Classification of Grinding Machines

With the increase of the number of high-precision and high hardness mechanical parts, as well as the development of precision casting and precision forging technology, the performance, variety and output of grinding machines are constantly improving and growing.

(1) Cylindrical grinder: It is a basic series of ordinary type, mainly used for grinding cylindrical and conical external surfaces.

(2) Internal grinder: It is a common base type series, mainly used for grinding cylindrical and conical internal surfaces.

(3) Coordinate grinder: internal grinder with precise coordinate positioning device.

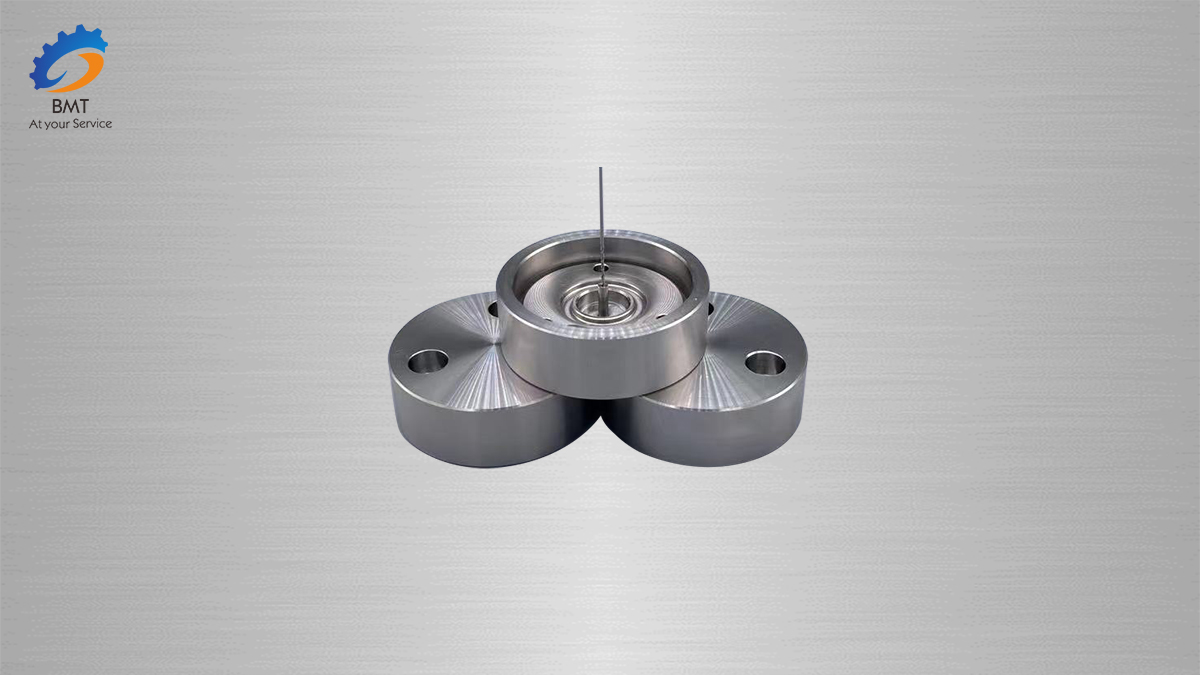

(4) Centerless grinder: The workpiece is clamped centerless, generally supported between the guide wheel and the bracket, and the guide wheel drives the workpiece to rotate. It is mainly used for grinding cylindrical surfaces.

(5) Surface grinder: mainly used for grinding the surface of workpiece.

(6) Abrasive belt grinder: A grinder that uses fast moving abrasive belts for grinding.

(7) Honing machine: It is used for honing various surfaces of workpieces.

(8) Grinder: It is used to grind the inner and outer surfaces of the workpiece plane or cylinder.

(9) Guide rail grinder: mainly used for grinding the guide rail surface of the machine tool.

(10) Tool grinder: A grinder used for grinding tools.

(11) Multi purpose grinding machine: It is used for grinding cylindrical and conical inner and outer surfaces or planes, and can use servo devices and accessories to grind a variety of workpieces.

(12) Special grinding machine: a special machine tool used for grinding certain types of parts. According to its processing objects, it can be divided into spline shaft grinder, crankshaft grinder, cam grinder, gear grinder, thread grinder, curve grinder, etc.

Safety Protection

Grinding is widely used and is one of the main methods for precision machining of machine parts. However, due to the high speed of the grinding wheel of the grinder, the grinding wheel is hard, brittle, and cannot withstand heavy impact. Occasional improper operation will cause very serious consequences if the grinding wheel is broken. Therefore, the safety technical work of grinding is particularly important. Reliable safety protection devices must be adopted, and the operation must be concentrated to ensure that there is no risk.In addition, the fine sand chips and metal chips splashed from the workpiece of the grinding wheel during grinding will harm the workers' eyes. If workers inhale a large amount of this dust, it will be harmful to their health, and appropriate protective measures should also be taken. The following safety technical problems should be paid attention to during grinding.

Send your message to us:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes