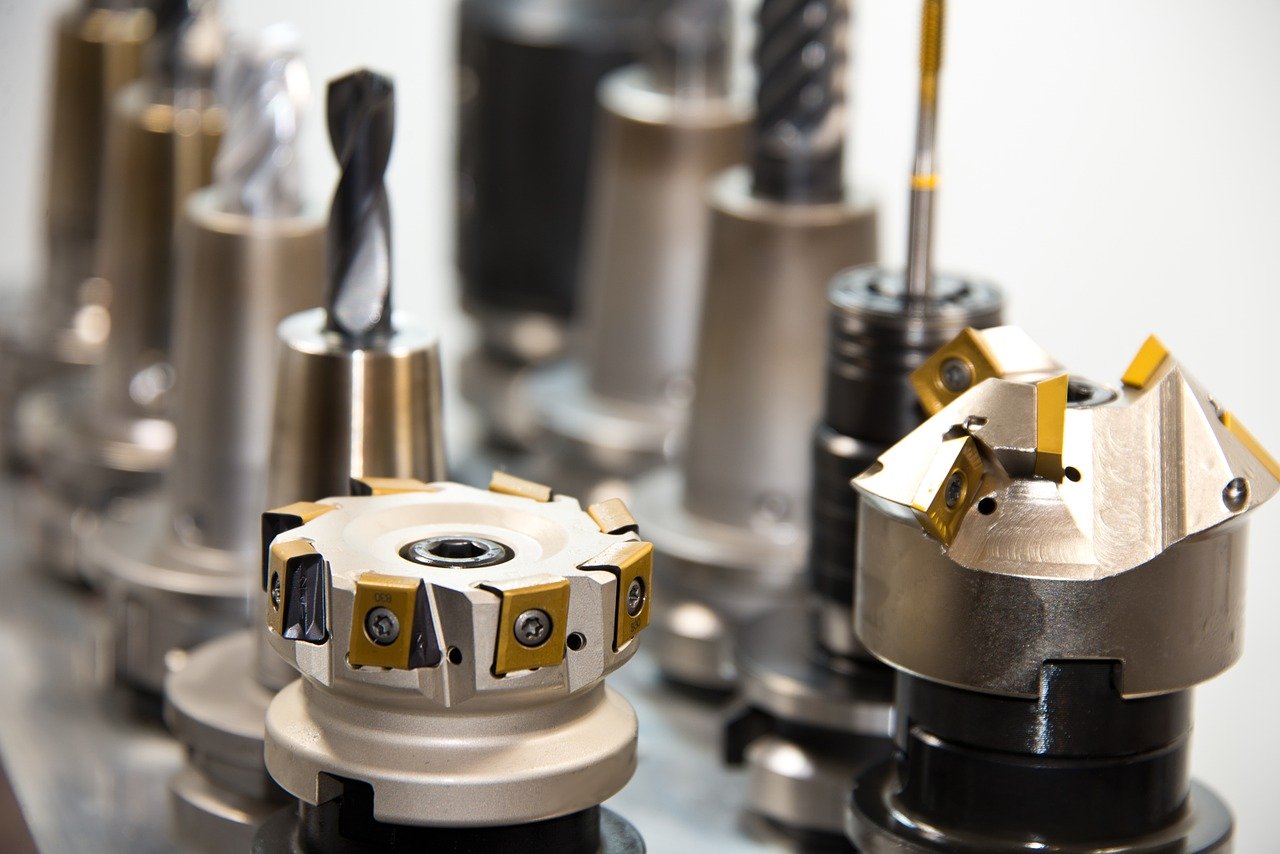

Tools Selection of CNC Machining

The Principle of Choosing CNC Tools

Tool life is closely related to cutting volume. When formulating cutting parameters, the reasonable tool life should be selected first, and the reasonable tool life should be determined according to the optimization goal. Generally divided into the highest productivity tool life and the lowest cost tool life, the former is determined according to the goal of the least single-piece man-hours, and the latter is determined according to the goal of the lowest process cost.

When choosing tools, you can consider the following points according to the complexity of the tool, manufacturing and grinding costs. The life of complex and high-precision tools should be higher than that of single-edged tools. For machine clamp indexable tools, due to the short tool change time, in order to give full play to its cutting performance and improve production efficiency, the tool life can be selected to be lower, generally 15-30min. For multi-tools, modular machine tools and automated machining tools with complex tool installation, tool change, and tool adjustment, the tool life should be higher, and the reliability of the tool should be ensured in particular.

When the productivity of a certain process in the workshop limits the improvement of the productivity of the entire workshop, the tool life of the process should be selected lower. When the cost of the whole plant per unit time of a certain process is relatively large, the tool life should also be selected Lower. When finishing large parts, in order to ensure that at least one pass is completed, and to avoid changing the tool in the middle of cutting, the tool life should be determined according to the accuracy of the part and the surface roughness. Compared with ordinary machine tool processing methods, CNC machining puts forward higher requirements on cutting tools.

It not only requires good quality and high precision, but also requires dimensional stability, high durability, and easy installation and adjustment. Meet the high efficiency requirements of CNC machine tools. The selected tools on CNC machine tools often use tool materials suitable for high-speed cutting (such as high-speed steel, ultra-fine-grained cemented carbide) and use indexable inserts.

Choose Tools for CNC Turning

Commonly used CNC turning tools are divided into three types: forming tools, pointed tools, arc tools and three types. Forming turning tools are also called prototype turning tools, and the contour shape of the machined parts is completely determined by the shape and size of the cutting edge of the turning tool. In CNC turning processing, common forming turning tools include small radius arc turning tools, non-rectangular turning tools and threading tools. In CNC machining, the forming turning tool should be used as little as possible or not. The pointed turning tool is a turning tool characterized by a straight cutting edge.

The tip of this type of turning tool is composed of linear main and secondary cutting edges, such as 900 internal and external turning tools, left and right end face turning tools, grooving (cutting) turning tools, and various external and internal cutting edges with small tip chamfers. Hole turning tool. The selection method of the geometric parameters of the pointed turning tool (mainly the geometric angle) is basically the same as that of ordinary turning, but the characteristics of CNC machining (such as machining route, machining interference, etc.) should be considered comprehensively, and the tool tip itself should be considered strength.

The second is the arc-shaped turning tool. The arc-shaped turning tool is a turning tool characterized by an arc-shaped cutting edge with a small roundness or line profile error. Each point of the arc edge of the turning tool is the tip of the arc-shaped turning tool. Accordingly, the tool position point is not on the arc, but on the center of the arc. The arc-shaped turning tool can be used for turning inner and outer surfaces, and is particularly suitable for turning various smoothly connected (concave) forming surfaces. When selecting the arc radius of the turning tool, it should be considered that the arc radius of the cutting edge of the two-point turning tool should be less than or equal to the minimum curvature radius on the concave contour of the part, so as to avoid processing dryness. The radius should not be selected too small, otherwise it will not only be difficult to manufacture, The turning tool may also be damaged due to weak tool tip strength or poor heat dissipation capacity of the tool body.