China Supplier Multi Axis Machining - Mechanical Parts Machining – Basile Detail:

BMT CNC Machining Surface Treatment

Sometimes, Customers choose metal surface treatment services after machining at BMT to improve the parts appearance, to get smooth surface, and to reach corrosion resistance, etc. With more than 10 years’ experience with CNC Precision Machining Parts and learned from customers, our customers usually choose Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Heat treatment, Powder Coated, etc. What is the difference between these surface treatments?

|

Electroplating |

A process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts. |

|

|

Polishing |

A process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, make the surface get significant specular reflection or reduce diffuse reflection in some materials. |

|

|

Painting |

Refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation. |

|

|

Passivation |

A common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. |

|

|

Powder coating |

A functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts. |

|

|

Anodizing |

An electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum. |

|

|

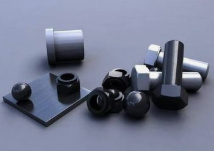

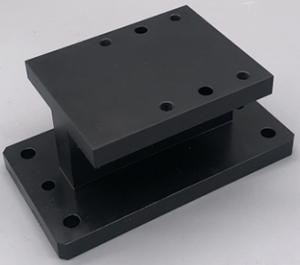

Black oxide |

A chemical process of forming a black conversion coating on stainless steel, copper and copper based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection. |  |

|

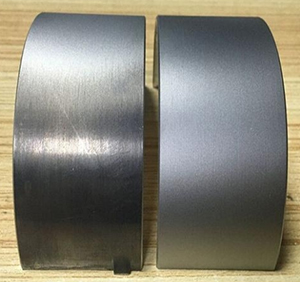

Abrasive blasting/ Sandblasting |

The process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals or increase a texture, then change the smoothness or roughness of surface. |

|

|

Phosphating |

A chemical process for treating the surface of steel, where barely soluble metal-phosphate layers are formed on the base material. The layers created are porous, absorbent and suitable as a conversion layer for subsequent powder coating without further treatment. |  |

BMT also provides grinding, industrial etching, and more custom metal finishing service for presenting the best effect of your part. Just tell us what you need and we will take care of the rest!

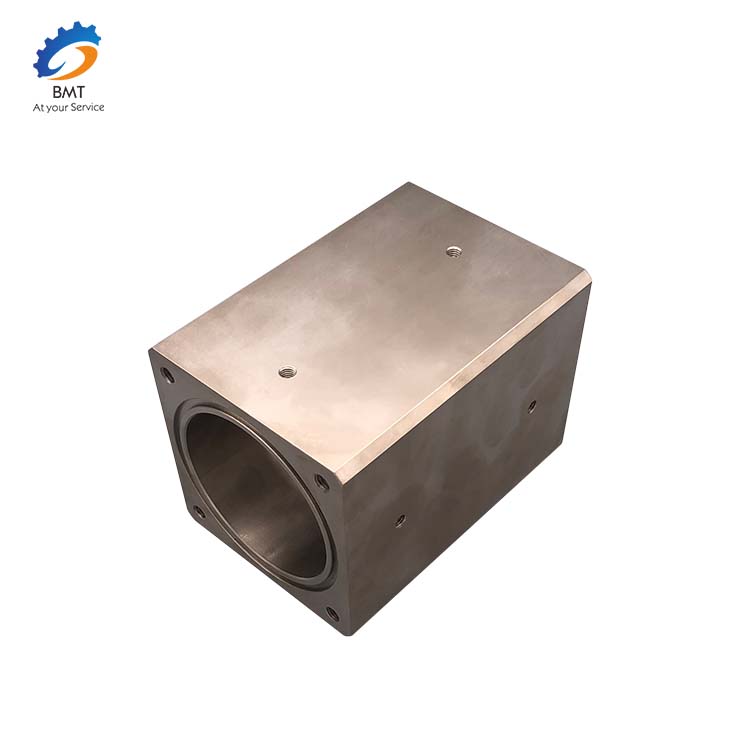

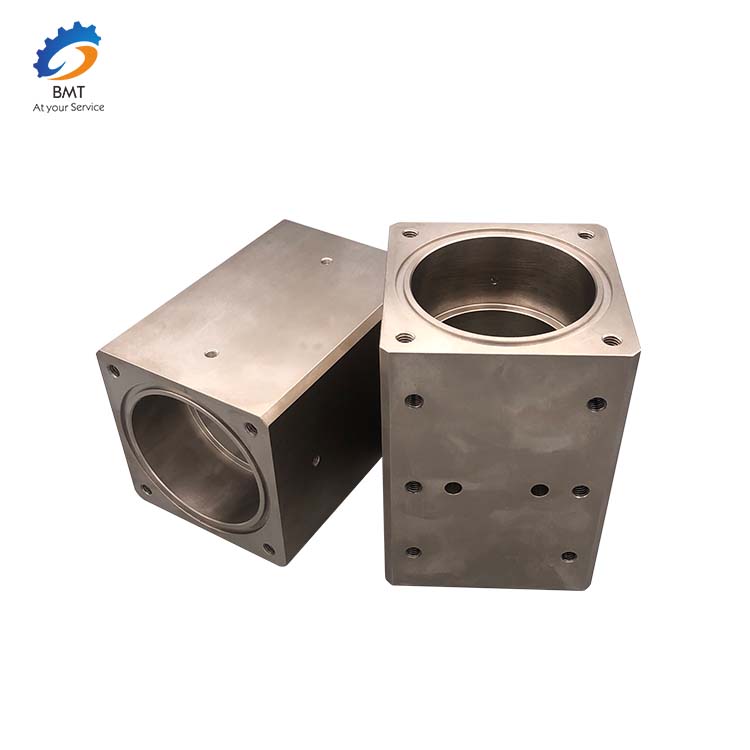

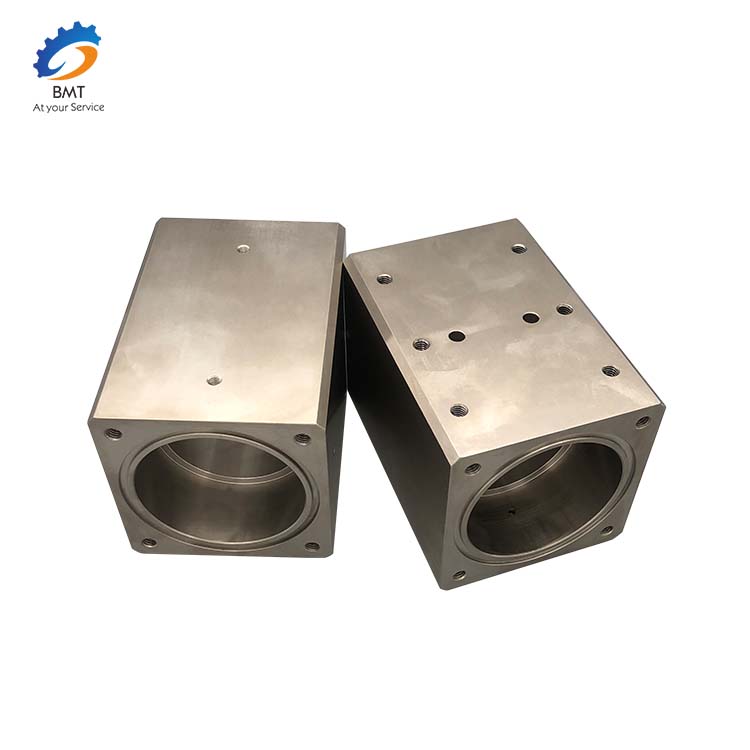

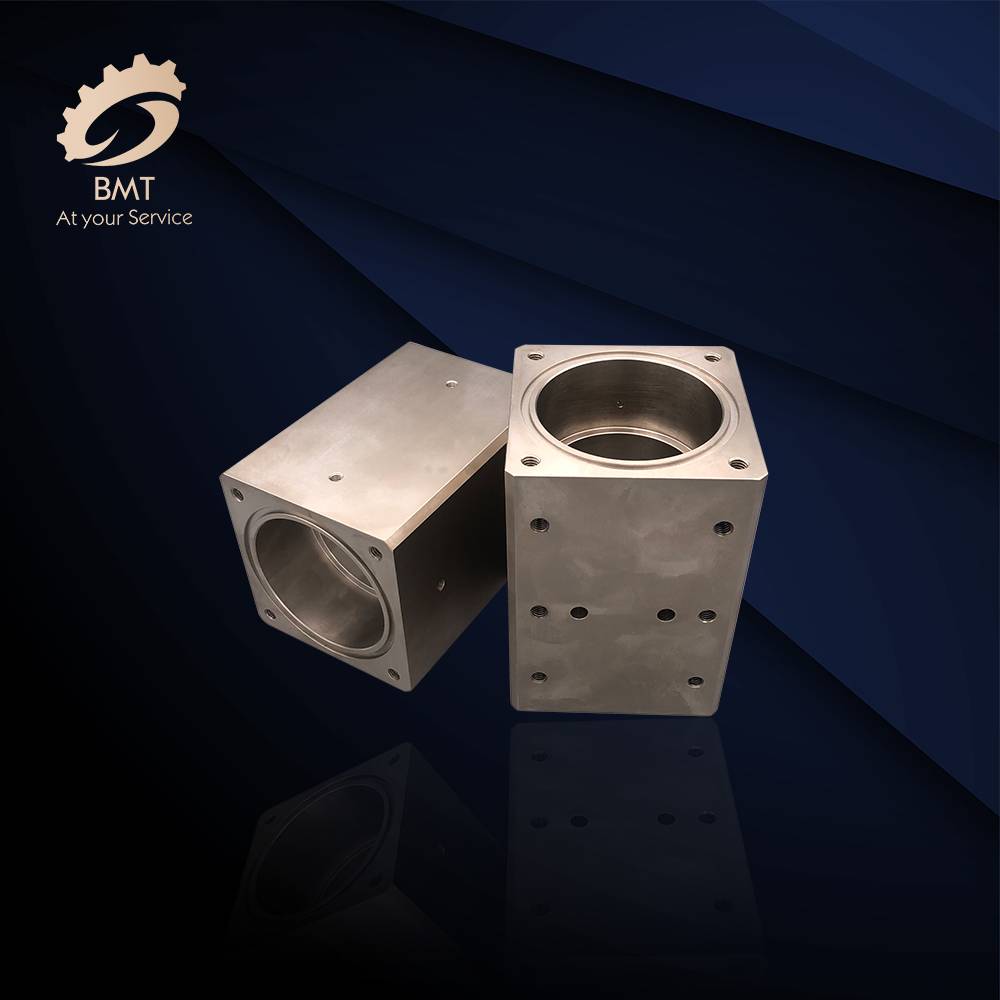

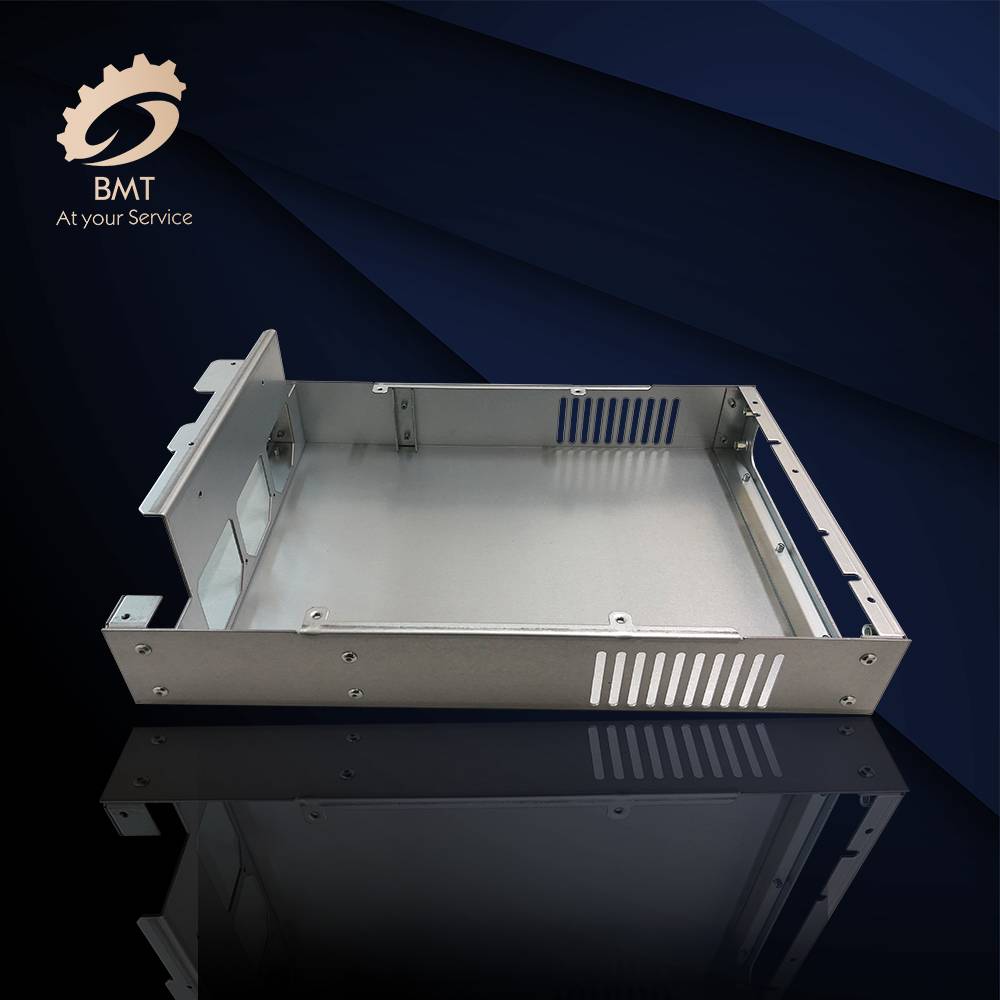

Product Description

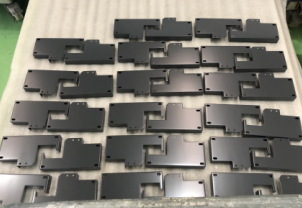

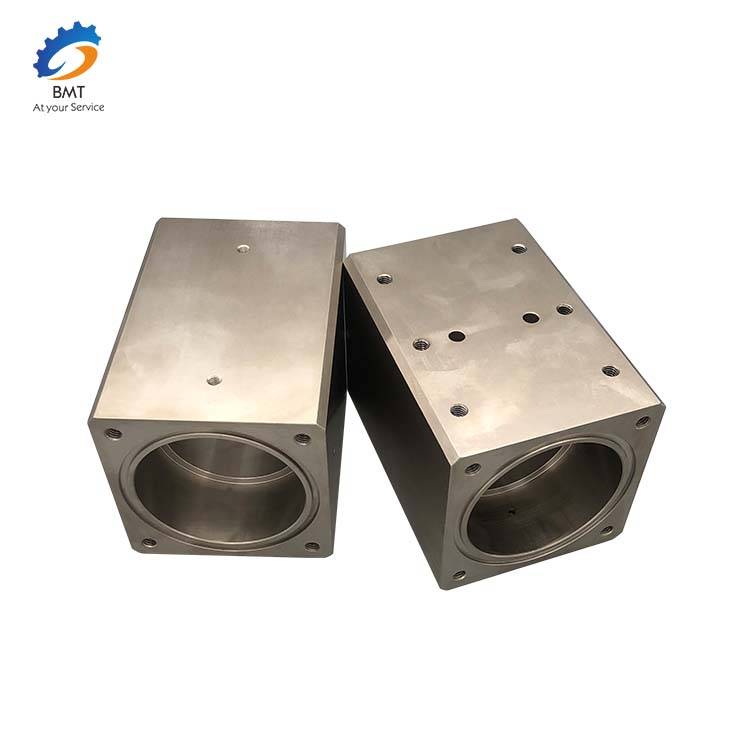

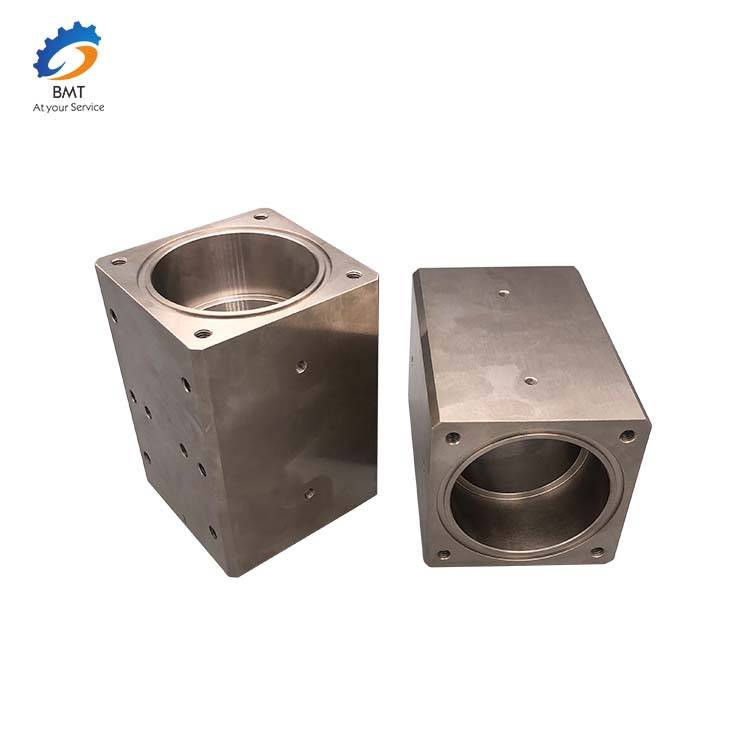

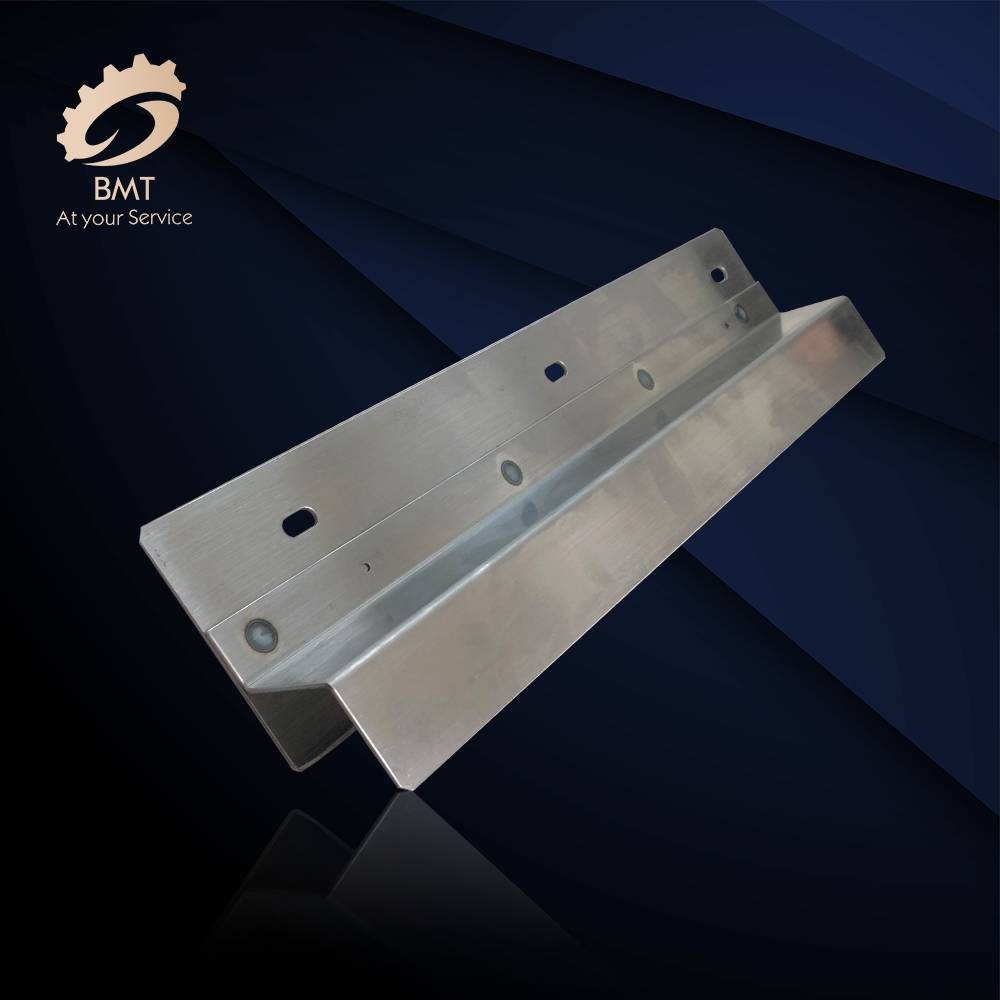

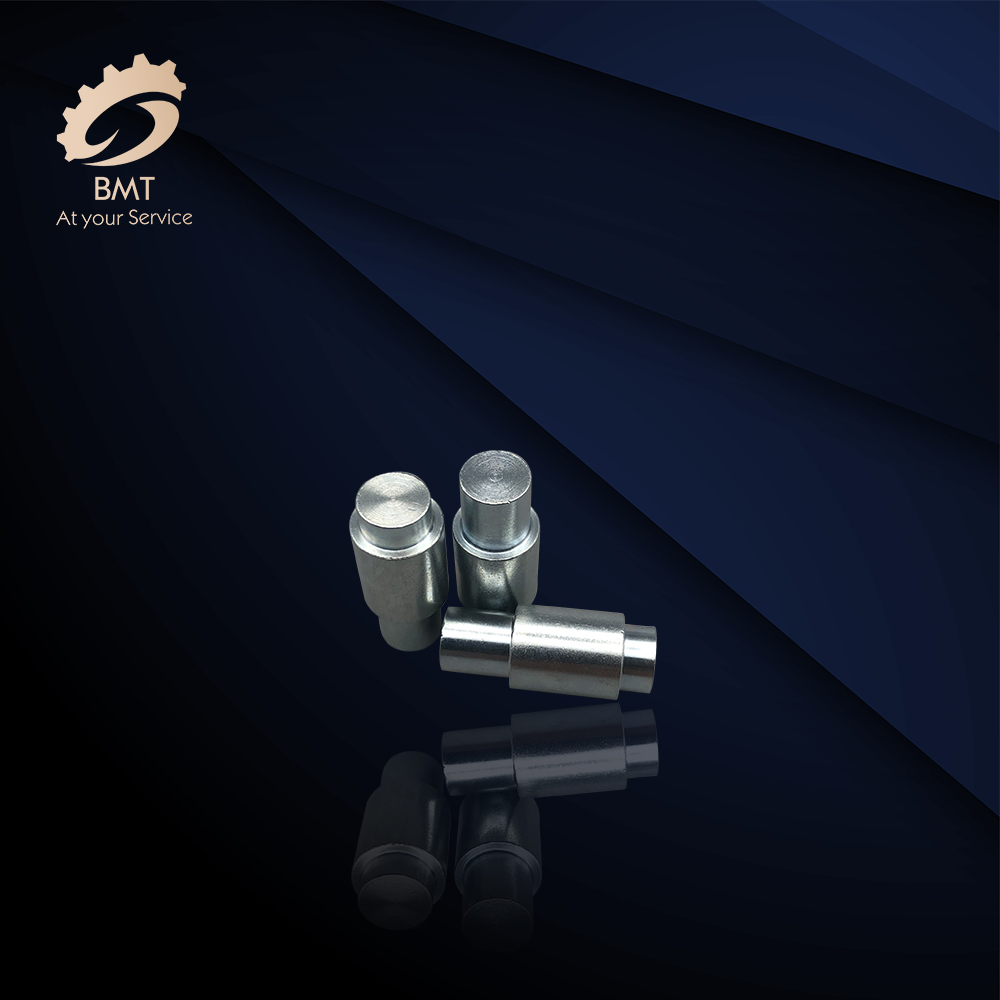

Precision Machining Parts

Precision Machining Parts

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for China Supplier Multi Axis Machining - Mechanical Parts Machining – Basile, The product will supply to all over the world, such as: Manchester, London, Orlando, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

Send your message to us:

-

Factory wholesale Sheet Metal Around Me - Prec...

-

2021 Good Quality Ames Sheet Metal - Customize...

-

Super Lowest Price Custom Metal Fabrication - ...

-

Personlized Products Aluminum Milling Service ...

-

OEM/ODM Supplier Aluminum Stamping Parts Sheet ...

-

Reasonable price Stamped Sheet Metal Parts - C...