Good Quality High Precision Machine Shop - Titanium Alloy CNC Machining Processing – Basile Detail:

Titanium Alloy CNC Machining

When the hardness of titanium alloy is greater than HB350, cutting is particularly difficult, and when it is less than HB300, it is easy to stick to the knife and it is difficult to cut. Therefore, the titanium processing problem can be solved from the blade. The wear of the insert groove in the machining of titanium alloys is the local wear of the back and front in the direction of the depth of cut, which is often caused by the hardened layer left by the previous machining.

The chemical reaction and diffusion of the tool and the workpiece material at a processing temperature of more than 800 °C are also one of the reasons for the formation of groove wear. Because during the machining process, the titanium molecules of the workpiece accumulate in the front of the blade and are “welded” to the blade edge under high pressure and high temperature, forming a built-up edge.

When the built-up edge peels off the cutting edge, it takes away the carbide coating of the insert, so titanium machining requires special insert materials and geometries.

.

It is worth mentioning that since titanium alloys generate high heat during processing, a large amount of high-pressure cutting fluid must be sprayed on the cutting edge in a timely and accurate manner to quickly remove the heat. There are also unique structures of milling cutters specially used for titanium alloy processing on the market today, which are better suited for titanium alloy processing.

At present, all countries are developing new titanium alloys with low cost and high performance, and strive to make titanium alloys enter the civilian industrial field with huge market potential. my country also spares no effort to move forward in this field.

It is believed that through the joint efforts of all industry professionals, the processing of titanium alloys will no longer be a problem in the future, but will become a sharp blade for the development of my country’s manufacturing industry, overcoming obstacles for the development of the entire industry.

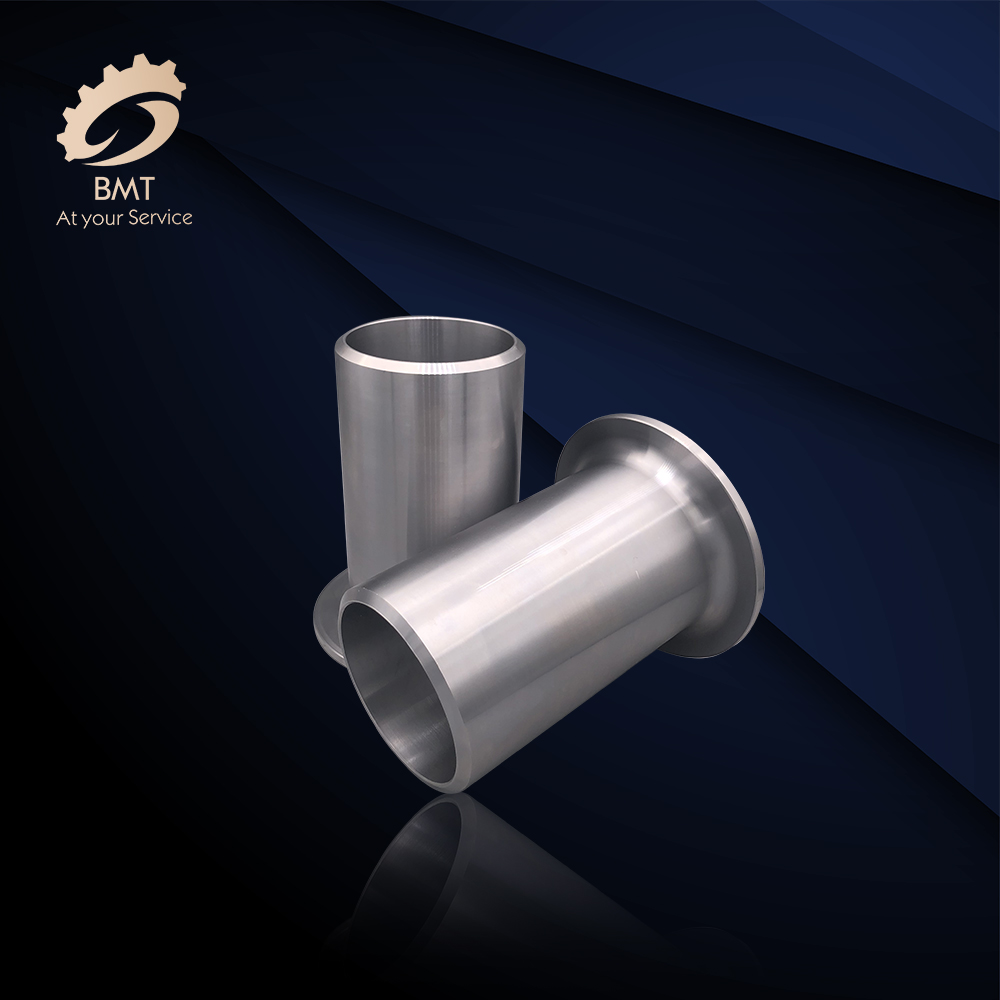

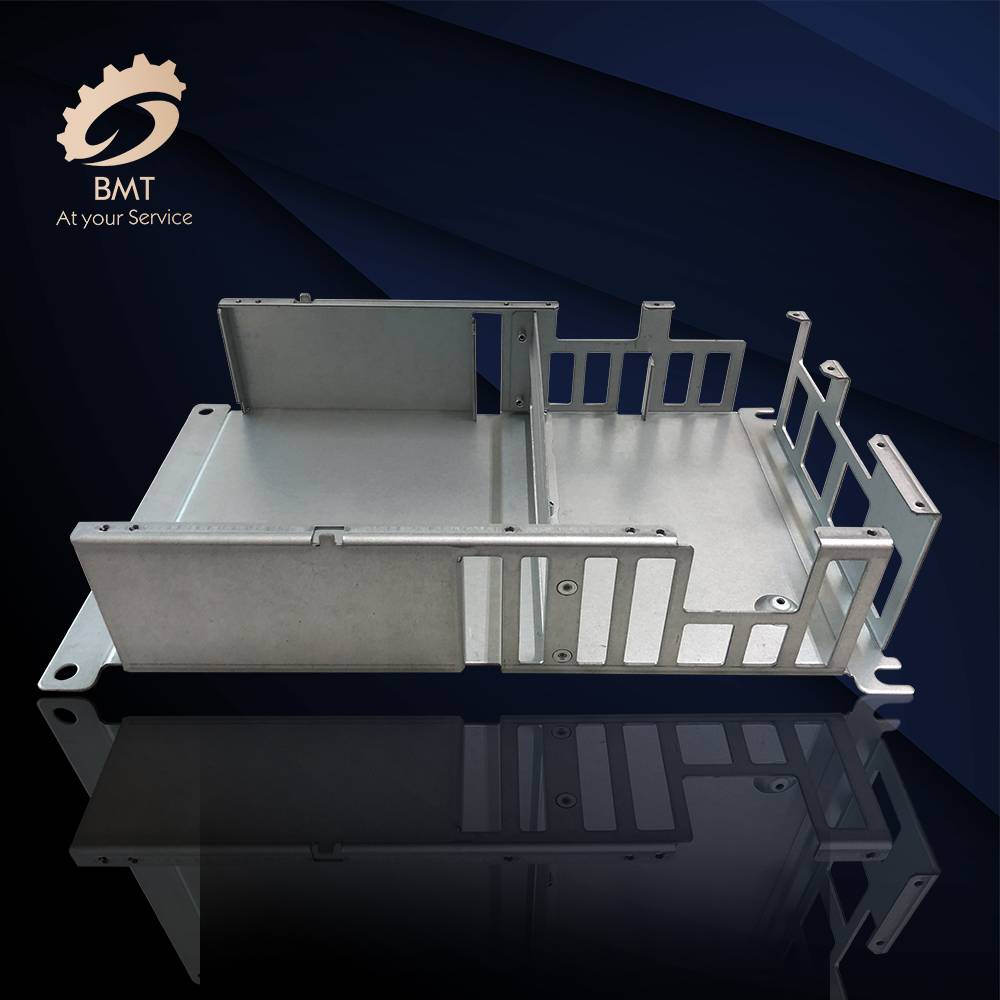

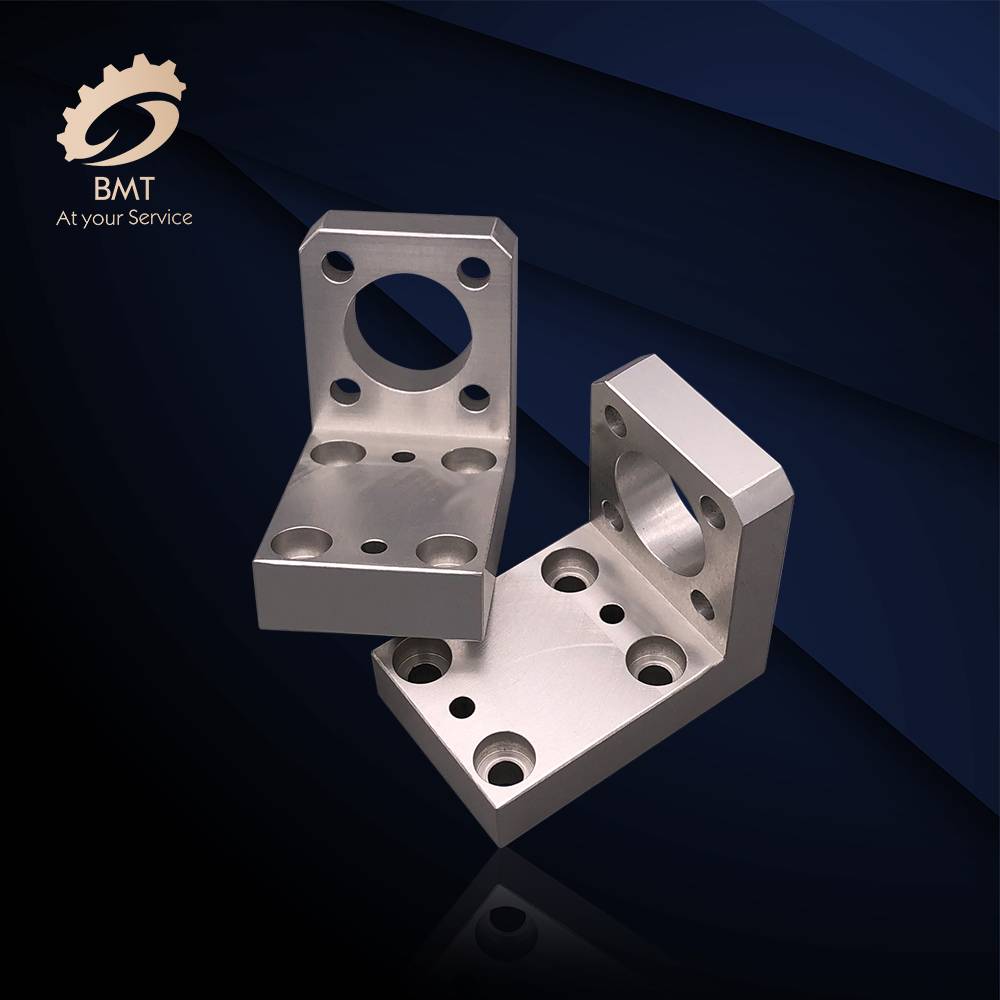

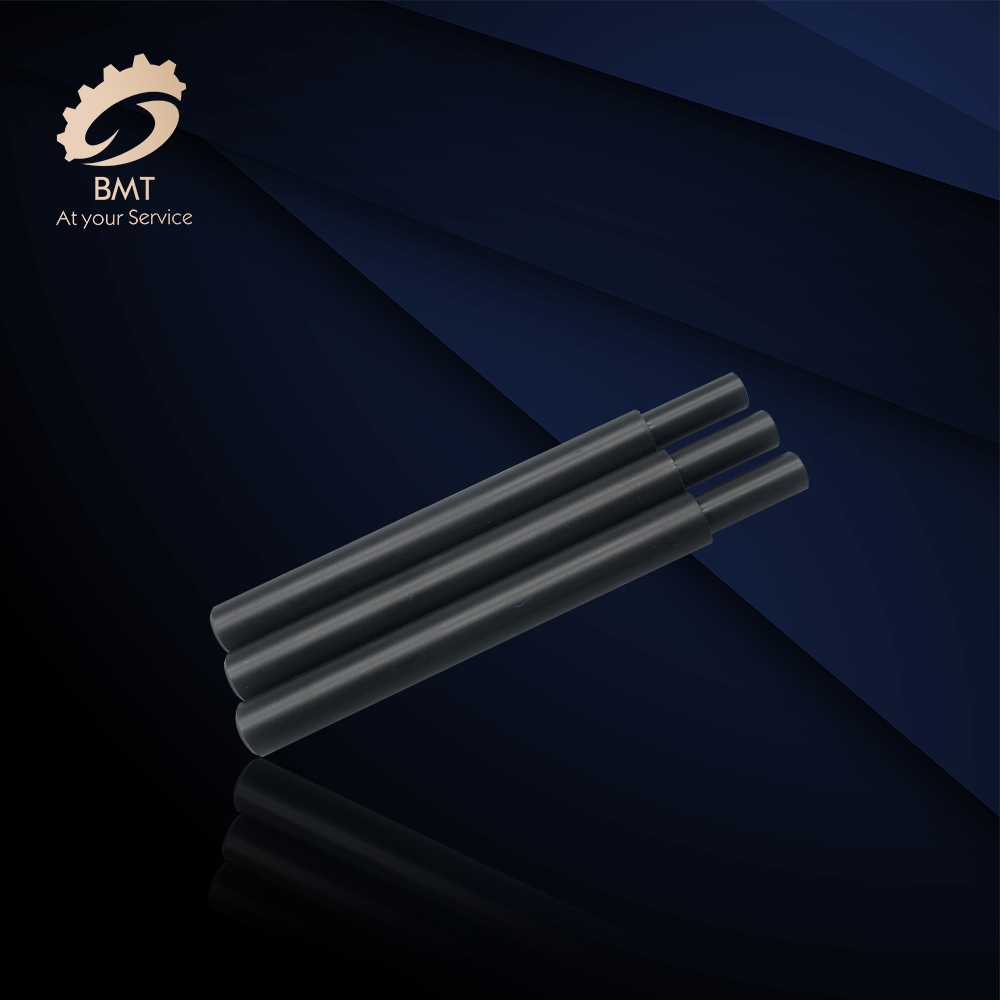

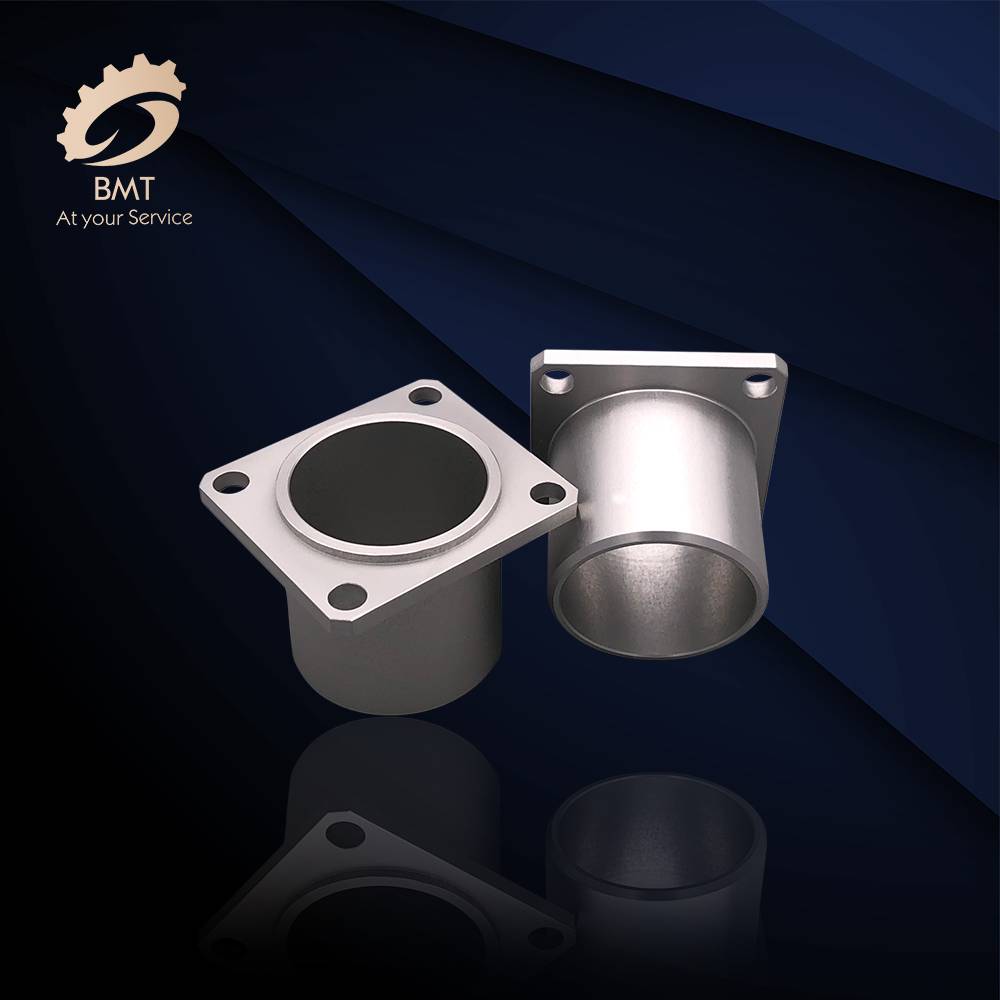

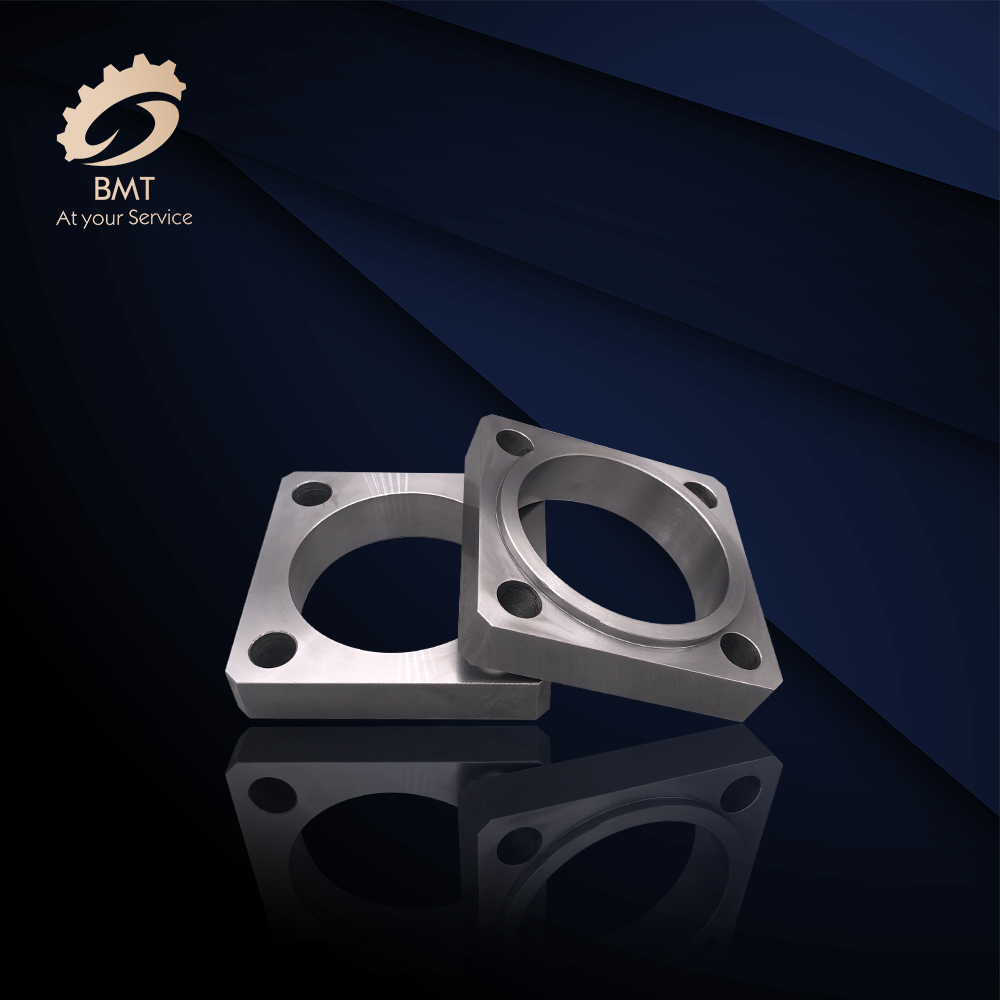

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Good Quality High Precision Machine Shop - Titanium Alloy CNC Machining Processing – Basile, The product will supply to all over the world, such as: Uruguay, Swansea, Bangladesh, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Send your message to us:

-

Chinese wholesale Cnc Bending Machine For Sheet...

-

Factory directly Cnc Turned Parts Manufacturer ...

-

Manufactur standard Cnc Manufacturing Companies...

-

factory Outlets for Cnc Spare Parts - Auto Par...

-

factory Outlets for Cnc Spare Parts - CNC Mach...

-

China Gold Supplier for Small Batch Cnc Machini...