Big Discount Cnc Parts Manufacturer - Machining Process Specification – Basile Detail:

Mechanical Machining Operating Procedures 2

After Operation

The raw materials to be processed and the finished products, semi-finished products and wastes must be stacked in the designated place, and all kinds of tools and cutting tools must be kept intact and in good condition.

After the operation, the power must be cut off, the tool must be removed, the handles of each part should be placed in the neutral position, and the switch box should be locked.

The cleaning equipment is hygienic, the iron filings are cleaned, and the guide rails are filled with lubricating oil to prevent corrosion.

Process Specification

Machining process specification is one of the process documents that specifies the machining process and operation methods of parts. After approval, it is used to guide production. The machining process specification generally includes the following contents: the process route of workpiece processing, the specific content of each process and the equipment and process equipment used, the inspection items and inspection methods of the workpiece, the amount of cutting, the time quota, etc.

Steps to Develop a Process Specification

1) Calculate the annual production program and determine the production type.

2) Analyze part drawings and product assembly drawings, and conduct process analysis on parts.

3) Select the blank.

4) Formulate the process route.

5) Determine the machining allowance of each process, and calculate the process size and tolerance.

6) Determine the equipment and tools, fixtures, measuring tools and auxiliary tools used in each process.

7) Determine cutting amount and working hour quota.

8) Determine the technical requirements and inspection methods of each main process.

9) Fill in the craft document.

In the process of formulating process regulations, it is often necessary to adjust the content that has been initially determined in order to improve economic benefits. In the process of implementing the process regulations, unexpected situations may occur, such as changes in production conditions, the introduction of new technologies and new processes, the application of new materials and advanced equipment, etc., all of which require timely revision and improvement of the process regulations. .

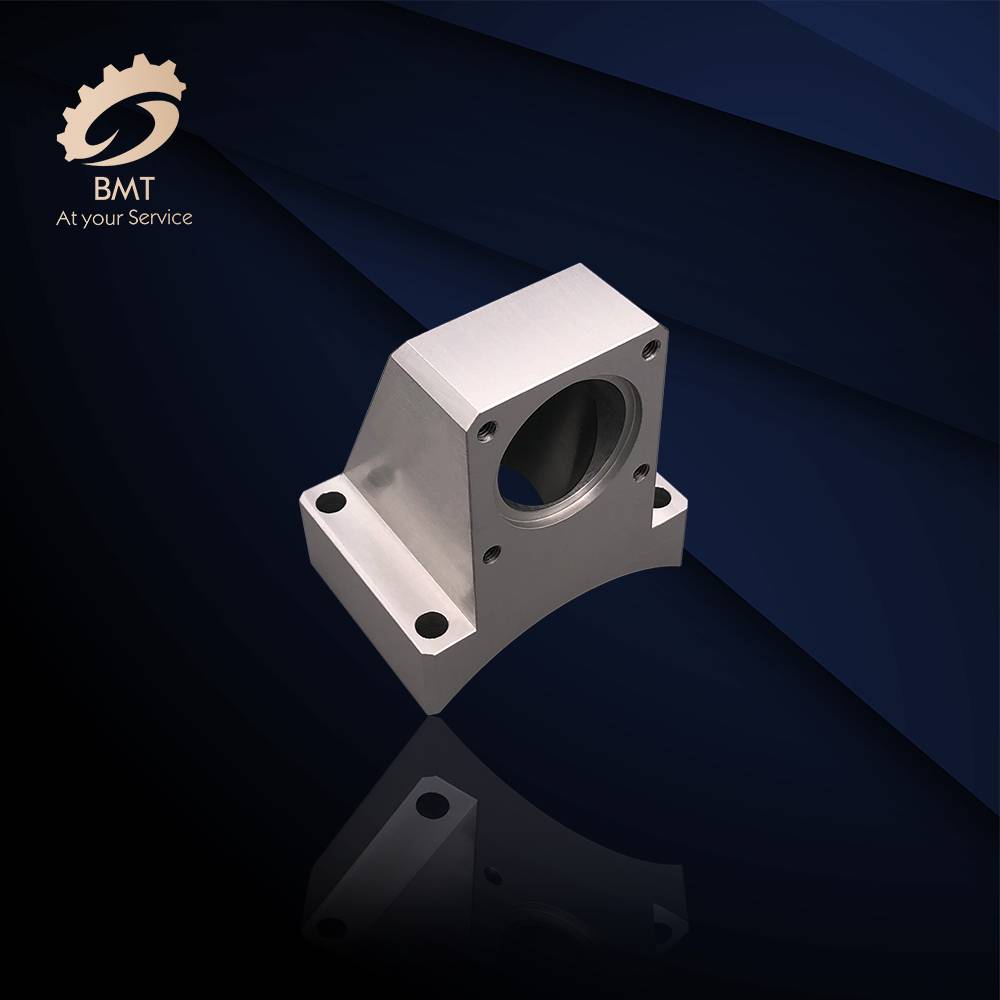

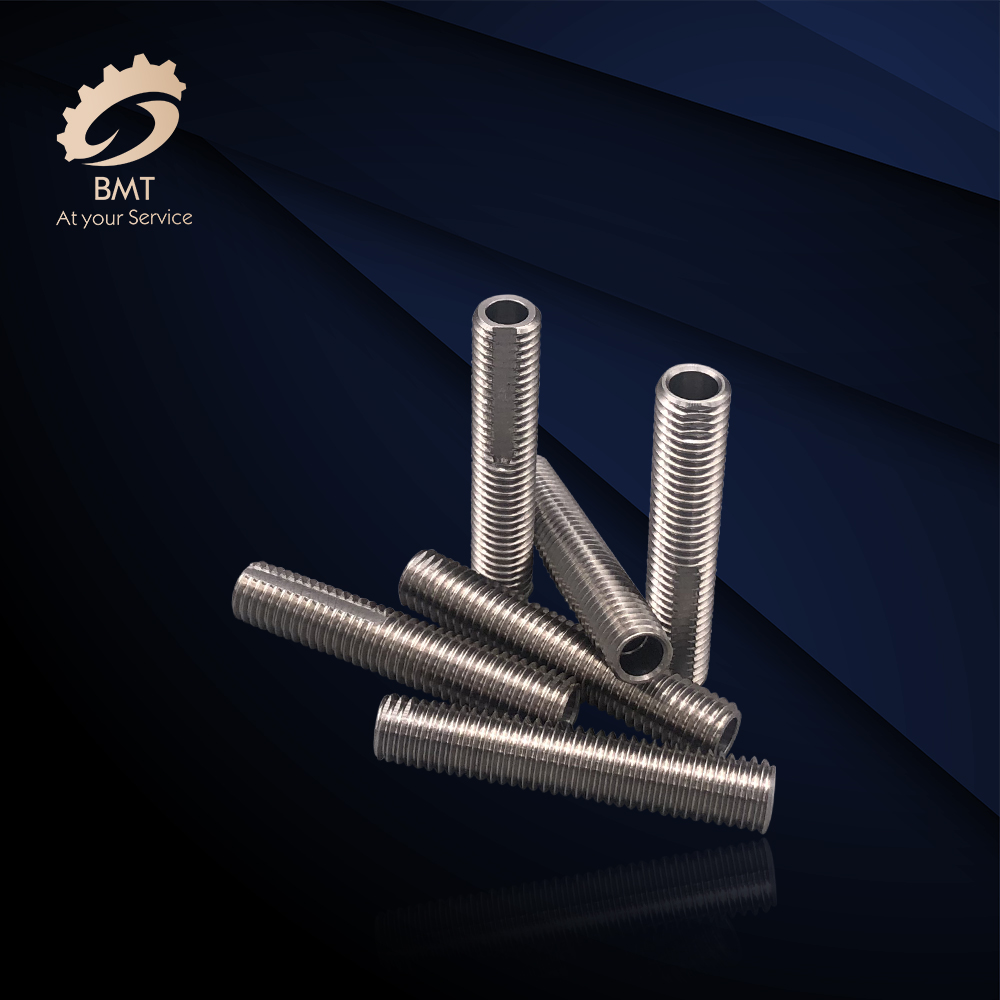

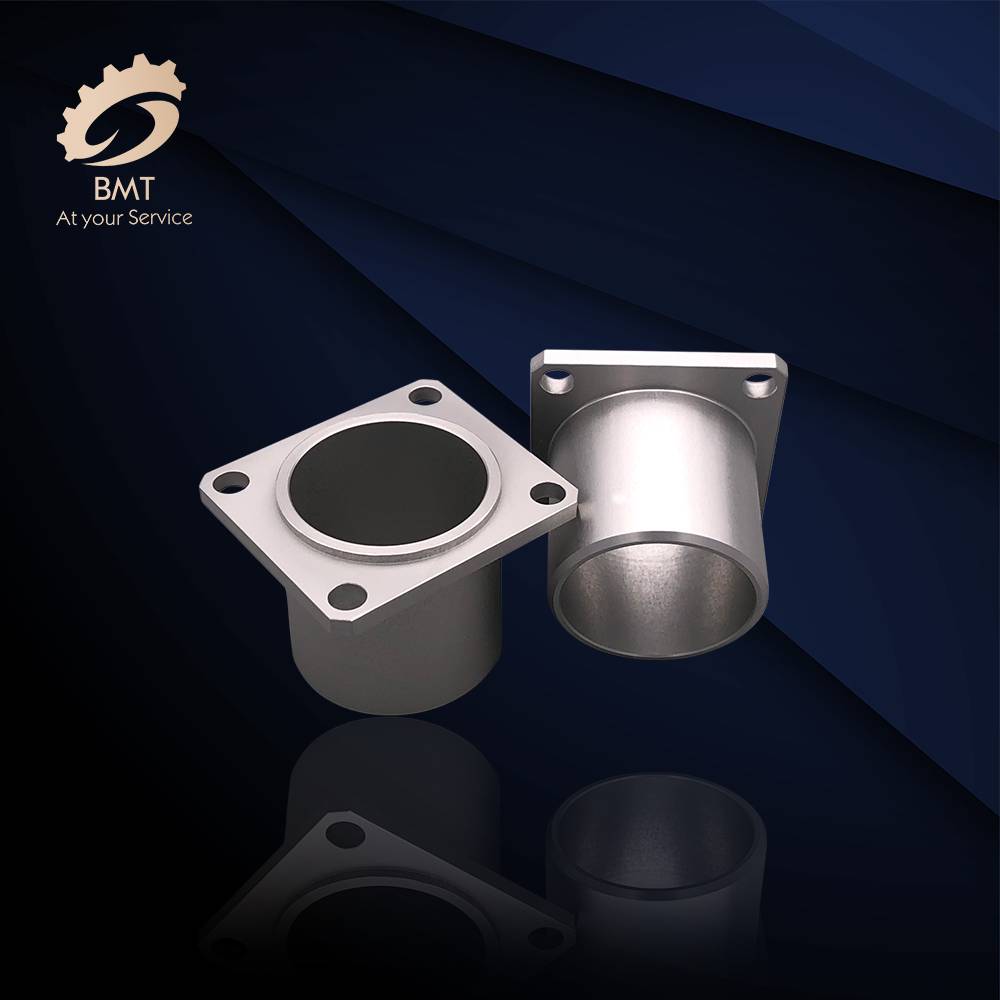

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Big Discount Cnc Parts Manufacturer - Machining Process Specification – Basile, The product will supply to all over the world, such as: Comoros, Birmingham, Switzerland, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Send your message to us:

-

Factory Free sample Mechanical Parts Machining ...

-

Hot New Products Precision Machining Parts - R...

-

China OEM Metal Cnc Services - High Precision ...

-

100% Original Cnc Fabrication Service - Custom...

-

Top Quality 4 Axis Machining - Auto Parts Mach...

-

2021 New Style Diy Cnc Machine Parts - Custom ...