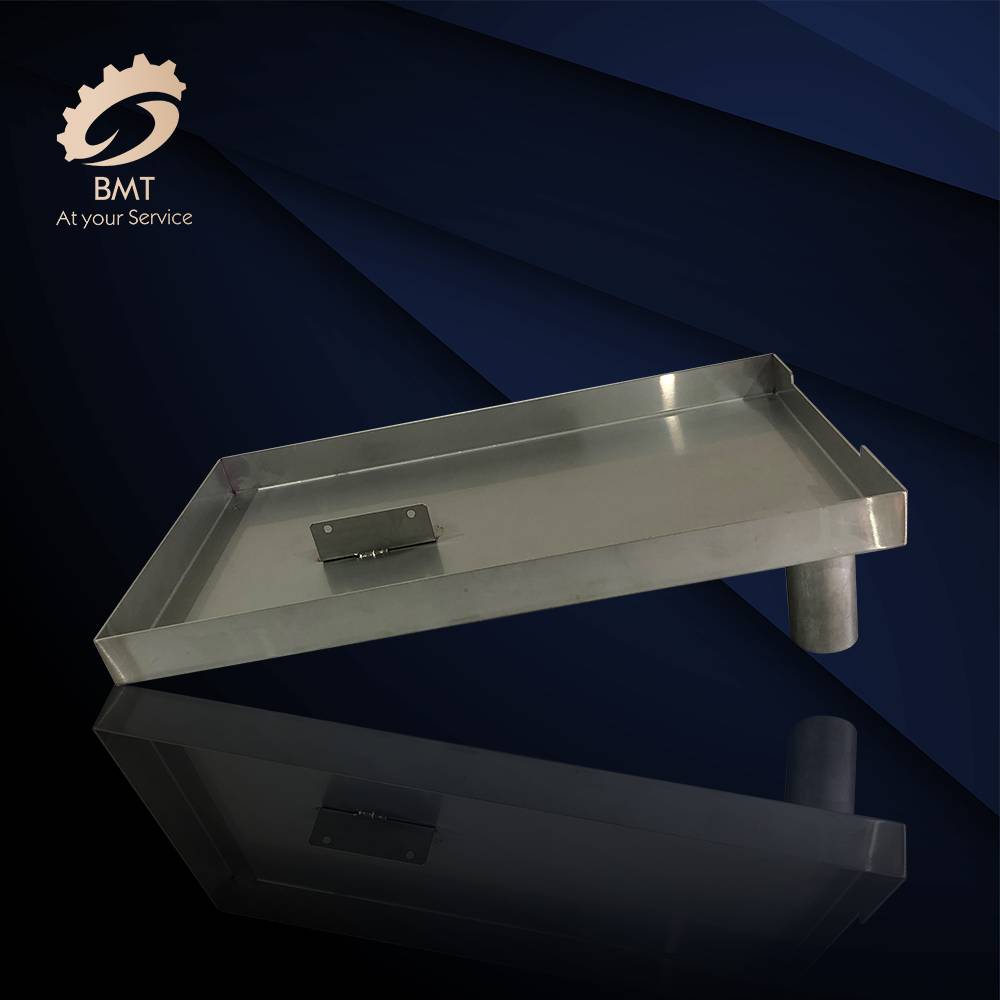

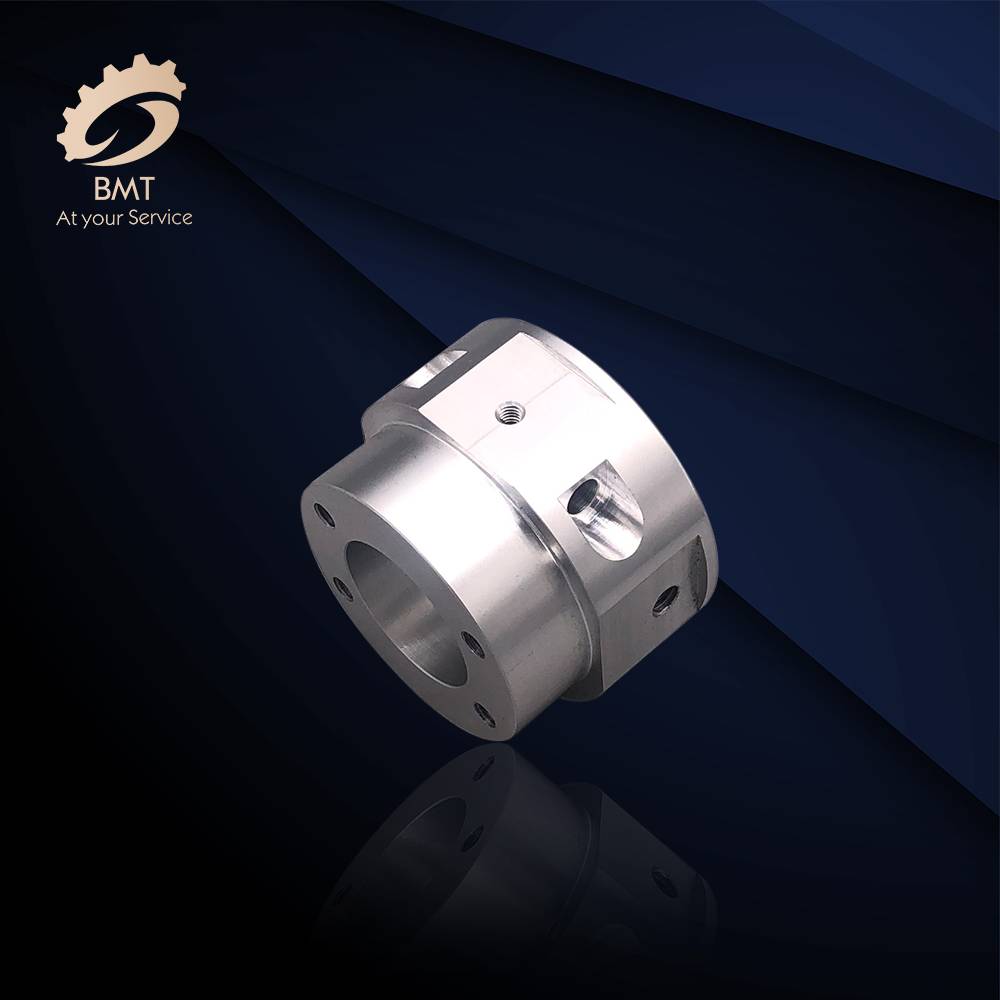

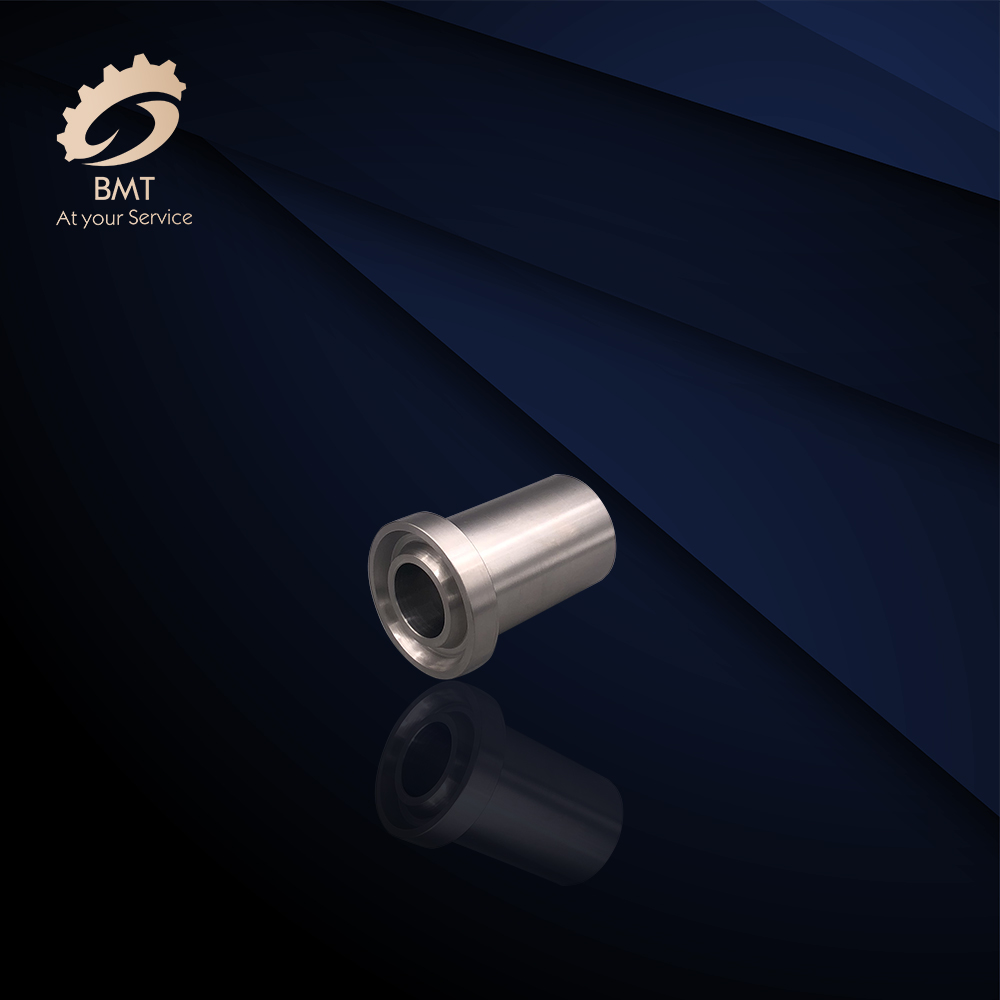

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for 18 Years Factory 5 Axis Cnc Machining - How are These Thin-Walled Parts Produced? – Basile, The product will supply to all over the world, such as: Stuttgart, Bangalore, Greece, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.