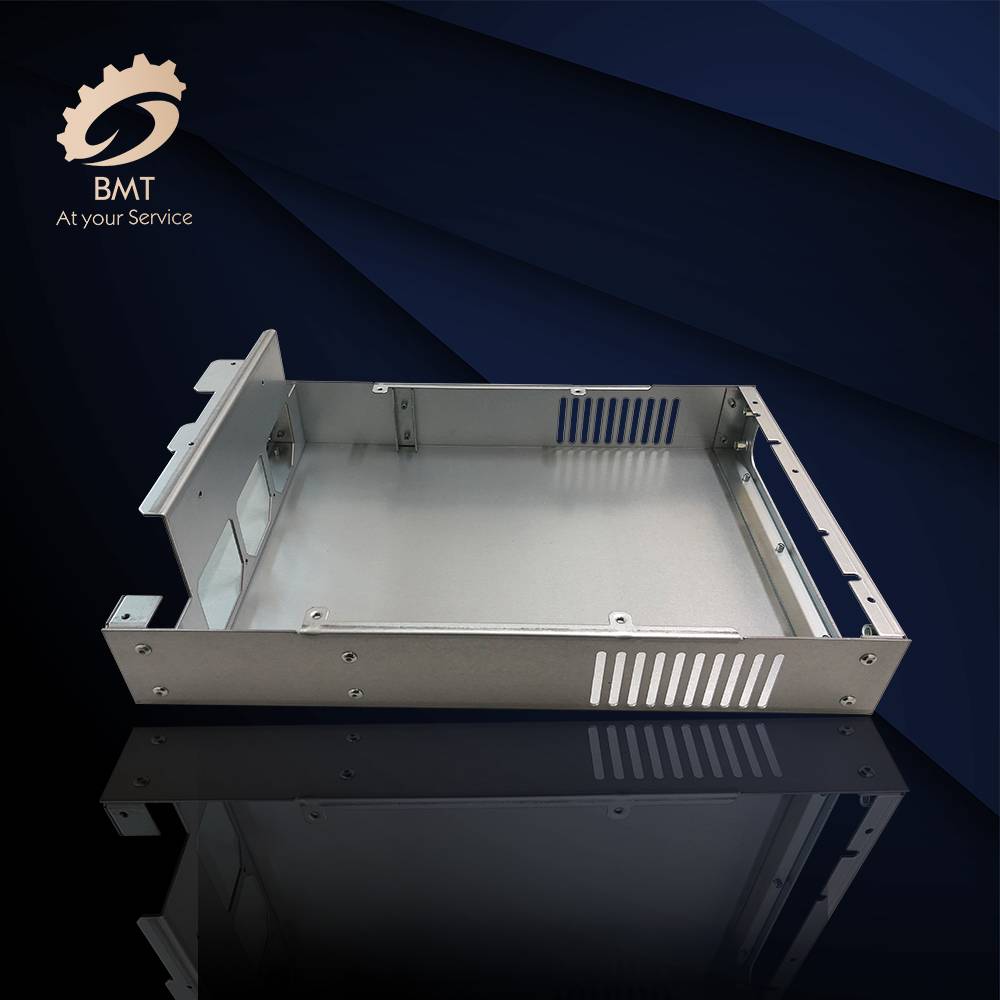

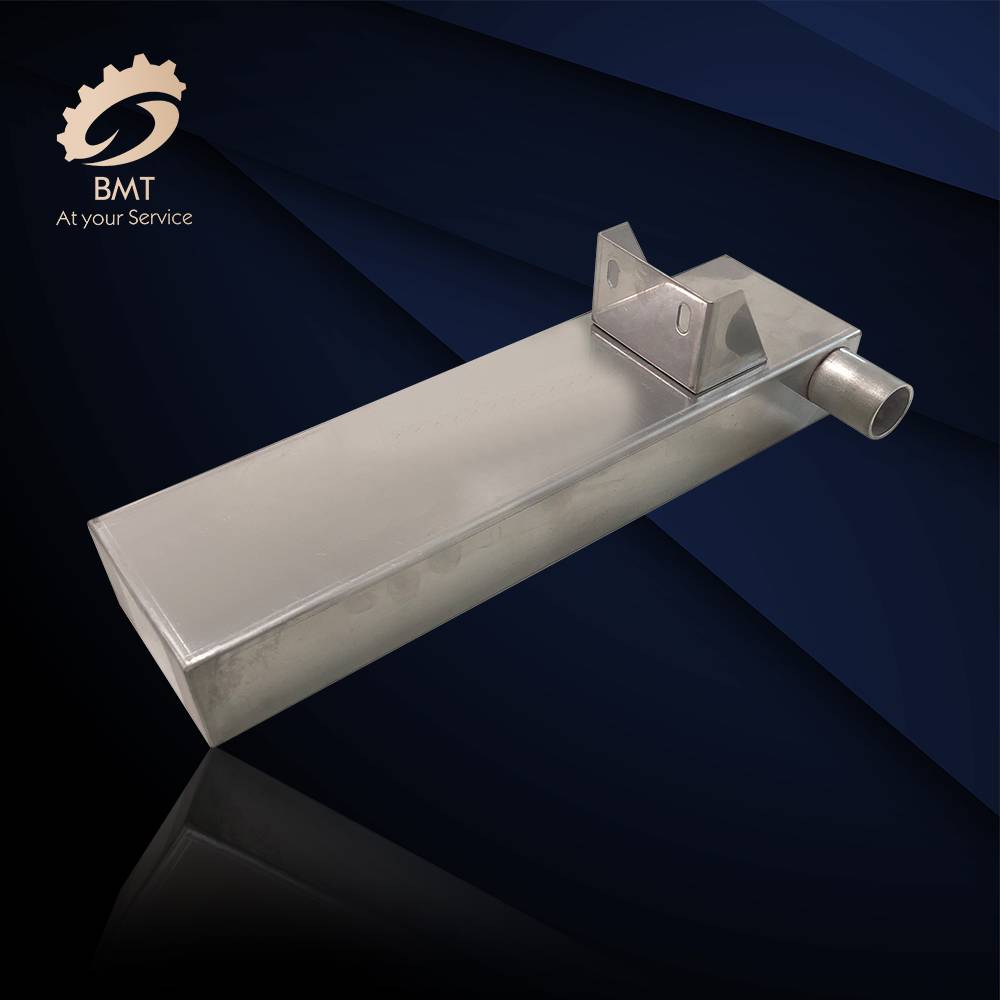

Factory wholesale Motor Stator Rotor Die - Sheet Metal Fabrication Services – Basile Detail:

Bending Importance of Sheet Metal Works

Although the sheet metal bending seems extremely simple, it hides a series of rules and technology that allows you to realize simple or extremely complex shapes. The sheet metal bending is one of the most common processes in manufacturing industry.

Similar to the forming process, the bending works create a change of direction in sheet metal. For example, transform a flat sheet metal into an angular sheet. In fact, through the use of a CNC press, a mold, bending machine or any other machines, the sheet metal can reach the shape of a corner.

Sheet metal fabrications is a process that allows you to realize simple or extremely complex shapes and which can be applied on a wide range of metals: from iron to copper, from brass to aluminum, from stainless steel to other special alloys.

When you need to decide the kind of bending, you must take into account: the thickness of the metal, the type of curve, the angle of bend, and workpiece dimensions and other related important factors.

A general rule about this could be: the larger is the bending, the less acute degree between upper and lower mold. Concerning issues that we have just mentioned, you can choose different types of bending.

There are many factors that can affect the result of sheet metal bending. For example, the most important are:

1.The metal properties

2.The stress caused from the previous process

3.The kind of the edges you want to realize

4.The length and the thickness of the work piece

5.The processing temperature

There are a lot of advantages of Sheet Metal Fabrication, including material selection (Aluminum, Copper, Stainless Steel and others), finishing selection (Bead Blasting, Anodizing, Plating, Powder Coating, etc.), thickness selection (Based on gauges), durability, scalability, quick turnaround, etc. For more details, please see below chart.

|

NO |

ITEMS |

DETAILS |

|

1 |

Material |

Aluminum, Steel, Brass, Copper, Stainless steel, Plastic, POM, Derlin, Titanium Alloy, etc. |

|

2 |

Surface Treatment |

Zinc plating, Anodization, Chemical film, Powder coating, Passivation, Sand blasting, Brushing & polishing, etc. |

|

3 |

Processing Equipment |

Cnc Machining Center, CNC Lathe, Grinding Machine, Automatic Lathe Machine, Lathe Machine, Milling Machine, EDM, etc. |

|

4 |

Inspection Equipment |

3D CMM; 2.5D images measuring instrument, Roughness meter, slide caliper, micrometers, gauge block, dial indicator, thread gauge, universal angle rule, etc. |

|

5 |

Our Services |

CNC Machining, Milling, Turning, Grinding, Stamping, Punching, and assembly, etc. |

|

6 |

QC System |

100% inspection before shipment, Third Party inspection available upon request. |

|

7 |

Packing |

Foam, Carton, Wooden boxes, as customized requirements. |

|

8 |

Payment Terms |

30% T/T in advance, 70% balance before shipment. |

|

9 |

Product Scope |

CNC machining/turning parts, Jig & Fixture Design and Make, Sheet Metal Parts and Stamping Parts. |

|

10 |

Application |

Automation machine, industrial machine, electric appliance, Auto Parts, Furniture Parts, Machinery Parts, Light fittings, etc. |

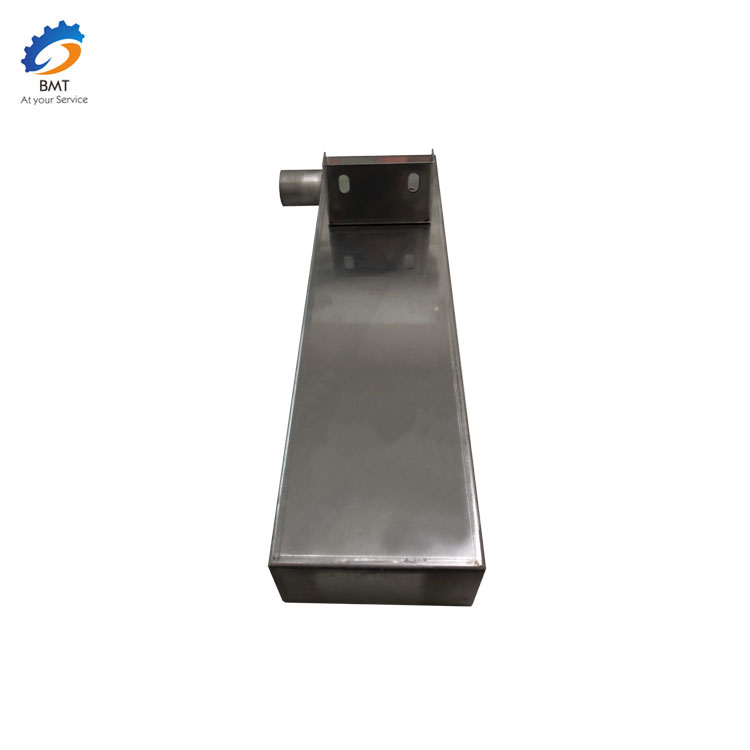

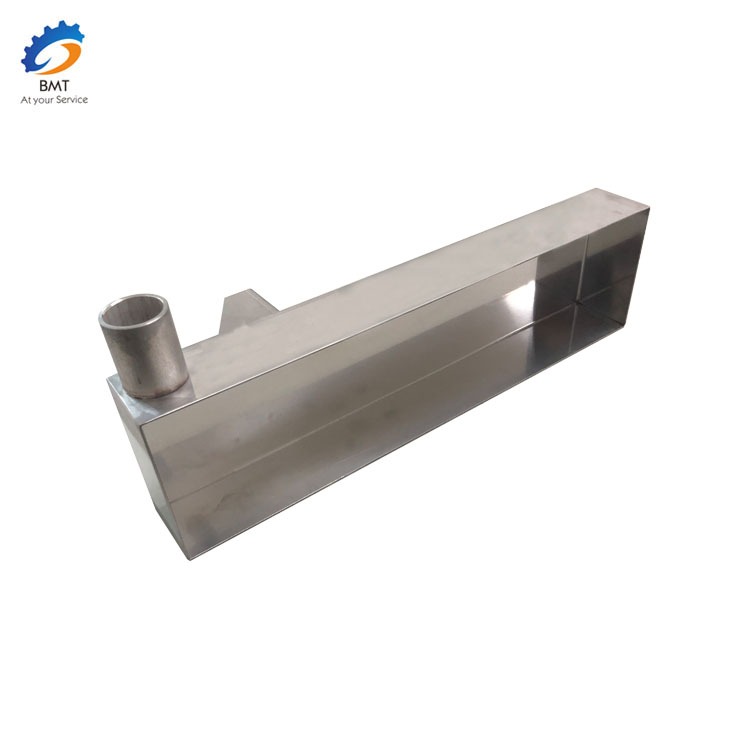

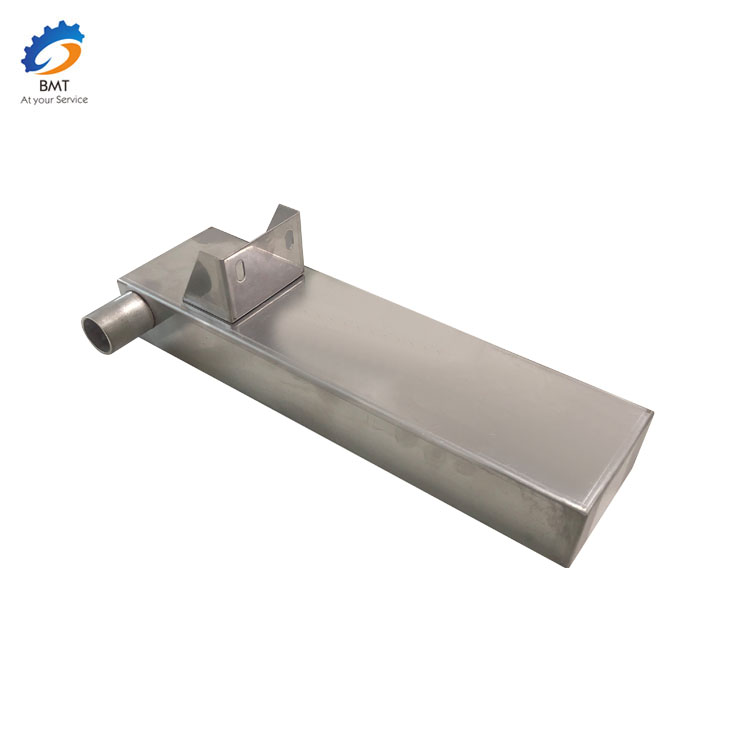

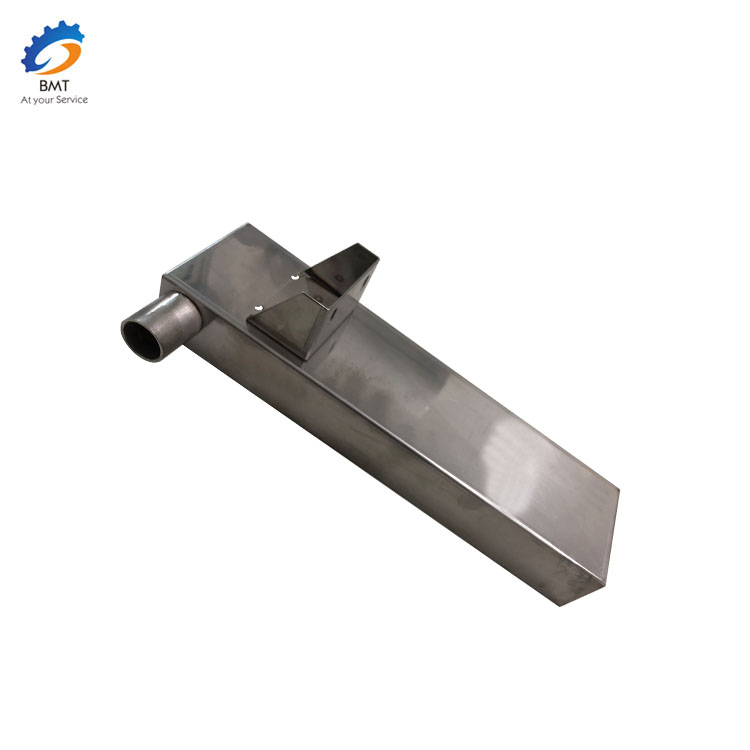

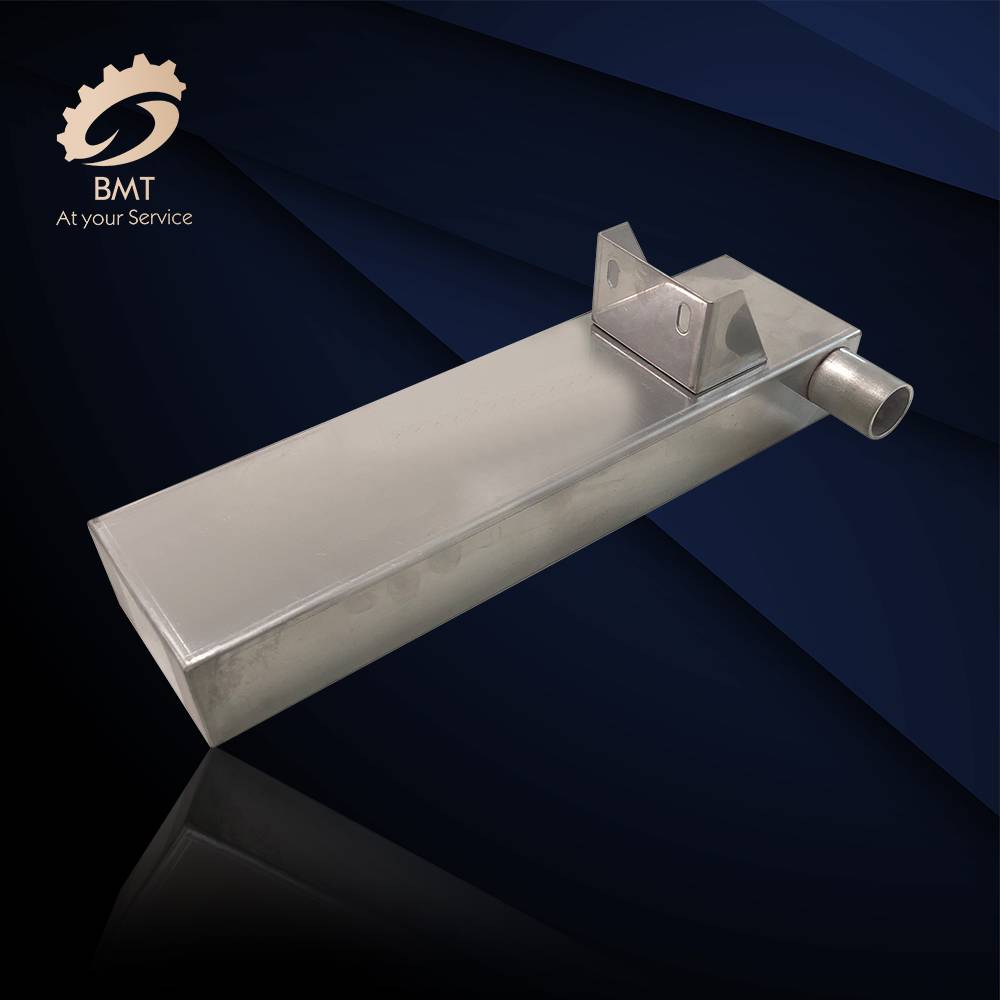

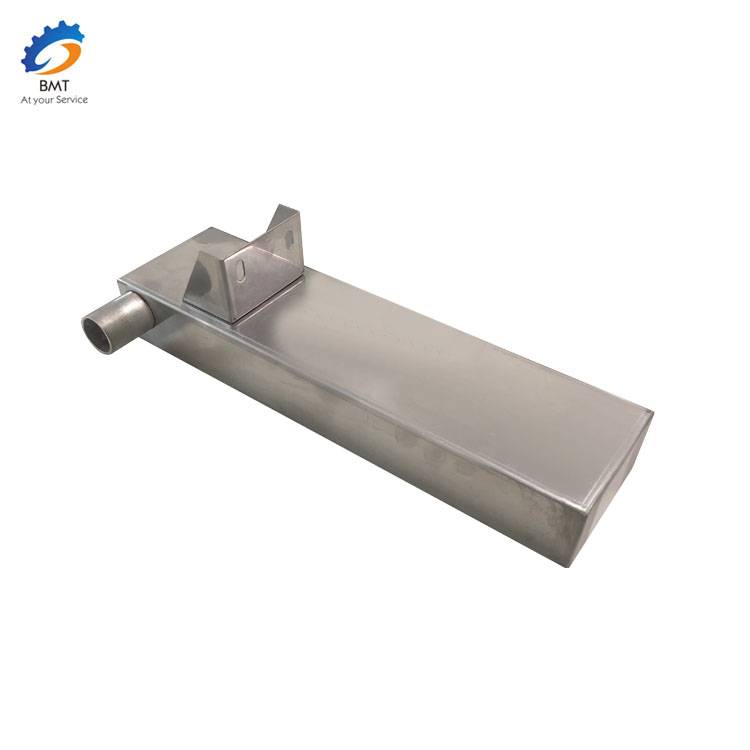

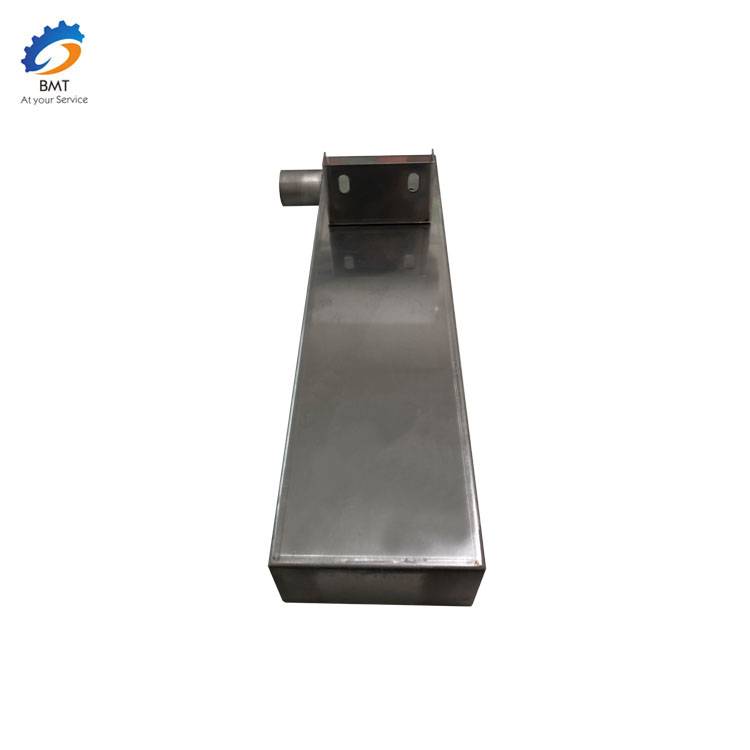

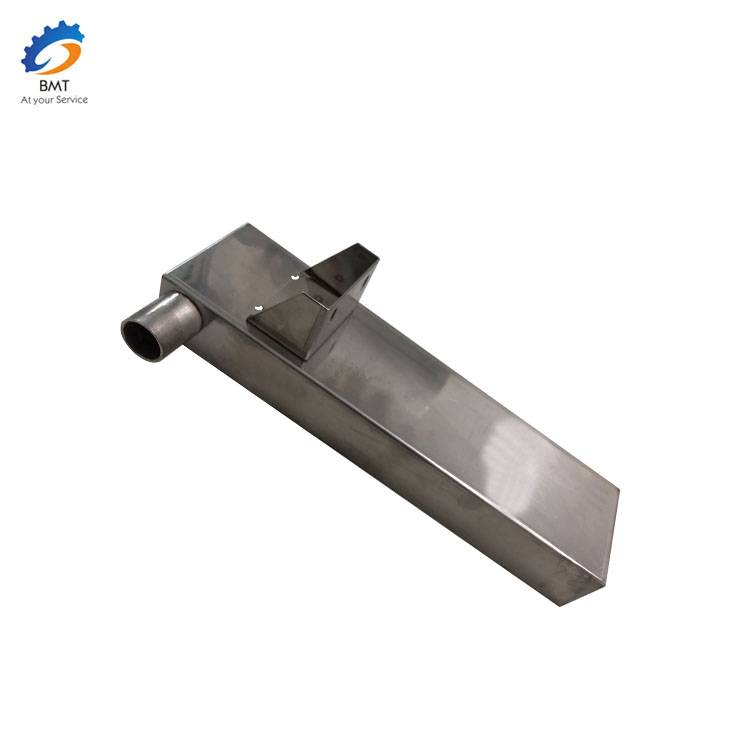

Product Description

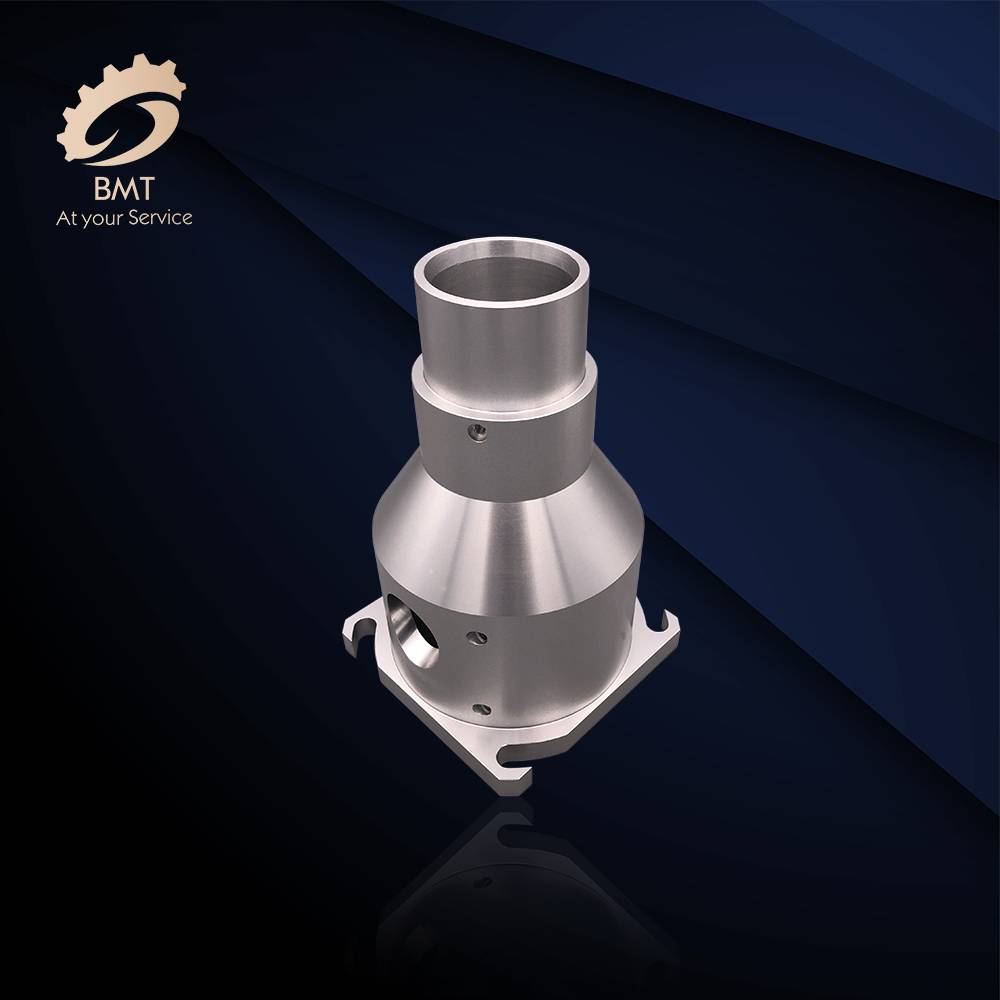

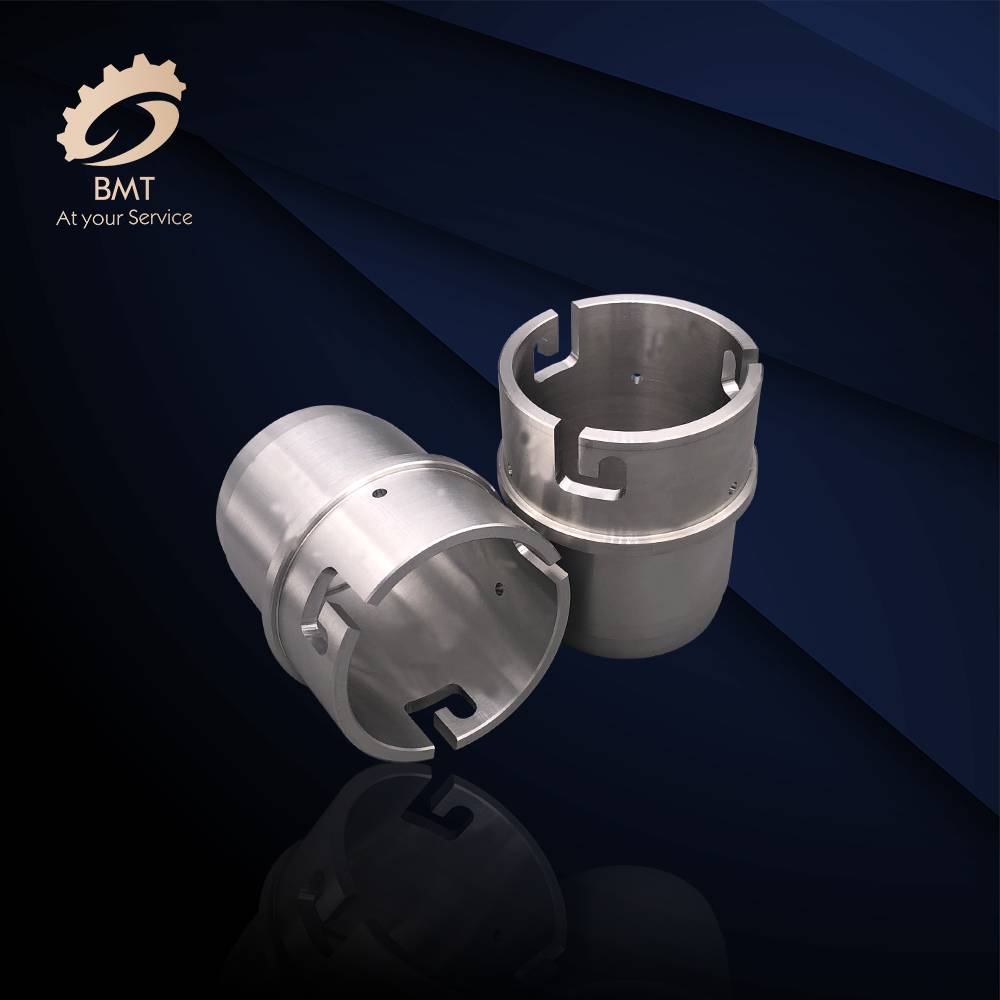

Precision Machining Parts

Precision Machining Parts

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory wholesale Motor Stator Rotor Die - Sheet Metal Fabrication Services – Basile, The product will supply to all over the world, such as: Jakarta, Argentina, Buenos Aires, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

Send your message to us:

-

Cheapest Factory Stainless Steel Sheet Metal Fa...

-

Factory wholesale Cnc Parts And Services Inc -...

-

OEM Factory for Top Cnc Machining Manufacturer ...

-

Online Exporter China Cnc Manufacturing - Prof...

-

2021 wholesale price Ss Sheet Metal Fabricatio...

-

OEM/ODM China Precision Cnc Parts - What are t...