CNC Operating Mechanism

Thoroughly check the machine tool before starting, including the inspection of the operating mechanism, electrical equipment, magnetic chuck and other fixtures. After inspection, lubricate it. After lubrication, conduct test run and confirm that everything is in good condition before use. When clamping the workpiece, pay attention to its alignment and clamping.

Loose workpiece during grinding will cause serious consequences such as workpiece flying out, hurting people or crushing the grinding wheel. When starting to work, use manual adjustment to make the grinding wheel slowly close to the workpiece. The starting feed should be small, and excessive force is not allowed to prevent the grinding wheel from colliding. When it is necessary to control the reciprocating motion of the workbench with a stopper, it shall be accurately adjusted according to the grinding length of the workpiece, and the stopper shall be firmly fastened.

When replacing the grinding wheel, the appearance must be checked first to see if there is any damage, and then the grinding wheel shall be knocked with a wooden hammer or stick. The sound shall be clear and clear without cracks. When installing the grinding wheel, it must be assembled according to the specified methods and requirements. After the static balance commissioning, it shall be installed and tested. It can only be used after everything is normal.

Workers shall wear safety glasses during work, and the grinding wheel shall be trimmed in a balanced manner to prevent impact. Measure the workpiece, adjust or wipe the machine tool after shutdown. When using the magnetic chuck, the disk surface and the workpiece shall be wiped, tightened and firmly sucked.

If necessary, a stopper can be added to prevent the workpiece from shifting or flying out. Attention shall be paid to installing the protective cover of the grinding wheel or the baffle of the machine tool, and the side of the station shall rotate the front of the grinding wheel at high speed.

Send your message to us:

-

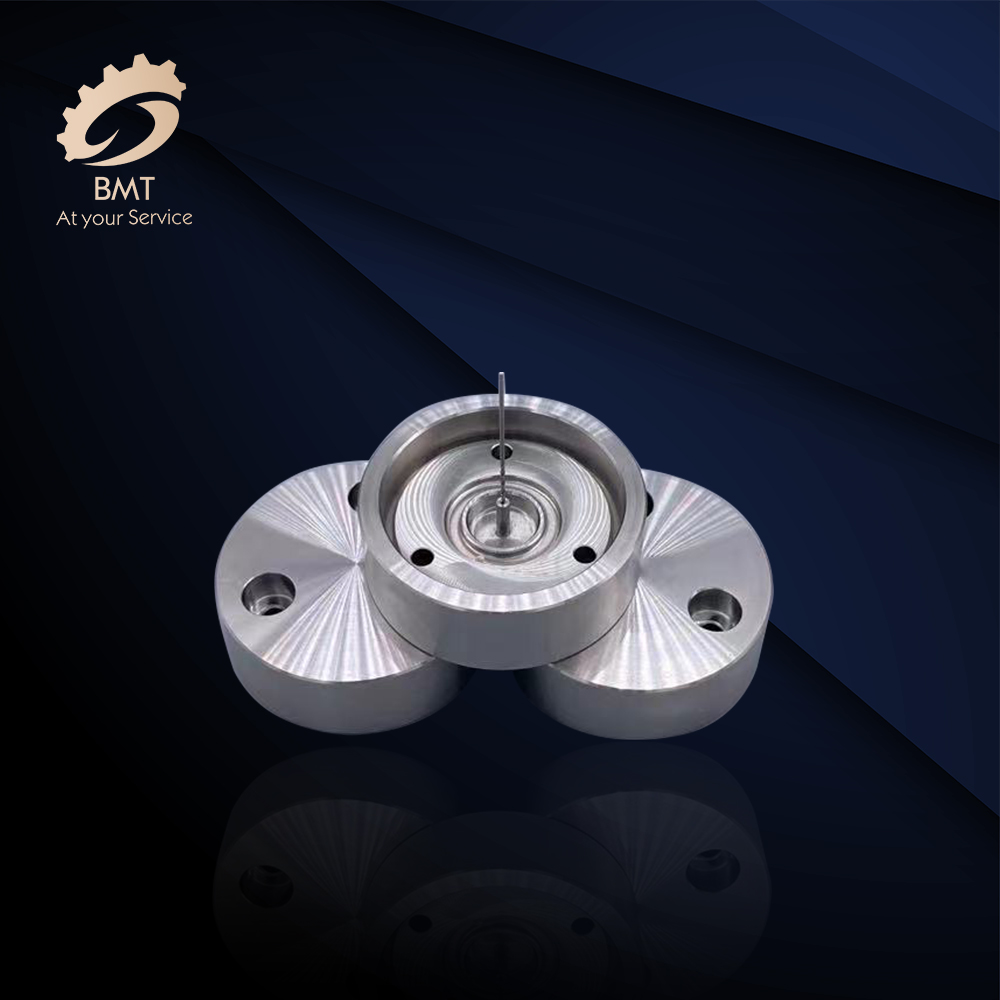

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes