Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for High Quality China High Precision Aluminum Alloy CNC Machining Factory, Our company eagerly looks forward to creating long-term and welcoming company partner associations with purchasers and businessmen from everywhere in the entire world.

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for China CNC Machining, Steel Parts, we’re now looking forward to even greater cooperation with overseas customers based on mutual benefits. We’ll work wholeheartedly to improve our merchandise and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Product Description

Precision machining can bring any manufacturing process to the next level. It can work wonders for operational efficiency, minimize turnaround time, and cut production cost. Who knows this better than one of China’s major CNC Turning and Milling components manufacturers with 15 years of experience under its belt? BMT has been providing exceptional precision parts for industries ever since.

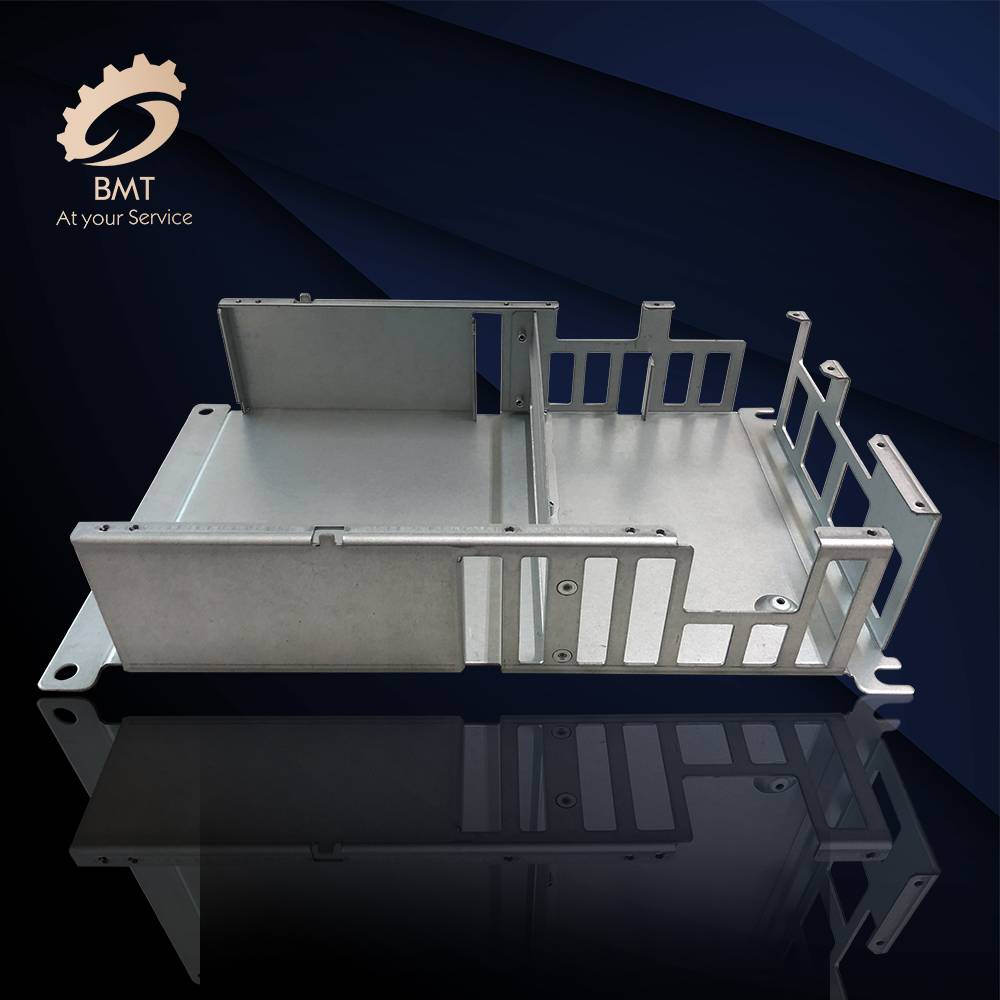

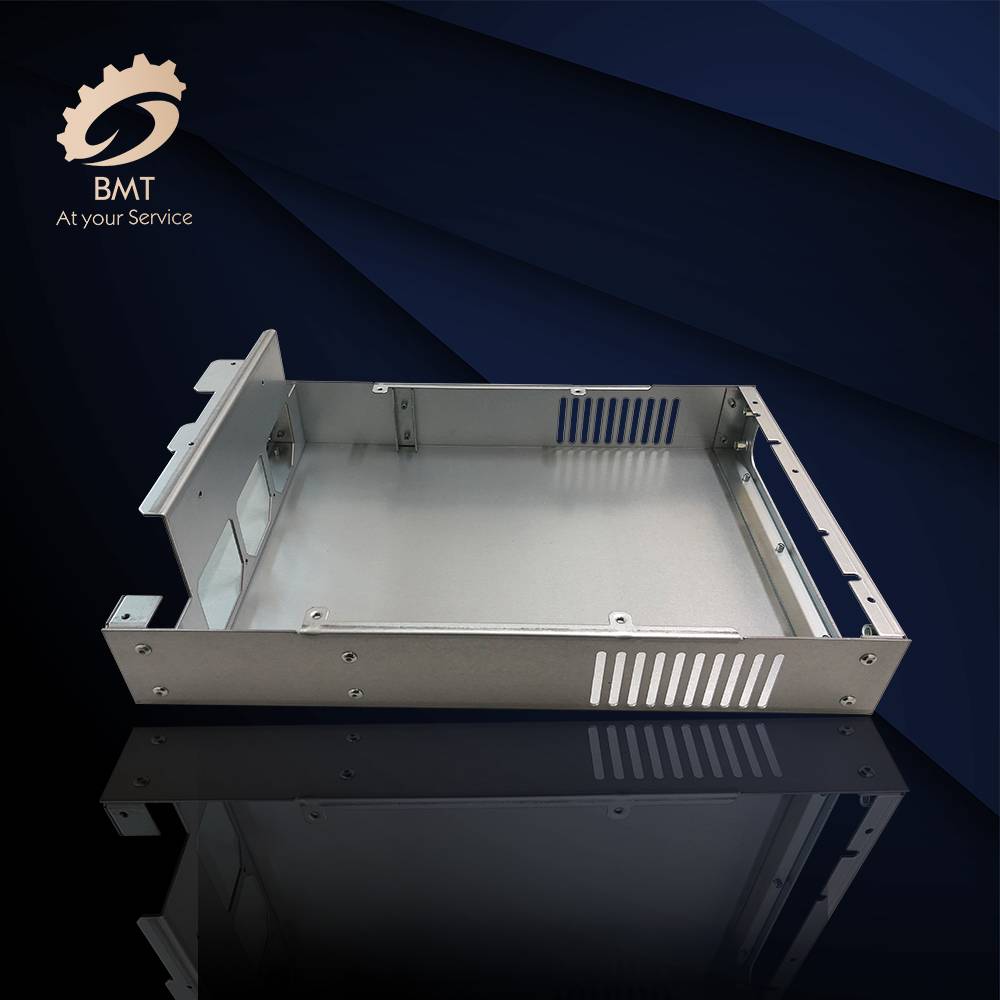

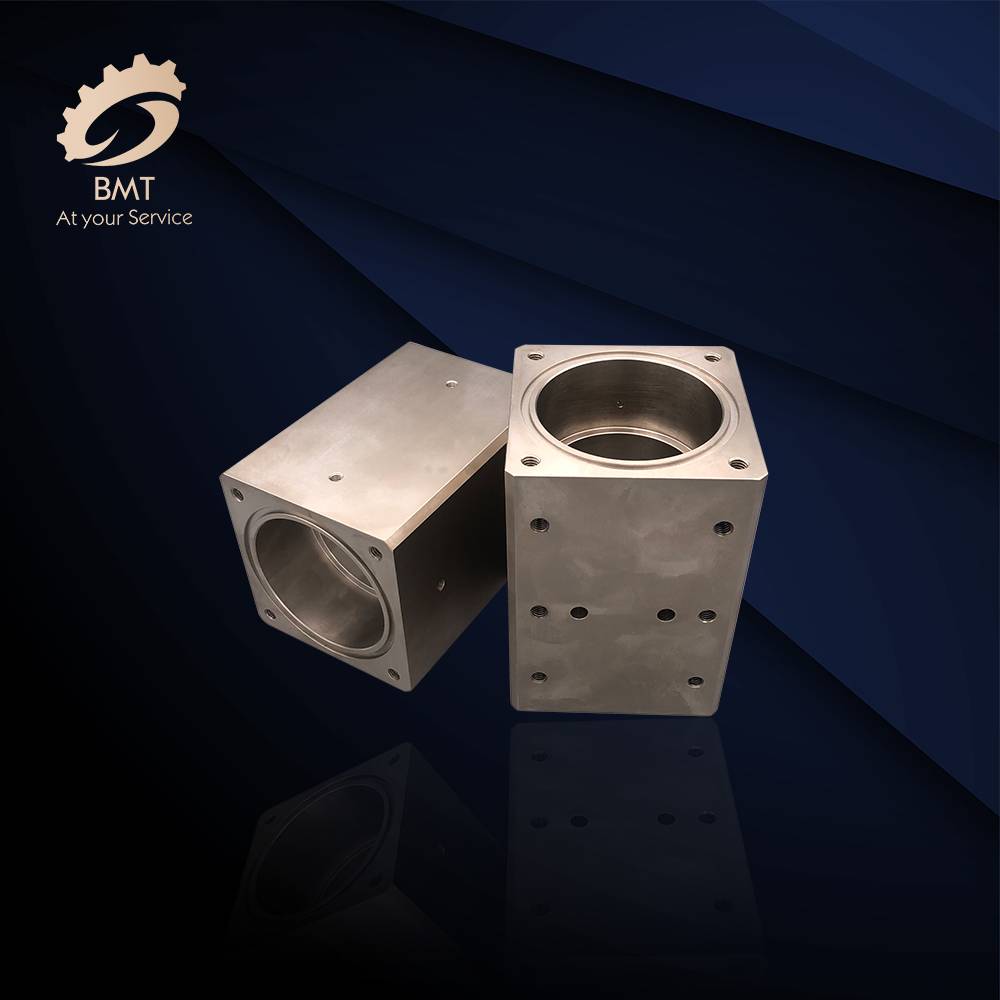

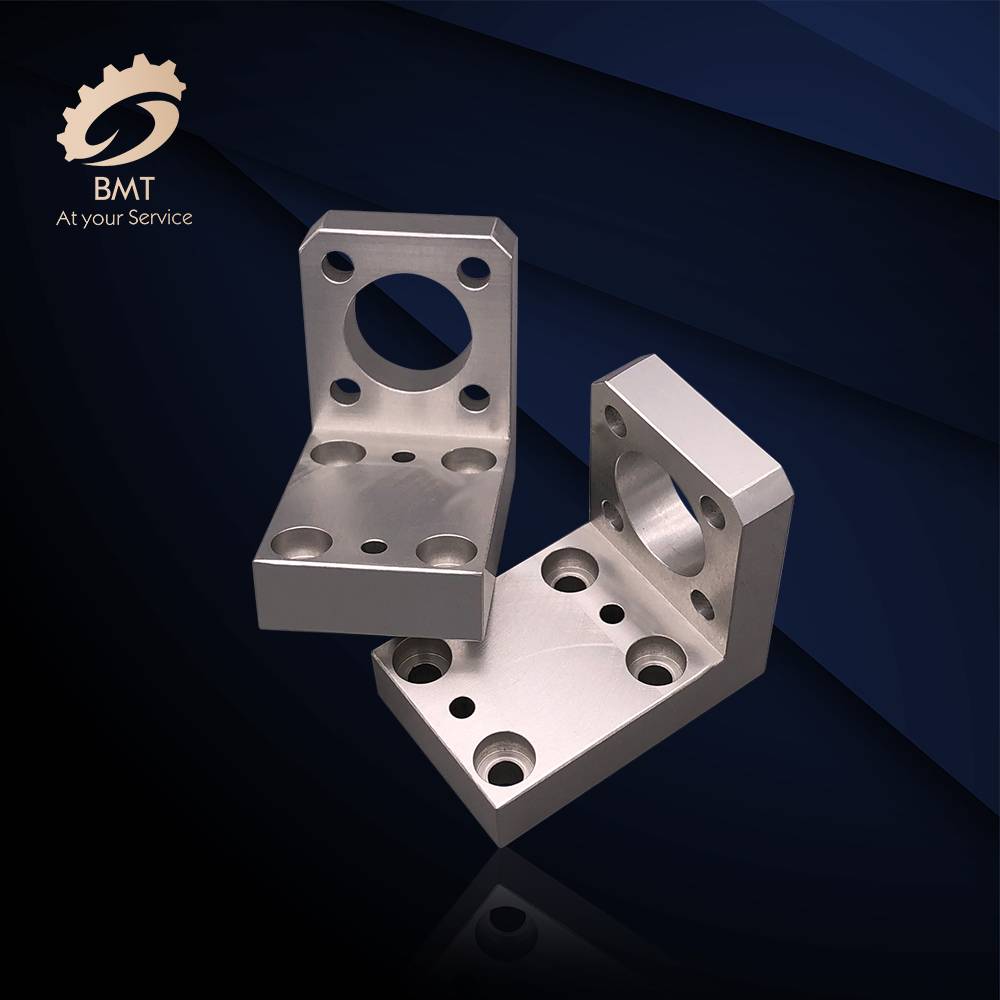

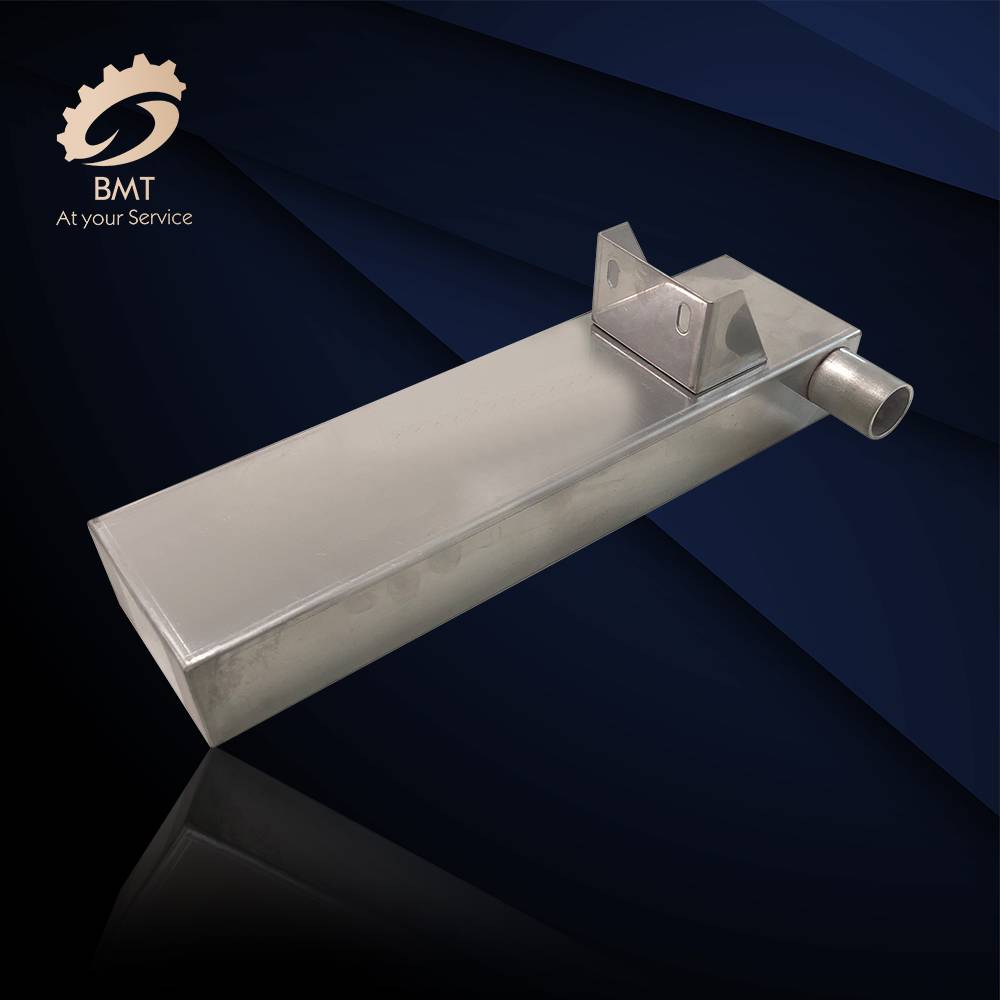

Our CNC manufacturing capabilities are backed up by state-of-the-art equipment, including 3-axis and 4-axis machines, conventional lathes, bandsaw cutting machines, milling tools, laser engravers, radial drilling machine, WEDM, etc. What does that mean to you? BMT has everything it takes to supply you with whatever precision items you need – from milling and turning components to automatic machining and sheet metal and stamping ones.

Product Description

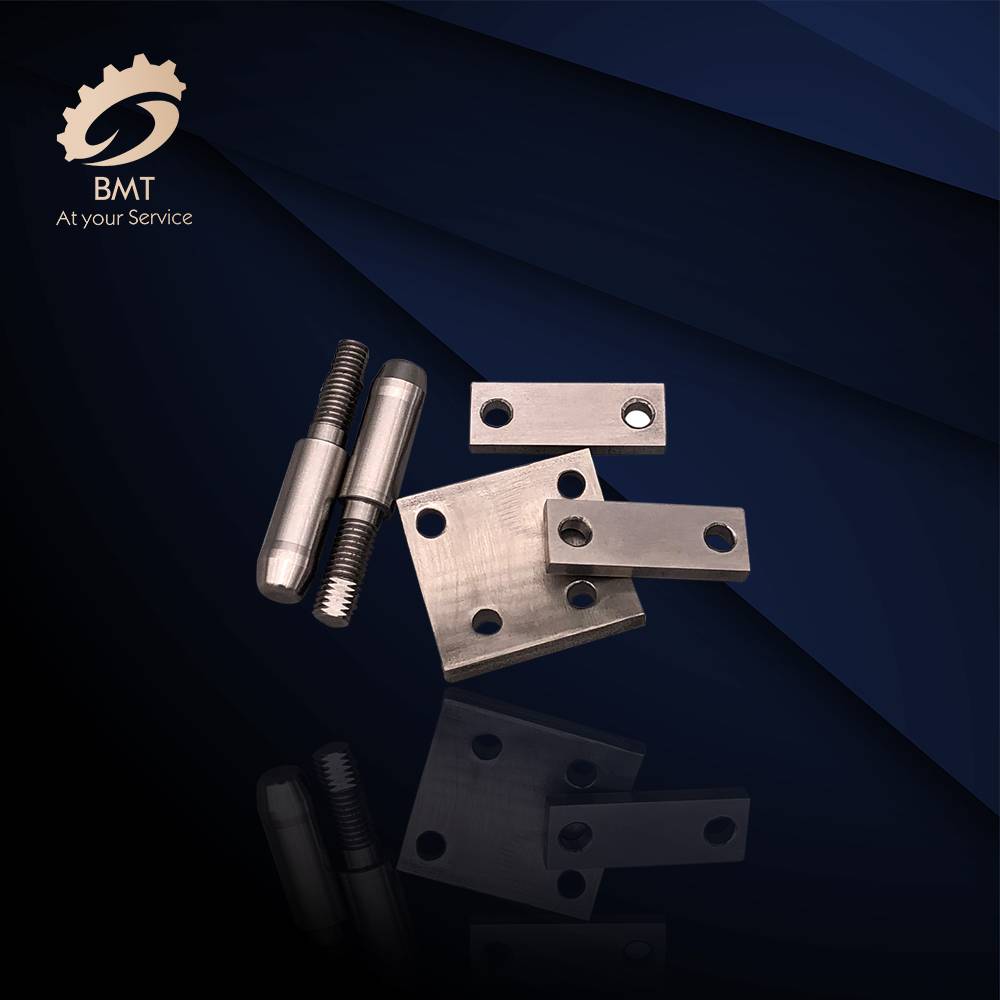

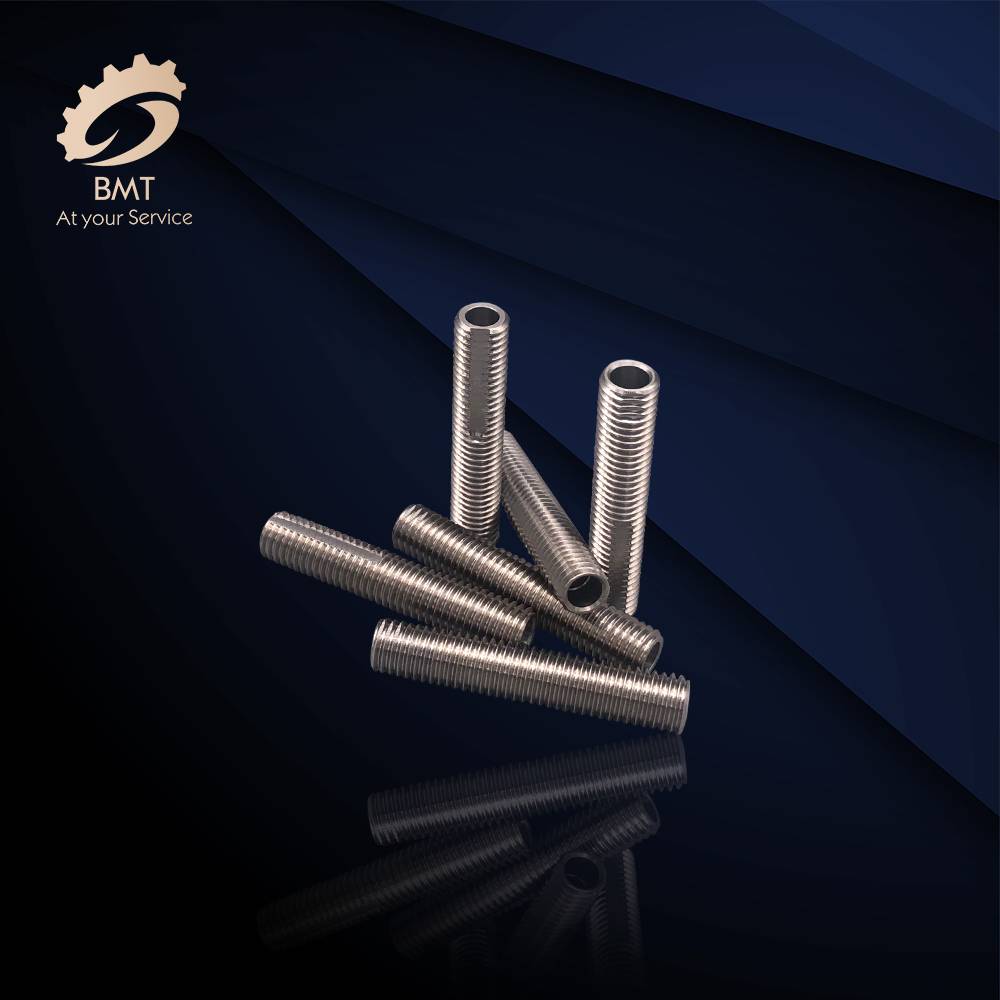

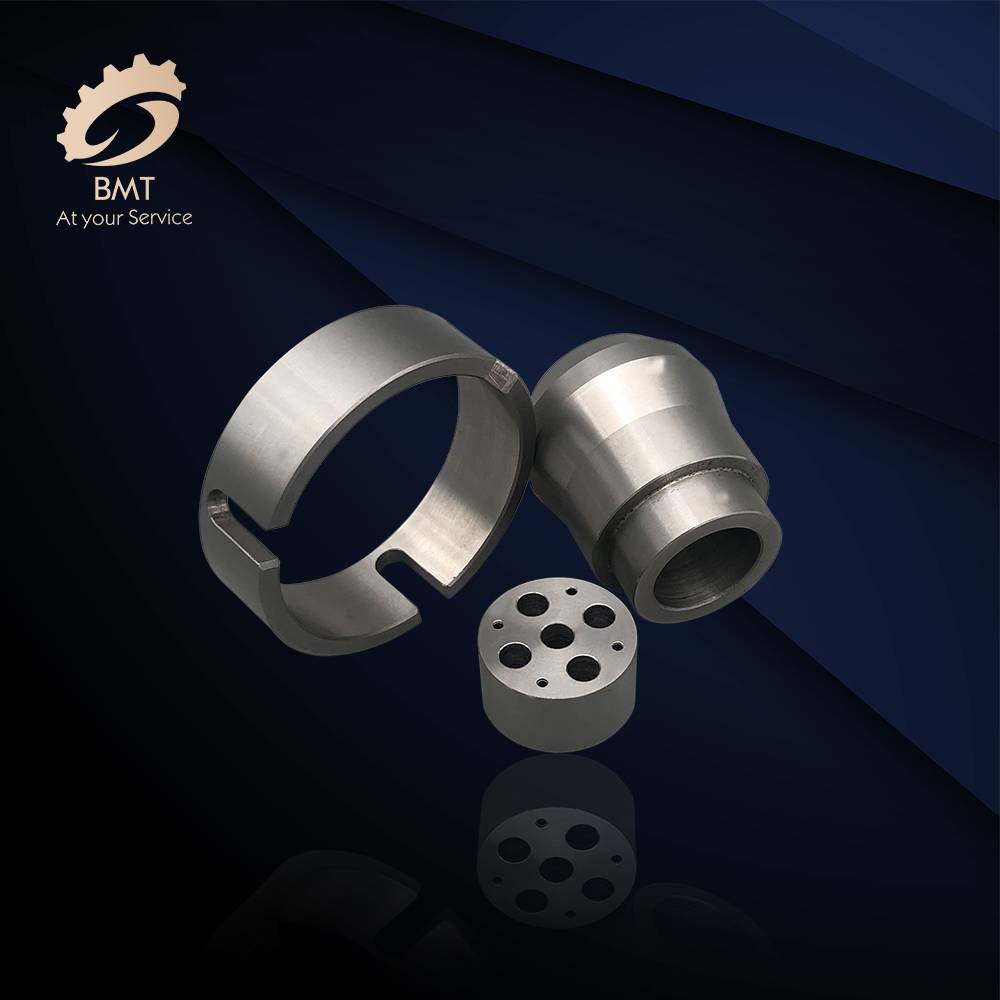

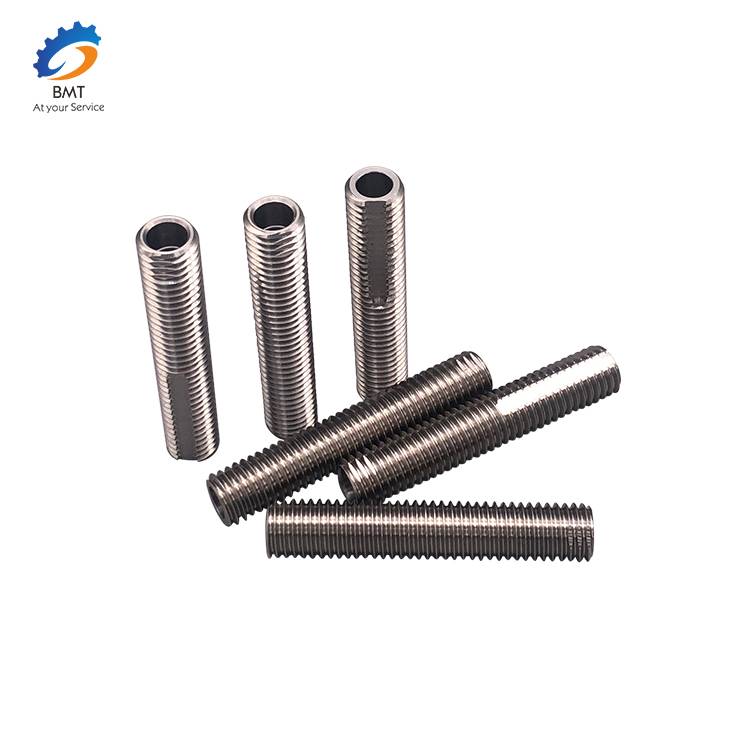

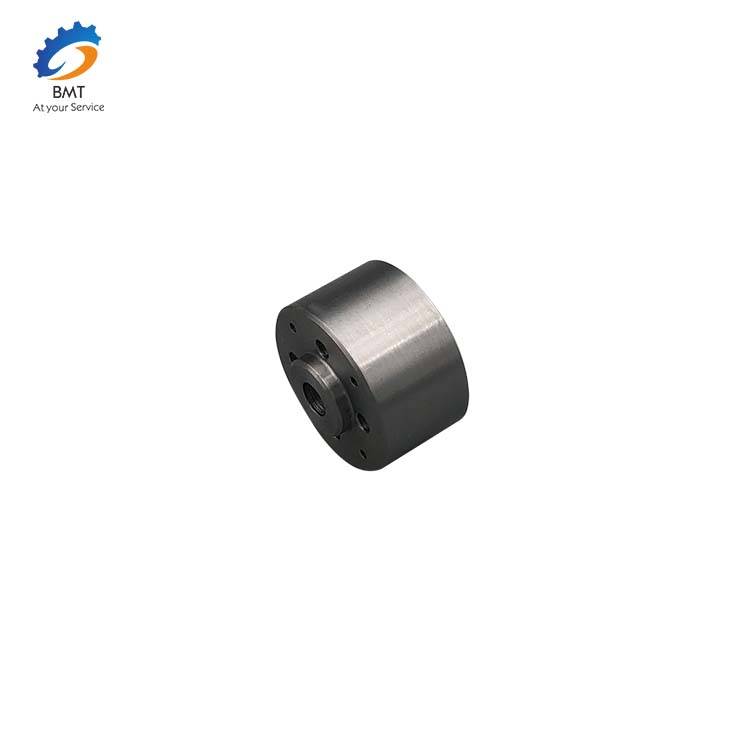

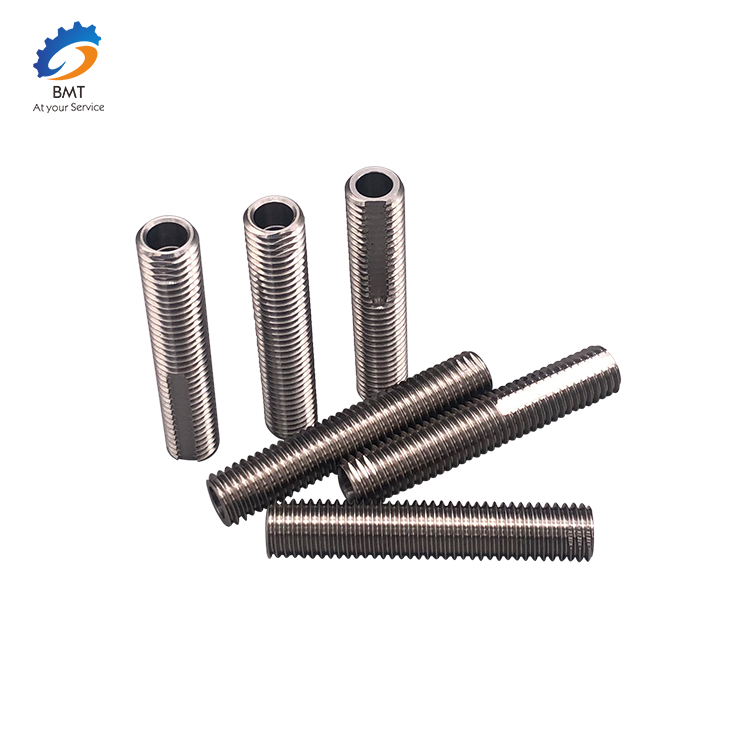

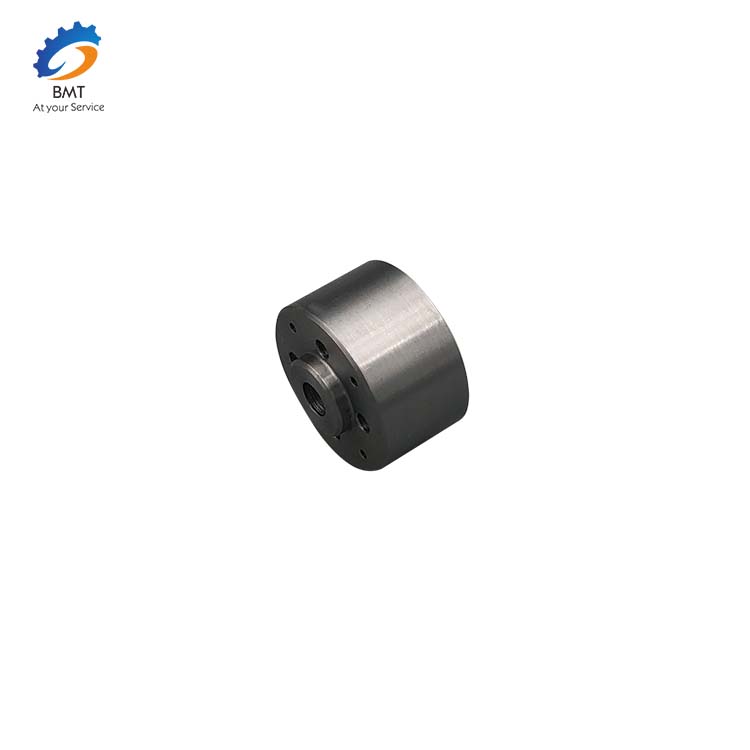

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Why Choose Our CNC Machined Parts?

With us, you can benefit from much more than just a varied assortment of precision items. As one of the top CNC machining parts suppliers, we are in a position to provide you with professional related to:

Quality

Our products can be designed to comply with ROHS, REACH, ASTM, ISO, and other international standards.

Durability

All of our CNC parts undergo a range of control procedures to ensure that they can withstand regular use. With us, you can take advantage of precision machining while saving a lot.

Service

Do you need help with installing some components or want to order custom machined parts? Contact us at your convenience.

Although our main production facility is based in Dalian, China, we supply CNC machining parts outside China, too. The coverage of BMT extends far beyond local markets, and we’ve successfully made a name for ourselves in the USA, Germany, Italy, Saudi Arabic and Russia. The world’s leading manufacturer trust us as we always meet their needs.

If you’re engaged in one of these or any other industry that relies on the use of CNC technologies, rest assured that BMT can help you take your production up a notch. We work with a variety of materials, including stainless steel, aluminum, titanium, bronze, brass, etc. Let us know what your manufacturing processes call for, and we’ll supply you with that for a reasonable price.

For your convenience, you can find the much-needed CNC machined parts in a few clicks with the help of a search bar on our website. Feel free to send us emails or call us at any time. BMT—At Your Service!

Types of Erosion Machining Technologies

While burning tools apply heat to melt excess stock, erosion machining devices use water or electricity to erode material off the workpiece. The two main types of erosion machining technologies are:

Water jet cutting: This process uses a high-pressurized stream of water to cut through material. Abrasive powder may be added to the water stream to facilitate erosion. Water jet cutting is typically used on materials that can suffer damage or deformation from a heat affected zone.

Electric discharge machining (EDM): Also known as spark machining, this process uses electric arcing discharges to create micro-craters that rapidly result in complete cuts. EDM is used in applications requiring complex geometrical shapes in hard materials and at close tolerances. EDM requires the base material to be electrically conductive, which limits its use to ferrous alloys.

Send your message to us:

-

New Arrival China China CNC Hydraulic Sheet Met...

-

15 Years Exporter China OEM Customized Machine ...

-

High Quality China Cheap Design Sheet Metal Las...

-

factory low price China Factory Directly Supply...

-

China Factory for China ADC12, Dynacast Rexroth...

-

Reasonable price for China Custom Manufacturer ...