Factory Price Basic Components Of Cnc - Stainless Steel and CNC Machining – Basile Detail:

Stainless Steel and CNC Machining

Stainless steel is an incredibly versatile metal and is often used for CNC Machining and CNC turning in the aerospace, automotive and marine industries. Stainless steel is known for its resistance to corrosion and with various alloys and grades of stainless steel available, there are a wide variety of applications and use cases.

There are five general categories of stainless steel with different alloying elements and material structures:

- Austenitic Stainless Steel

- Ferritic Stainless Steel

- Martensitic Stainless Steel

- Precipitation Hardened Steel

- Duplex Stainless Steel (Austenitic-Ferritic)

Austenitic steel

Austenitic stainless steels are primarily used for products that require strong corrosion resistance. Domestic, industrial and architectural products often use austenitic stainless steel. These could include:

1.Nuts and bolts and other fasteners;

2.Food processing equipment;

3.Industrial Gas Turbines.

Austenitic stainless steels are known for their machinability and weldability, which mean they are often used in CNC machining. Due to its mainly crystalline structure, austenitic stainless steel cannot be hardened by heat, and makes them non-magnetic. Popular grades include 304 and 316, and contain between 16 and 26 percent chromium.

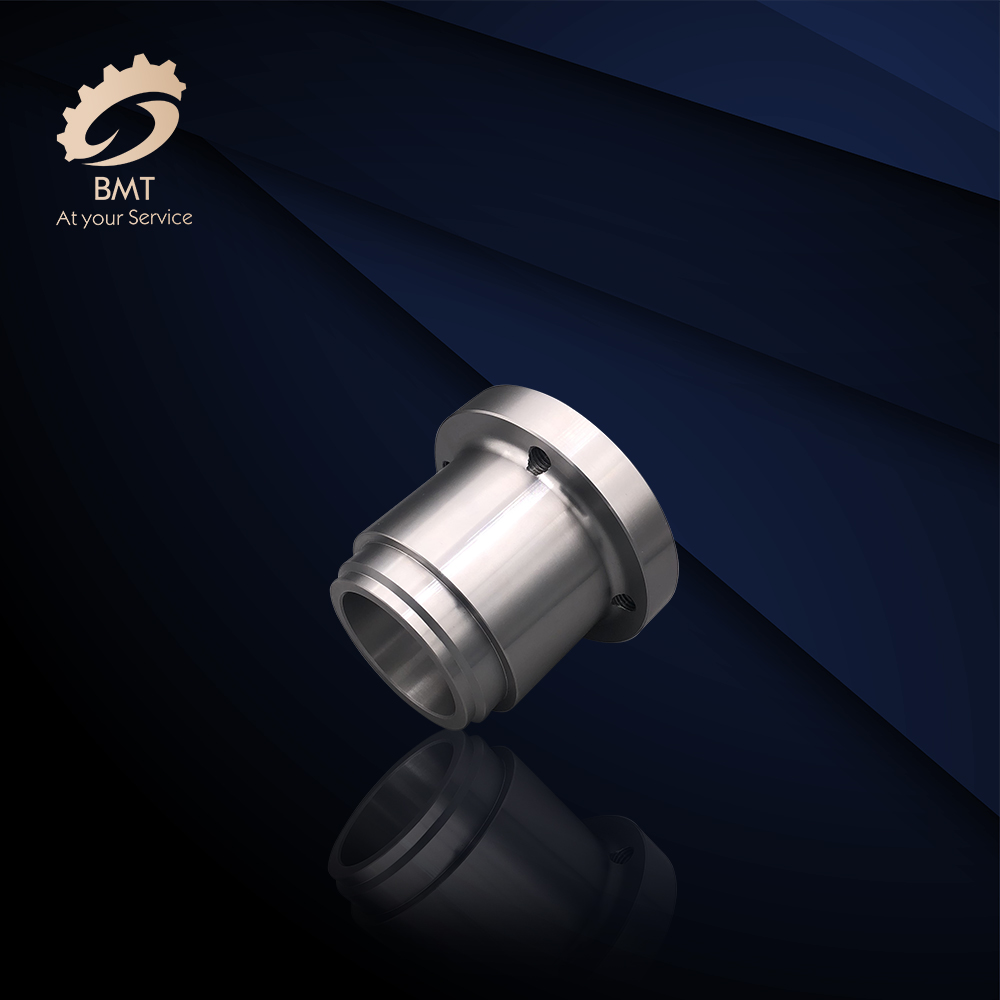

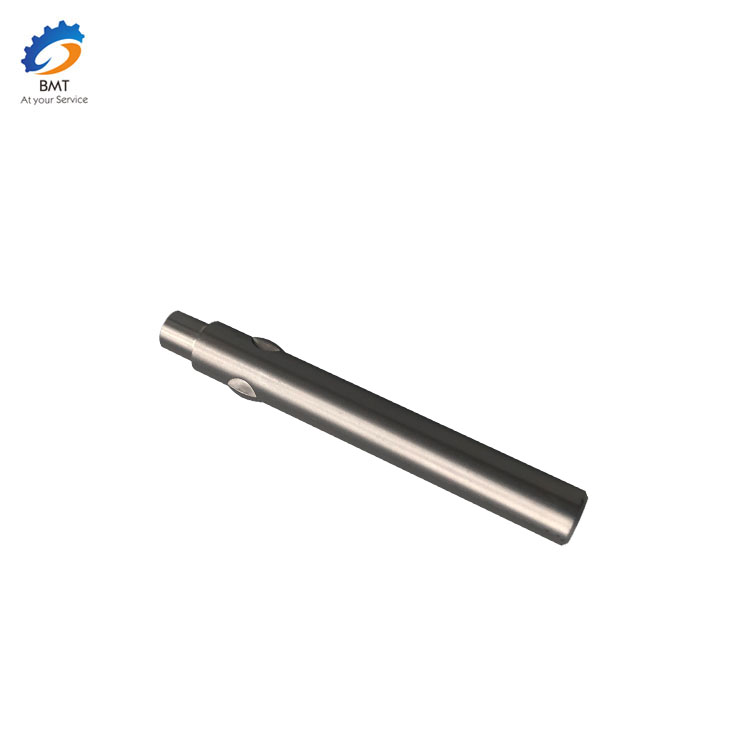

Product Description

CNC Machining Parts

CNC Machining Parts

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Factory Price Basic Components Of Cnc - Stainless Steel and CNC Machining – Basile, The product will supply to all over the world, such as: Iran, Angola, venezuela, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.