2021 China New Design Cnc Precision Components - Mechanical Machining Operating Procedures – Basile Detail:

Mechanical Machining Operating Procedures

Implementation Steps

All operators engaged in various types of machinery must undergo safety technical training and pass the examination before they can take up their jobs.

Before Operation

Strictly use protective equipment according to the regulations before work, tie up the cuffs, scarves and gloves are not allowed, and female workers should wear hats when speaking. The operator must stand on the footrest.

The bolts, travel limits, signals, safety protection (insurance) devices, mechanical transmission parts, electrical parts, and lubrication points of each part should be strictly inspected, and can be started only after they are confirmed to be reliable.

The safety voltage for all types of machine tool lighting applications shall not exceed 36 volts.

In Operation

Workers, clamps, tools and workpieces must be securely clamped. All kinds of machine tools should be idling at low speed after driving, and then the official operation can be started after everything is normal.

It is forbidden to put tools and other things on the machine tool track surface and the worktable. It is not allowed to remove iron filings by hand, and special tools should be used for cleaning.

Before starting the machine tool, observe the surrounding dynamics. After the machine tool starts, stand in a safe position to avoid the moving parts of the machine tool and the splashing of iron filings.

During the operation of various types of machine tools, it is not allowed to adjust the speed change mechanism or stroke. It is not allowed to touch the working surface of the transmission part, the moving workpiece, the tool, etc. during processing. It is not allowed to measure any size during operation. The transmission part of the machine tool transmits or takes tools and other items.

When abnormal noise is found, the machine should be stopped immediately for maintenance, and the machine should not be forced or run with a disease, and the machine tool is not allowed to be overloaded.

During the processing of each machine part, strictly implement the process discipline, see the drawings, see clearly the control points, roughness and technical requirements of relevant parts of each part, and determine the processing procedures of the parts.

The machine should be stopped when adjusting the speed, stroke, clamping workpiece and tool, and wiping the machine. It is not allowed to leave the work post when the machine tool is running. When you want to leave for some reason, you must stop and cut off the power supply.

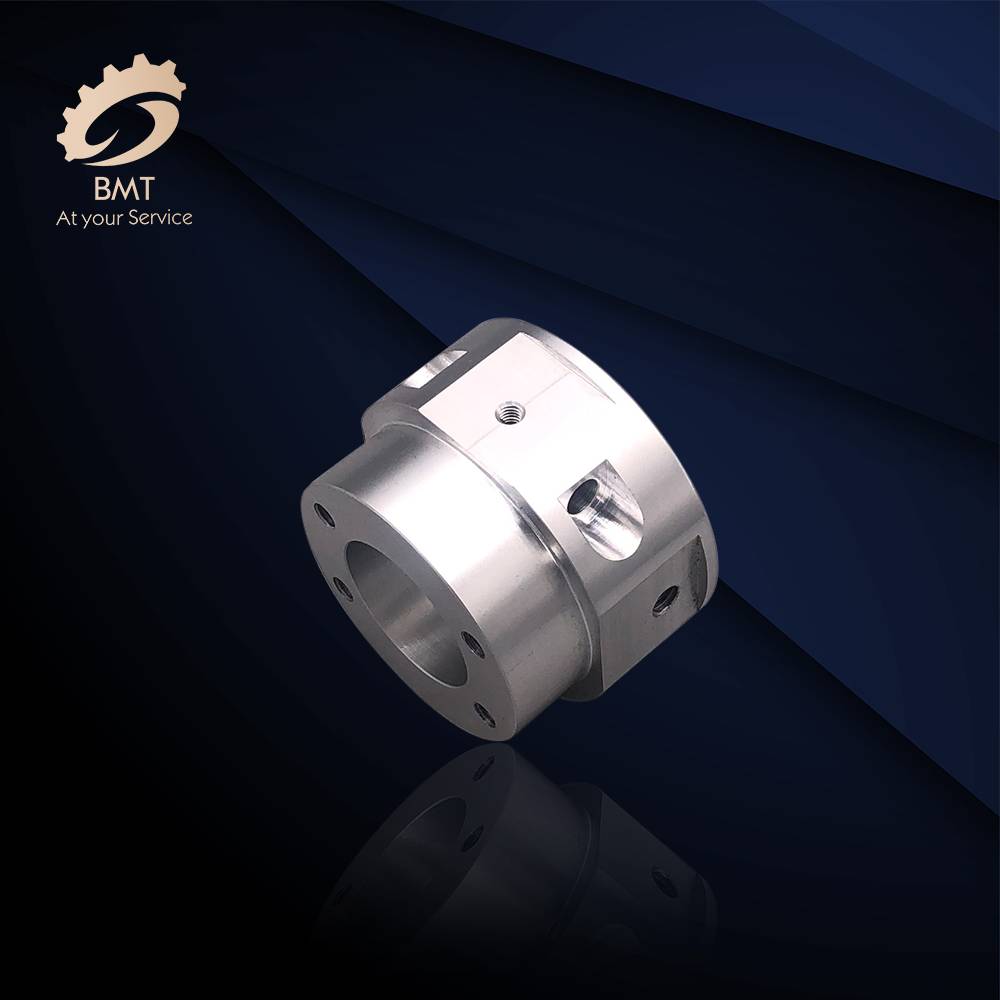

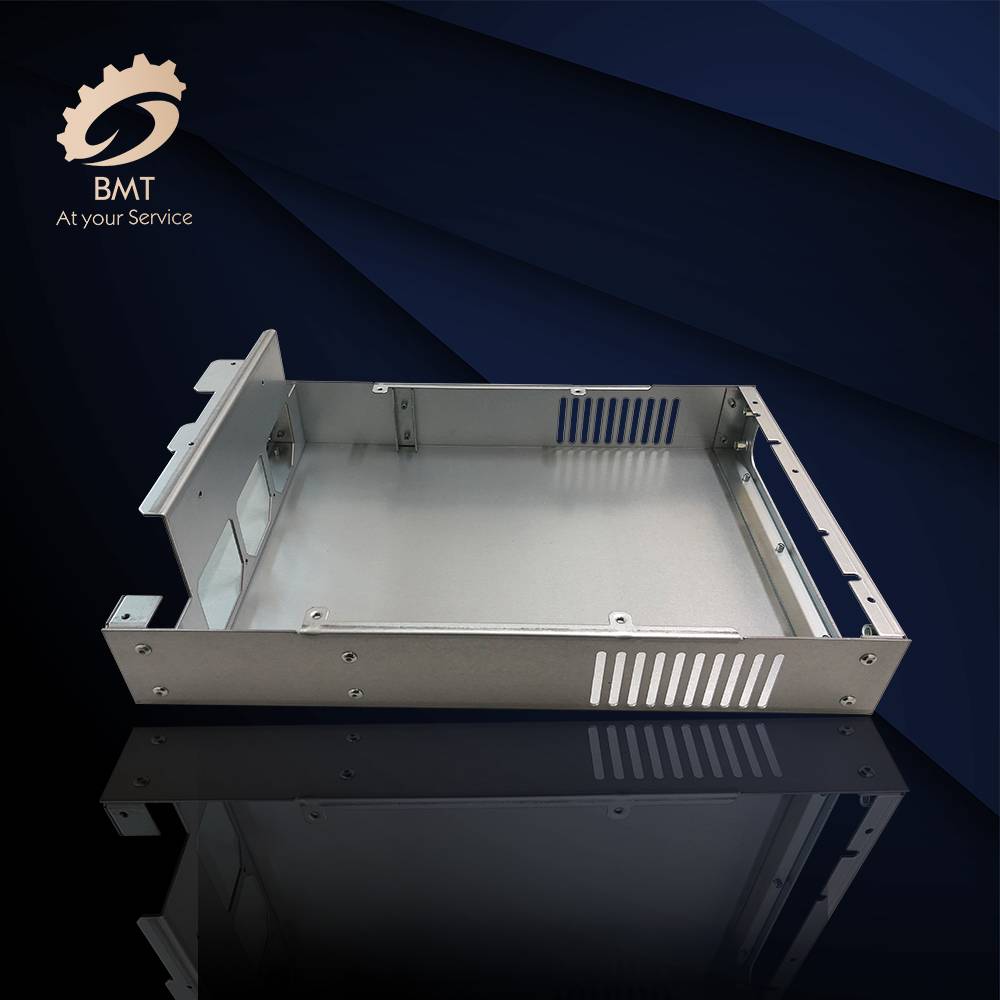

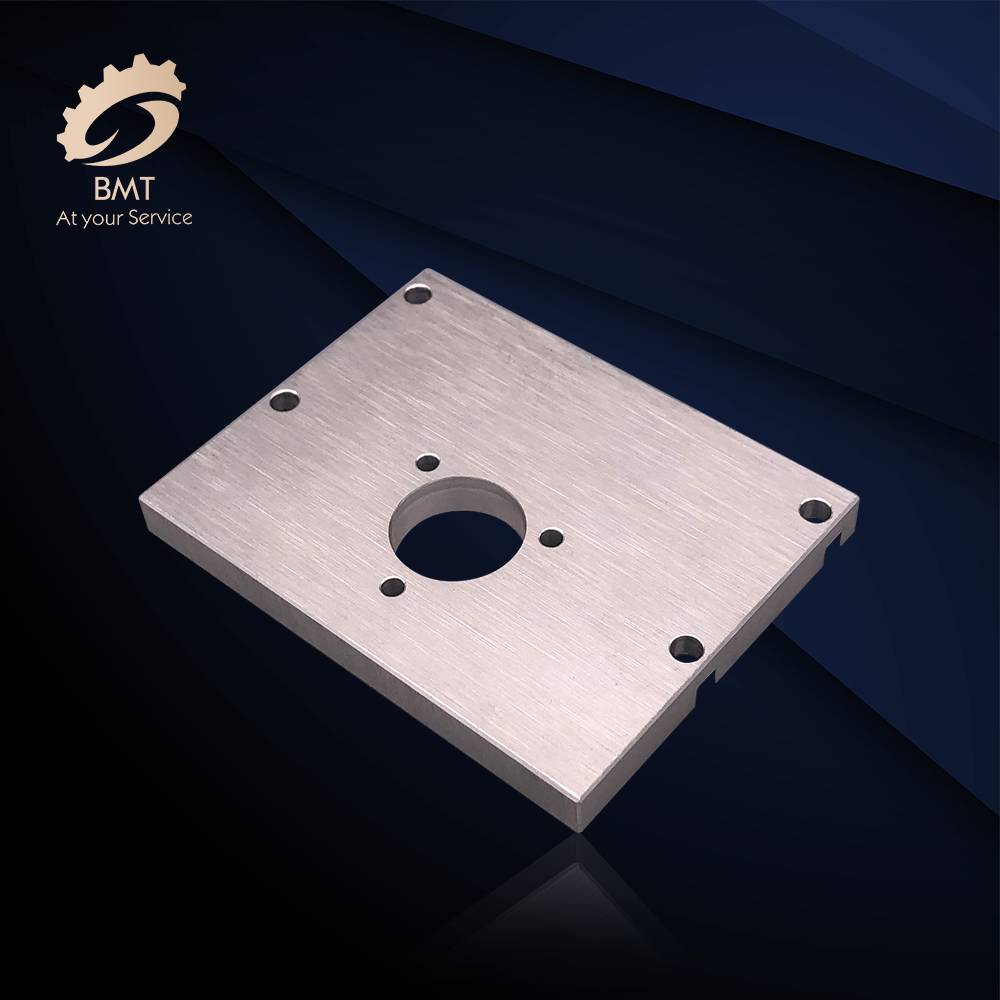

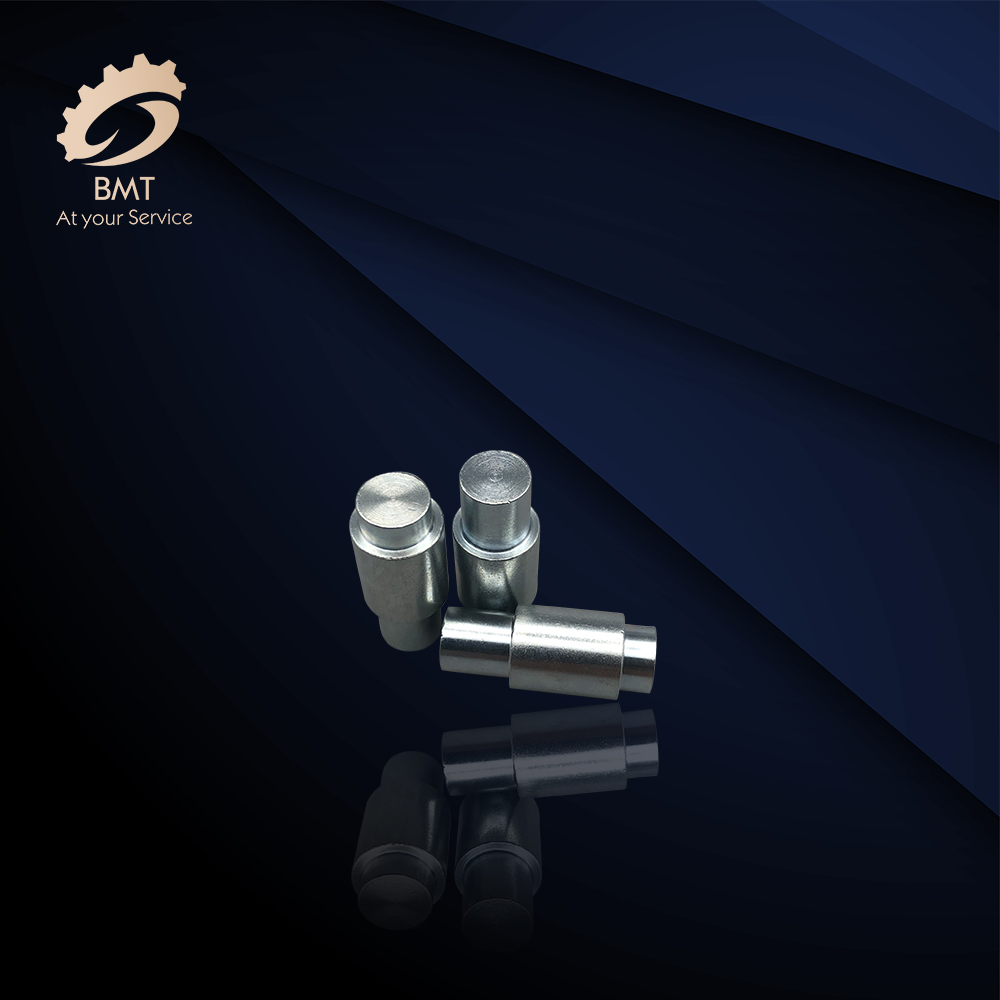

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for 2021 China New Design Cnc Precision Components - Mechanical Machining Operating Procedures – Basile, The product will supply to all over the world, such as: Singapore, Eindhoven, Armenia, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.