Guiderail Error

Guide also is one of the machine tool error, error in machine tool, the guide rail is mainly responsible for determine the relative position of the machine tool parts, and precision of the slideway, once appear problem, so the location of the parts in machine tool error will occur and the machining accuracy will therefore be affected. In general, guide error mainly the existence of the parallel degree of distortion, saddle, drum error, horizontal parallel straightness error, straightness error of several ways, such as the parallel distortion refers to the front and rear guide rail from parallel state; Saddle error is backward protruding guide rail, guide rail is protruding drum error, both is a kind of guide rail shape change; And straight and level and vertical straightness error is the guide rail vertical bending, lateral bending.

The Transmission Chain Error

Transmission chain of the main function is to control the rotation of the workpiece and tool, in which there are many moving parts, if these components appear error during manufacturing, assembly, or in the process of using the serious wear and tear, so the ratio relationship between the tool and workpiece will be affected, and thus affect the machining accuracy.

Stress Deformation

In the process of machining, the machining system will be all kinds of force, such as the centrifugal force, cutting force and so on, these force in driving tool, workpiece, jigs and other complete processing operations, at the same time, will also affect other components location, movement speed, which results in the decrease of the machining accuracy. For example, when cutting tool in machining process is affected by the centrifugal force, the original cutting vibration will occur and operation and artifacts caused by high speed vibration and the cutting face of mechanical parts will appear error.

Machine Tool, Cutting Tool Thermal Deformation

Mechanical parts production processing system of the various components of high speed games makes a high-speed friction between parts or components with air, and then produce a lot of heat, and under the influence of heat bilges cold shrink phenomenon, machining system will appear different degrees of thermal deformation and, in turn, affect the machining accuracy, the phenomenon in the machine tool, cutting tool, Workpieces are very common, when there is the thermal deformation of machine tool, the spindle box and the guide rail is likely to appear deformation, bending, leading to guide error and the error of spindle.

And when there is hot deformation tool, its volume will be continued volatility in a certain range, and processing of mechanical parts size of different sizes would happen. In addition, the thermal deformation of the workpiece will affect the volume of a workpiece, although a change that will not directly affect the shape, but if the workpiece is heated unevenly, so it in the process of deformation also can cause internal stress from the inside, and the internal stress will be as the surface of metal workpiece excision and internal redistribution in artifacts, prompting the artifacts appear obvious deformation, and after the workpiece deformation , machinery parts processing precision nature also decreases.

Send your message to us:

-

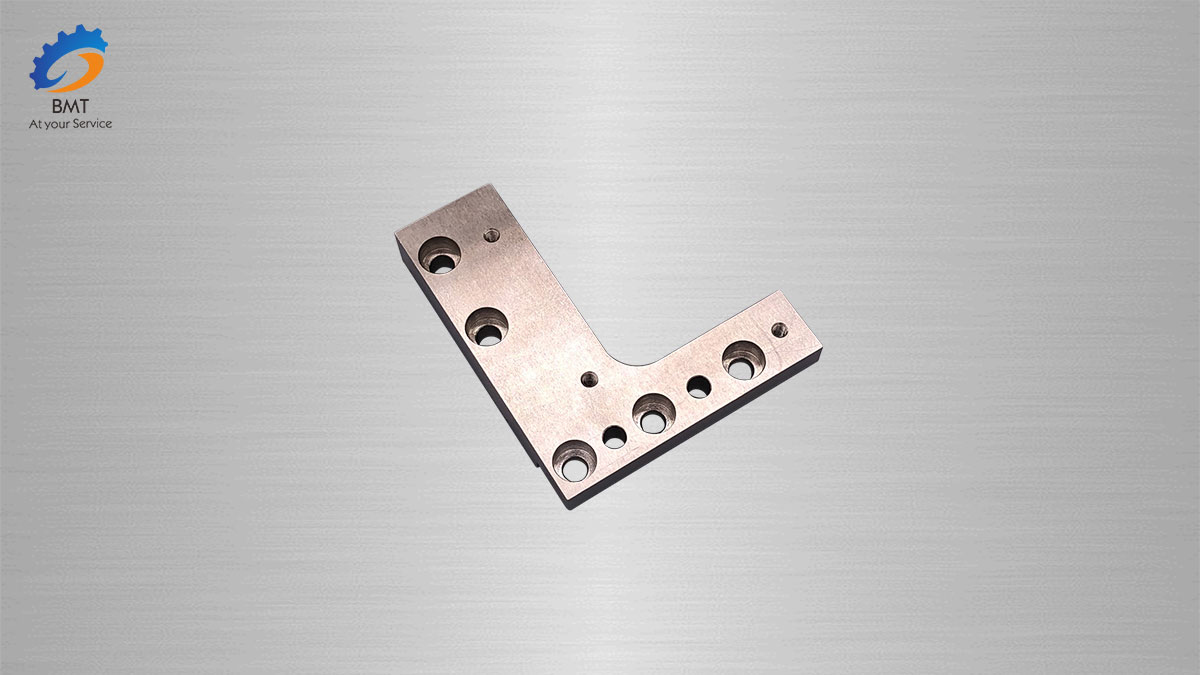

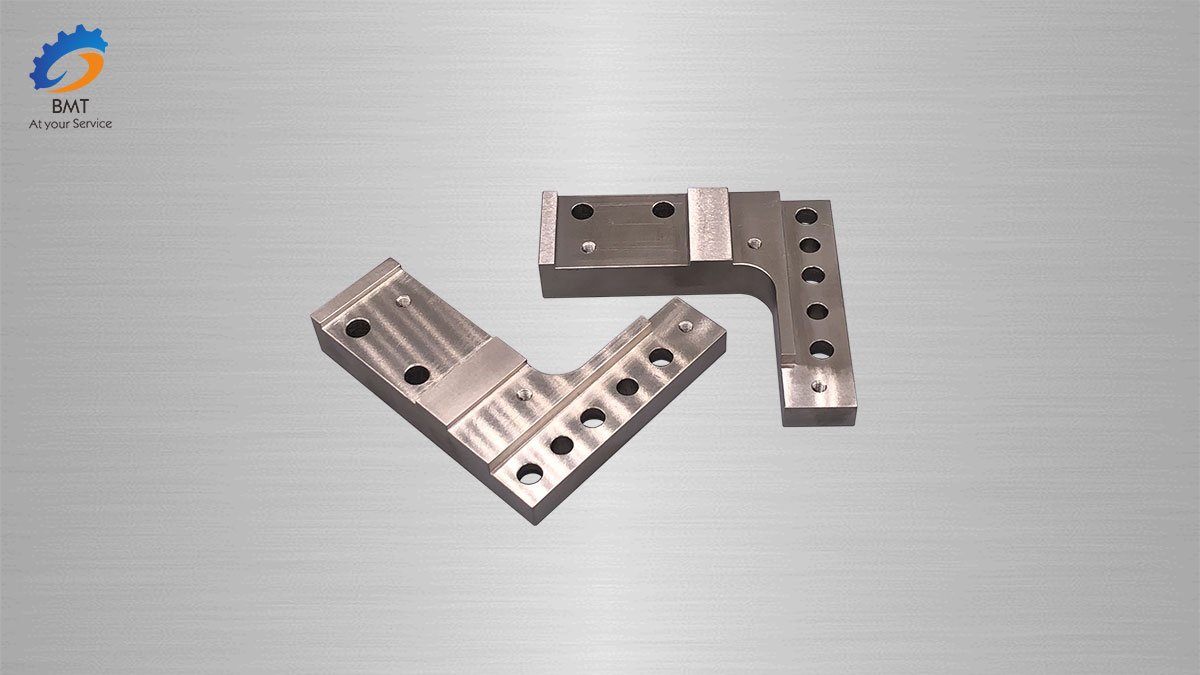

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes