CNC Machining Clamping Skills

Machining Part Clamping:

The basic principle of folding positioning installation

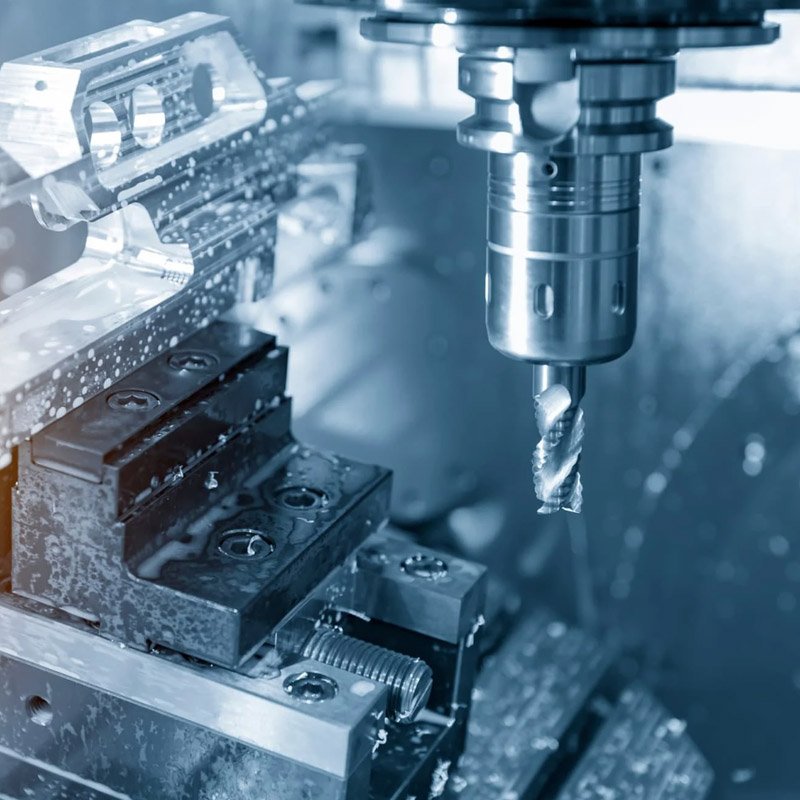

When machining parts on a CNC machine tool, the basic principle of positioning and installation is to choose a reasonable positioning datum and clamping plan. Pay attention to the following points when choosing:

1. Strive for a unified benchmark for design, process and programming calculations.

2. Minimize the number of clamping times, and process all the surfaces to be processed after positioning and clamping once as much as possible.

3. Avoid the use of machine-occupied manual adjustment processing schemes to give full play to the effectiveness of CNC machine tools.

The basic principles of folding and selecting fixtures

The characteristics of CNC machining put forward two basic requirements for the fixture: one is to ensure that the coordinate direction of the fixture is relatively fixed with the coordinate direction of the machine tool; the other is to coordinate the size relationship between the parts and the machine tool coordinate system. In addition, the following points should be considered:

1. When the batch of parts is not large, modular fixtures, adjustable fixtures and other general fixtures should be used as much as possible to shorten production preparation time and save production costs.

2. Only consider the use of special fixtures during mass production, and strive to have a simple structure.

3. The loading and unloading of parts should be fast, convenient and reliable to shorten the machine stop time.

4. The parts on the fixture should not hinder the machining of the surface of the parts by the machine tool, that is, the fixture should be opened, and its positioning and clamping mechanism components should not affect the knife during processing (such as collisions, etc.).

Machining error

Numerical control machining error addition is composed of programming error editing, machine tool error machine, positioning error fixed, tool setting error tool and other errors.

1. Programming error is composed of approximation error δ and rounding error. The approximation error δ is produced in the process of approximating a non-circular curve with a straight line segment or a circular arc segment, as shown in Figure 1.43. The rounding error is the error produced by rounding the coordinate value to an integer pulse equivalent value during data processing. Pulse equivalent refers to the displacement of each unit pulse corresponding to the coordinate axis. Normal-precision CNC machine tools generally have a pulse equivalent value of 0.01mm; more precise CNC machine tools have a pulse equivalent value of 0.005mm or 0.001mm, etc.

2. The error of the machine tool is caused by the error of the CNC system and the feed system.

3. The positioning error is always caused when the workpiece is positioned on the fixture and the fixture is positioned on the machine tool.

4. Tool setting error tool is generated when determining the relative position of the tool and the workpiece.