High Quality for Lathe Machining Part - Stainless Steel Precision CNC Machining – Basile Detail:

Advantages of CNC Machining

The Advantages of CNC Machining

✔ High Precision, Strict Tolerance;

✔ Good Physical Properties;

✔ Relatively Lower Setup Costs;

✔ Customized Properties;

✔ Quickly Implementation of Machining.

CNC Machining Questions and Answers

Q1: What language is used by CNC machines?

A1: CNC machines are primarily programmed using G-code and M-code, both codes are acceptable.

Q2: Are CNC and VMC the same?

A2: The answer is absolutely NO.

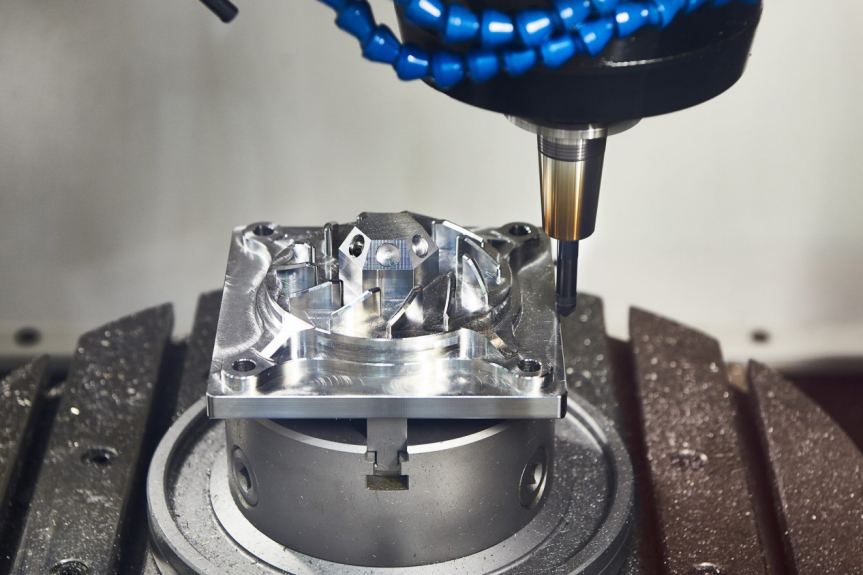

✔ CNC (So called computer numerical control) is the automation of machine instruments through the use of computers which have been programmed to execute any number of commands to produce the custom parts. In a word, a computer controls CNC machines.

✔ VMC (So called Vertical Machining Center) is a kind of machinery which can be employed to do several machining processes, like drilling, and milling functions. A VMC is a kind of CNC machine used to cut metals.

Q3: What is the difference between PLC and CNC?

A3: PLC (Programmable Logic Controller) is sequential, while CNC is conditional.

Q4: Who invented CNC machining and its importance?

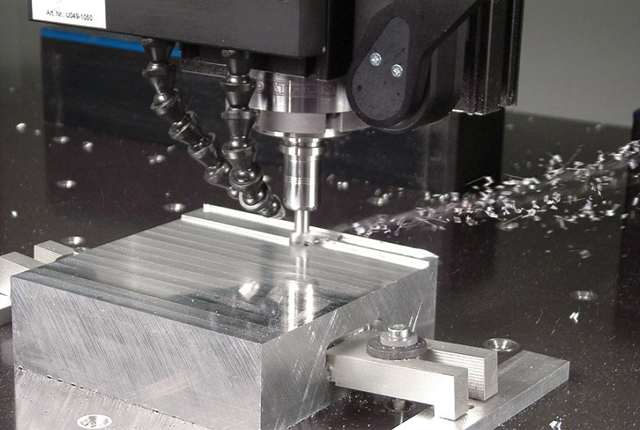

A4: John T. Parsons. CNC Machining is a subtractive process that removes material from a billet using a circular cutting tool, which plays an important role in modern mechanical machining technology.

Q5: What is the significance of CNC machining?

A5: As the process is automated, it increases efficiency, lowers costs and increases accuracy.

Q6: What materials can be used in CNC machining?

A6: Depending on the applications. Normally, the common materials include Stainless Steel, Carbon Steel, Copper, Brass, Aluminum, Titanium, Alloy, Polypropylene, ABS, POM, PC, and Nylon, etc.

Q7: What kinds of CNC machines we have?

A7: Conventional Lathe Machine, CNC Lathe Machine, Milling Machine, Drilling Machine, Laser Cutting Machine, Plasma Cutting Machine, WEDM, Welding Machine, Grinding Machine, etc.

Q8: What is the difference between DNC and CNC?

A8: DNC (So called Direct Numerical Control) is a system uses a mainframe computer to operate multiple machines. DNC refers to the networking of more than one CNC machine.

Q9: What is an NC machine?

A9: Numerical Control (NC) machines receive instructions from a punch card, whereas a CNC machine receives instructions from a computer.

Q10: What industries use CNC machining?

A10: Aerospace, medical device, photonics, defense, electronics, transportation and more.

Q11: What type of finish is produced by CNC machining?

A11: Some CNC machines, such as the CNC mill, may leave visible tool marks. Because of this, an additional step may be required to finish the part, like grinding or polishing.

Q12: What is the standard finishes for CNC parts?

A12: Bead blast, anodized, chemical film, passivation, powder coating, electro polishing, electro nickel plating, zinc plating, silver plating and gold plating, etc.

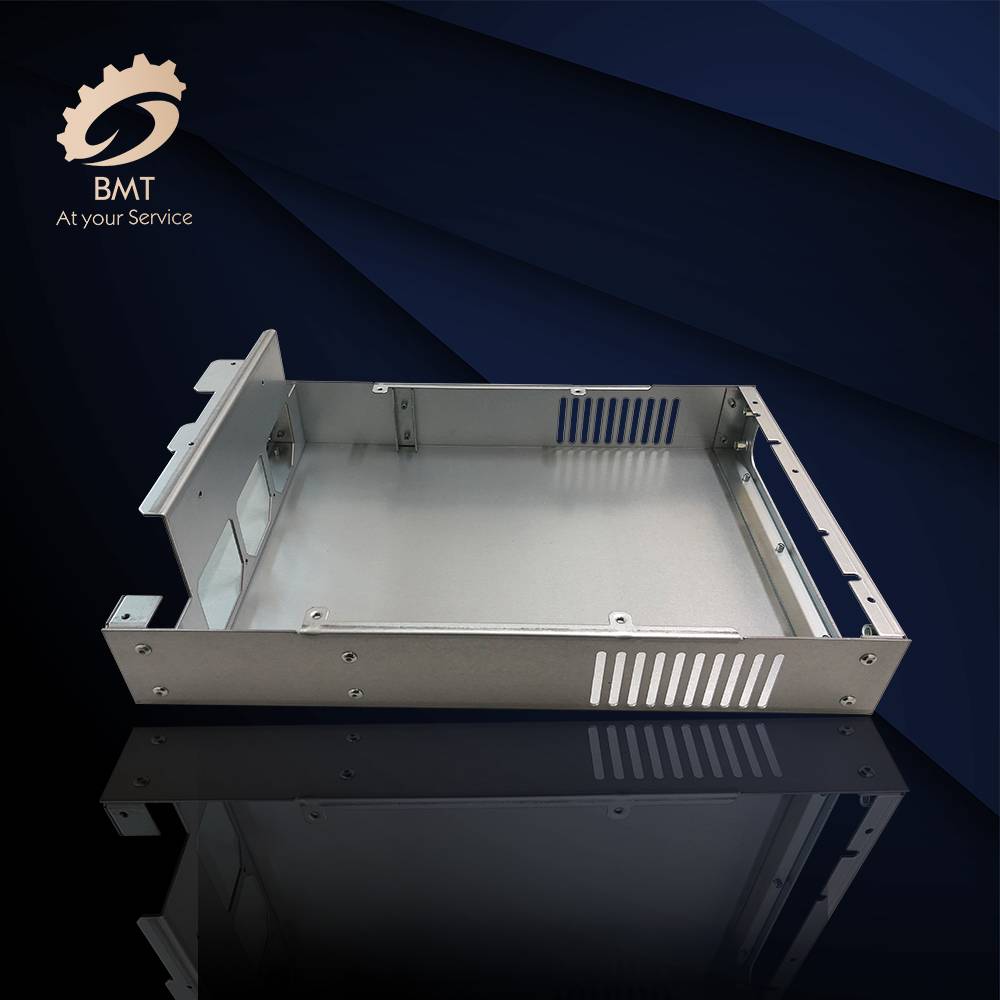

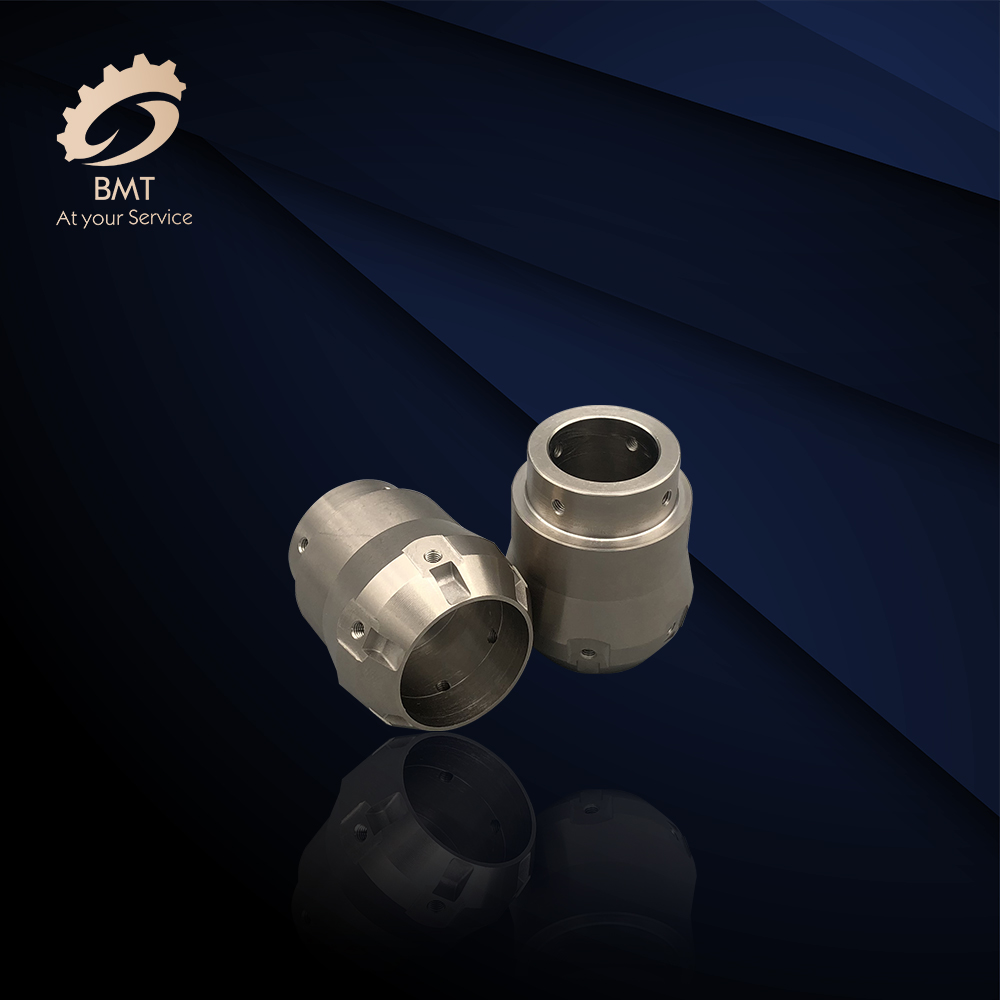

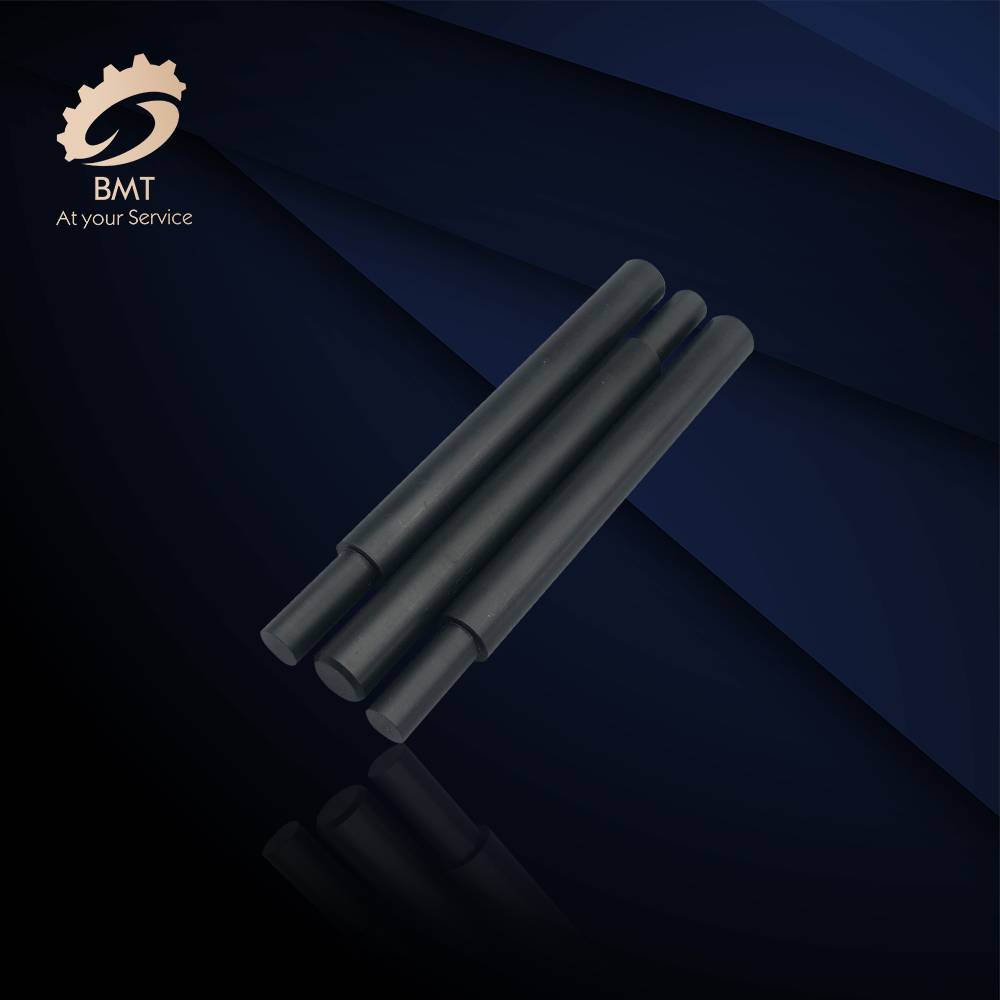

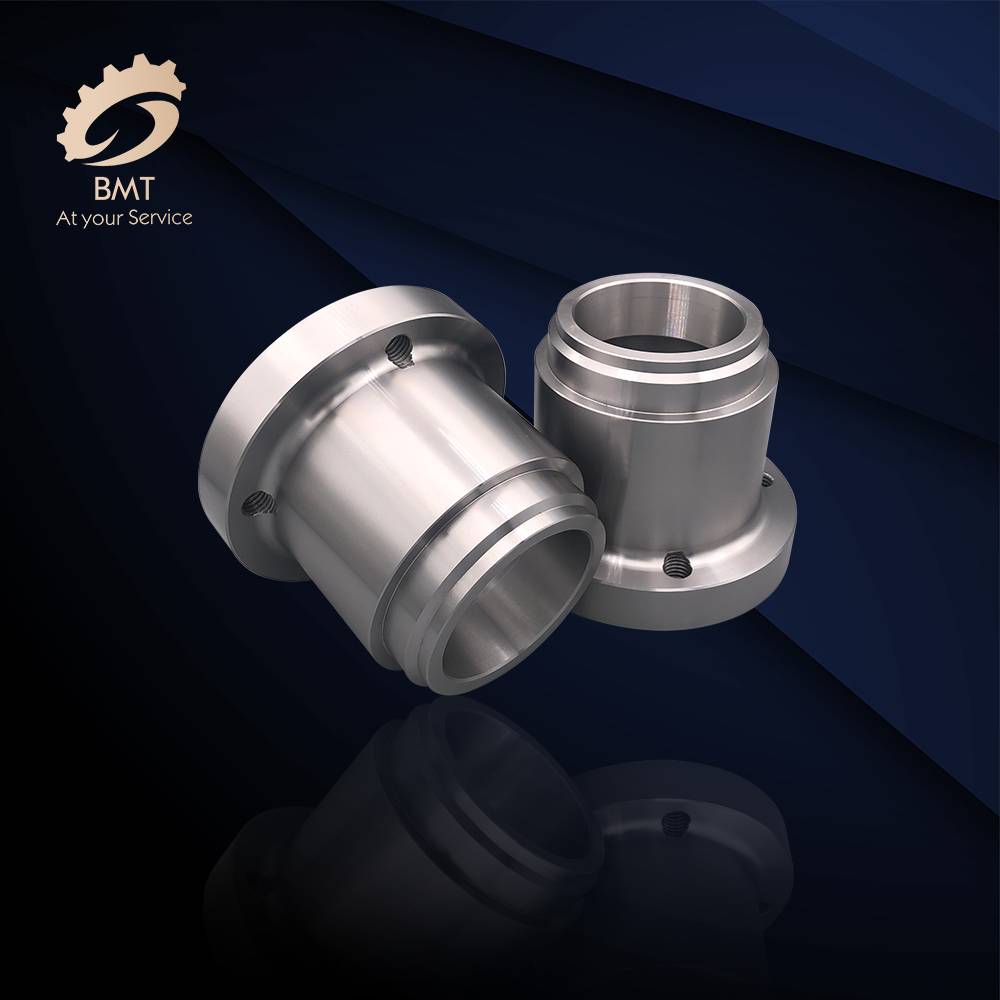

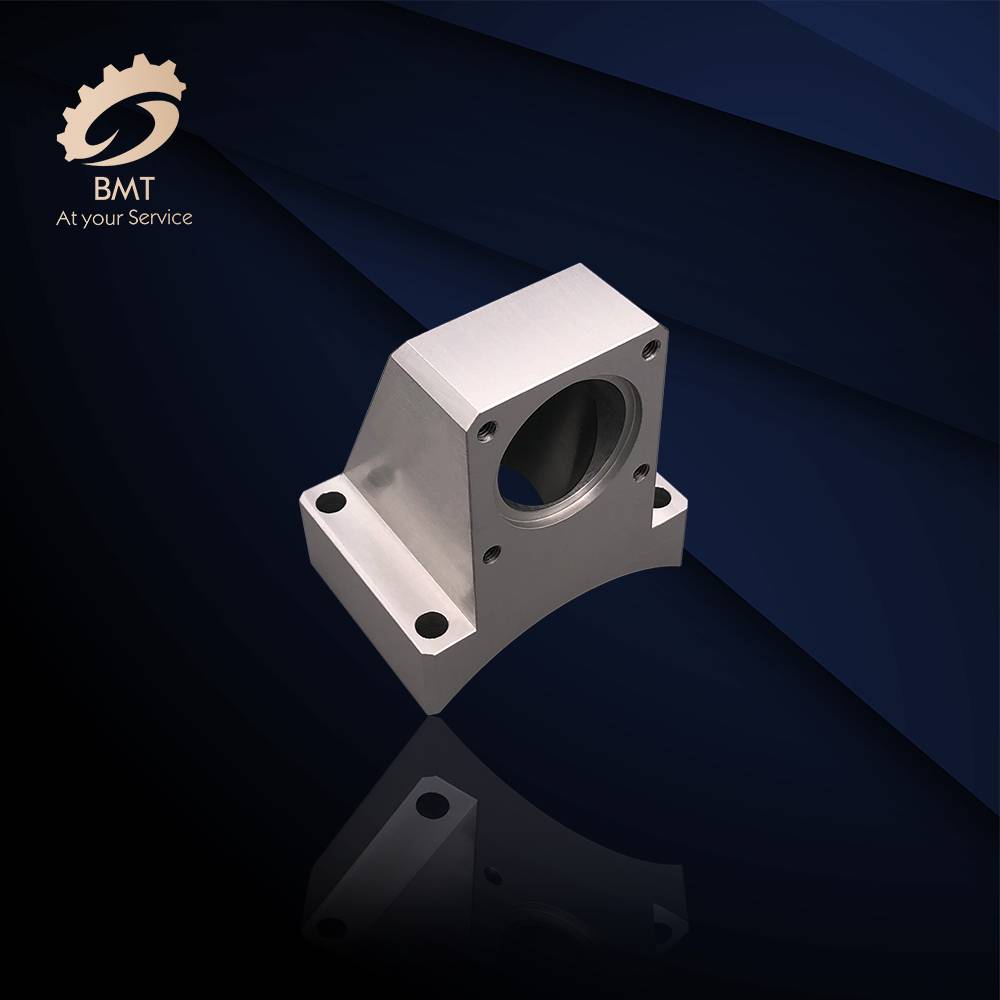

Product Description

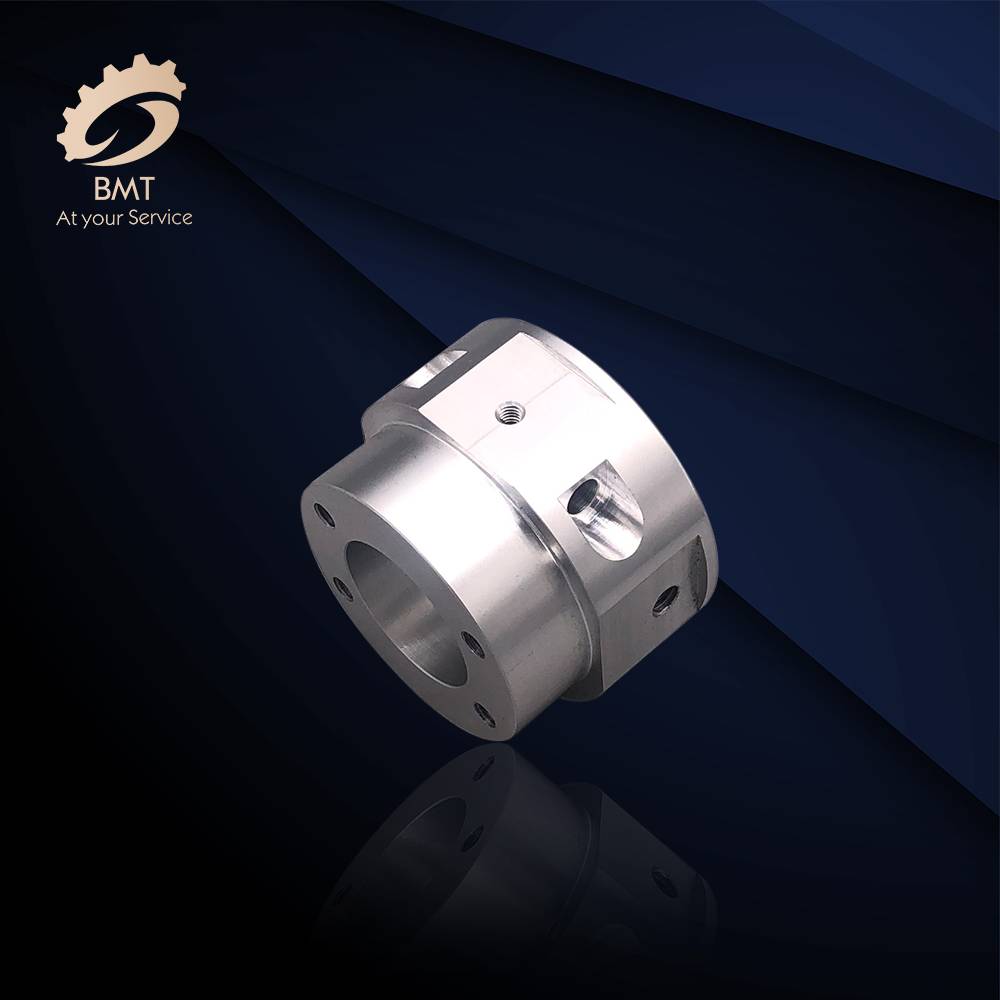

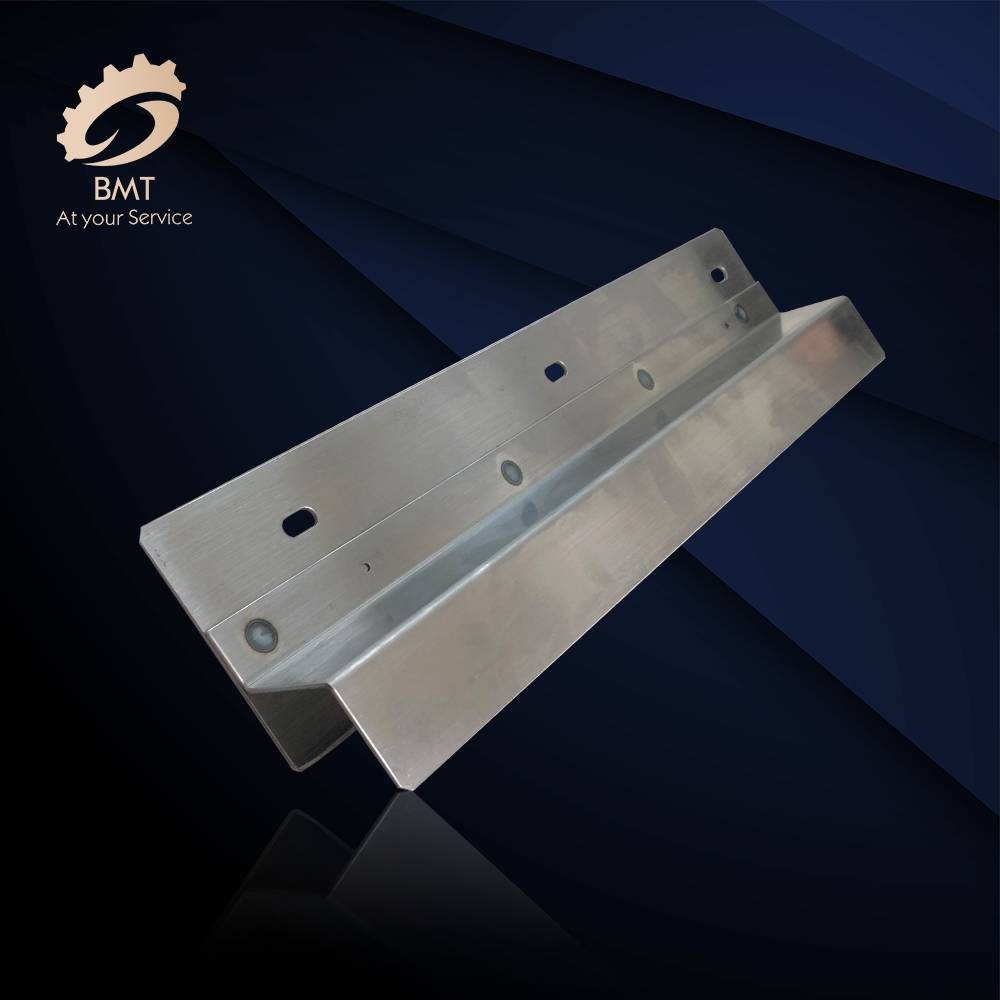

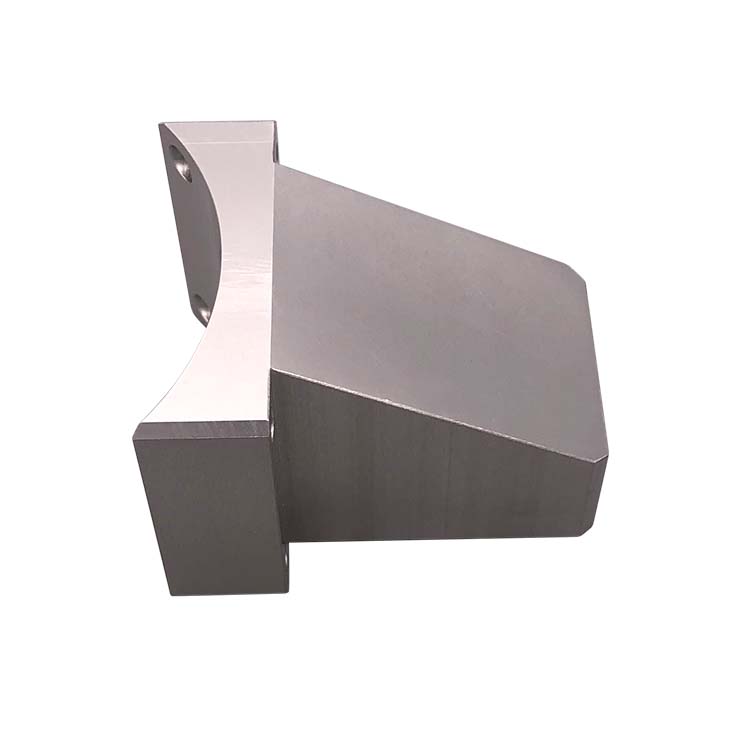

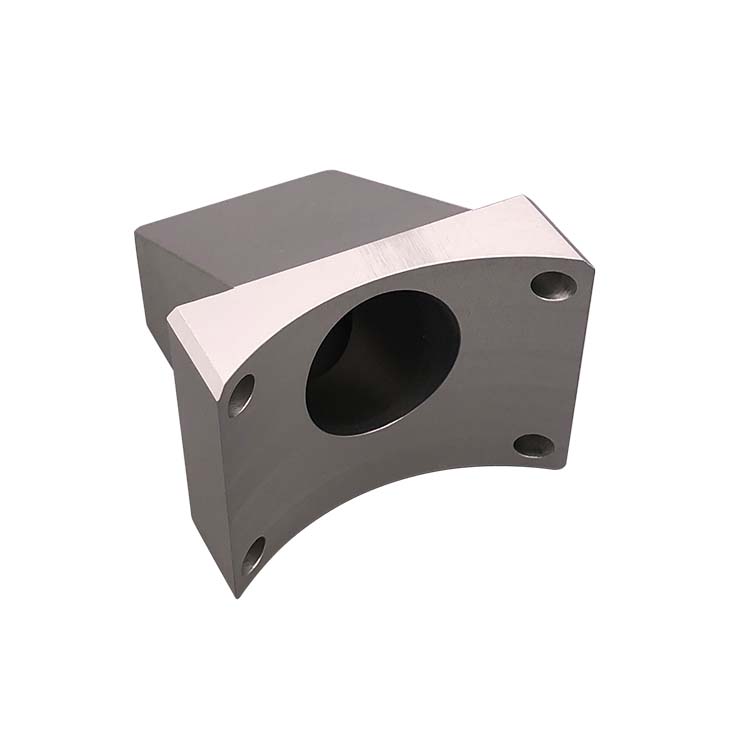

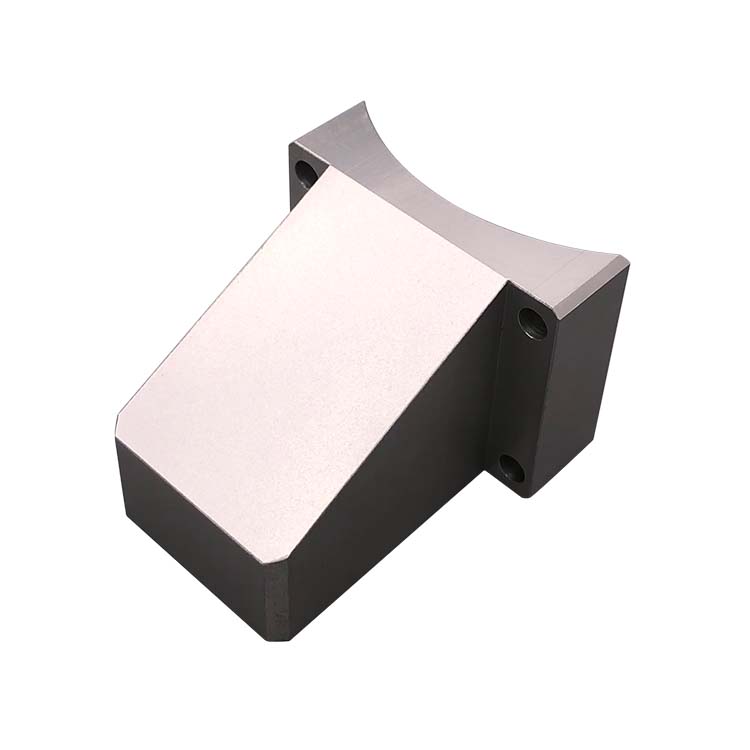

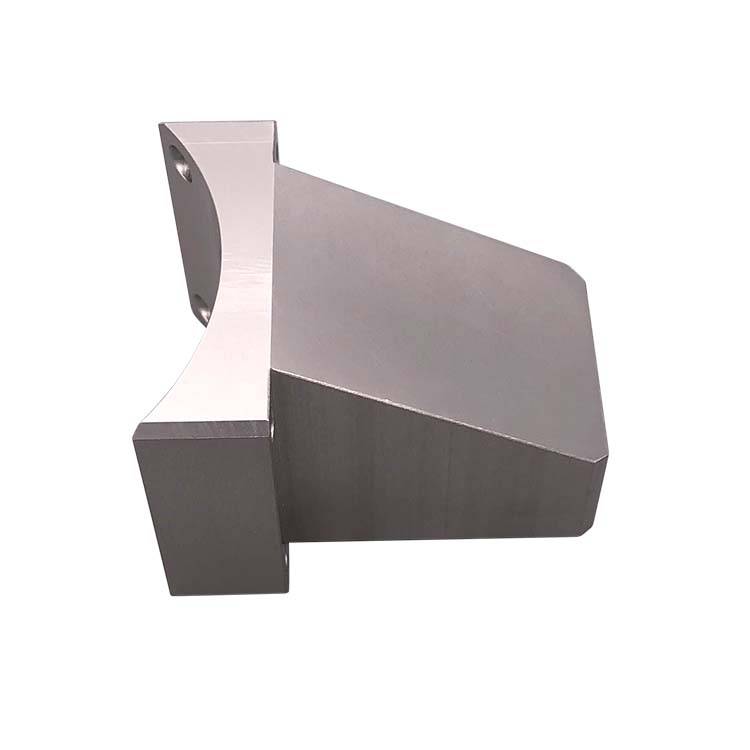

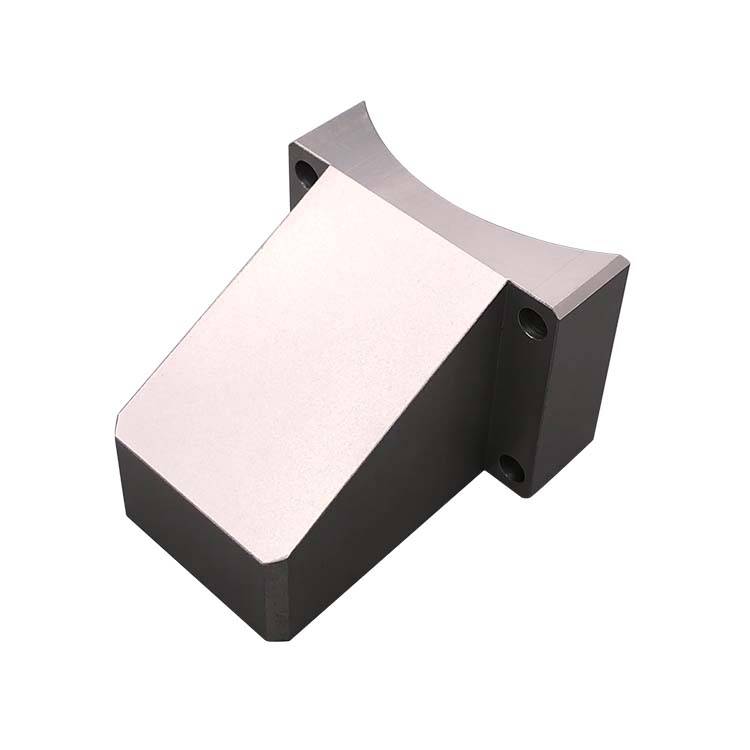

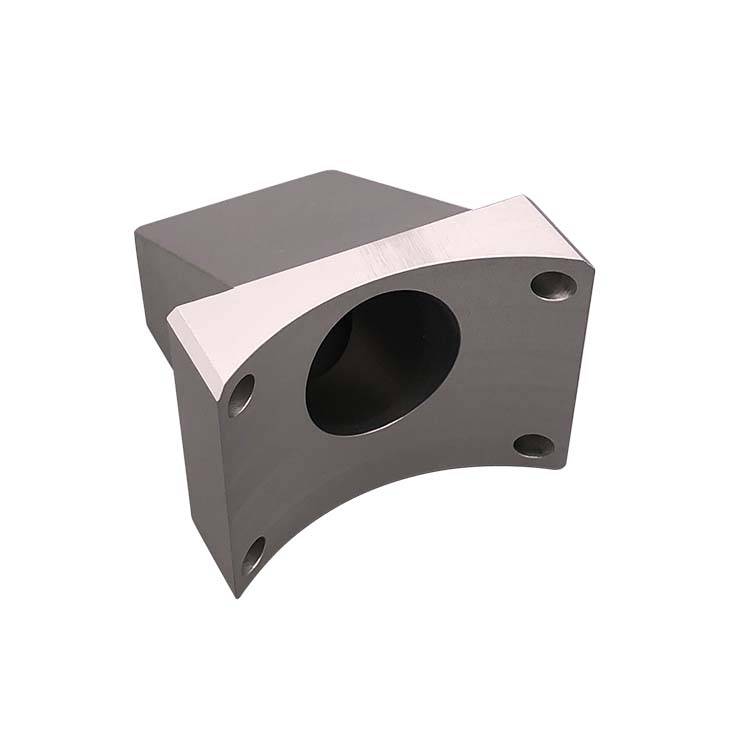

5 Axis Machining Parts

5 Axis Machining Parts

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for High Quality for Lathe Machining Part - Stainless Steel Precision CNC Machining – Basile, The product will supply to all over the world, such as: Greece, Turin, Japan, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.