Hot New Products Precision Machining Parts - Factors that Impact the Complexity of a Part – Basile Detail:

Factors that Impact the Complexity of a Part

- Part Size

Size alone doesn’t determine the part’s complexity, but can be a factor. Bear in mind, occasionally larger planar parts are less challenging than smaller, more intricate parts. Also, consider the size of individual features, as this affects the size of the cutting tool which will be used. A larger, high-speed cutting tool can remove material more quickly, reducing the machining time.

- Part processing

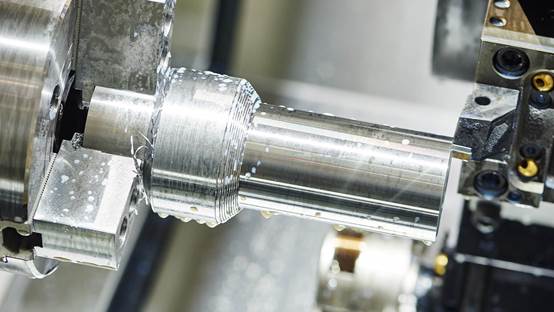

The number of operations, interventions and checks needed on the part will also impact the part complexity. Depending on the geometry, finishes and tolerances etc., the order of operations may be complex, time-consuming and detailed. For example, a complex part may require a number of reorientations and manual interventions. Occasionally, a 5 axis or mill-turn machine may be the most appropriate machine, for example, if it is cost-effective to produce or requires less overhead costs.

- Part tolerances

The part tolerances may impact the choice of CNC machine used and can also affect the cost and lead time. The achievable tolerance is also impacted by the material, machining speed and tooling. Simply put, the tighter the tolerance, the more your part will cost. Higher tolerances allow for more precision, but may also involve additional processes, operations, and tools and machines, thus adding to the cost.

Types of finishes

- Bead Blasting

Bead Blasting involves the removal of any surface deposits or imperfections on a part for a more uniform, smooth finish. The sphere-shaped beads ensure a consistent finish and are commonly used to offer a matt finish. Finer beads can also be used for a more satin-like or dull finish.

- Anodized finishes

Anodized finishes offer a specified wear-resistant coating, usually available in a number of colors. Anodizing is generally transparent, and the layer is usually thin so be sure to consider the CNC Machine marks on the surface.

- As machined

Another finish will leave the surface roughness as the piece is machined. The exact service roughness is determined using Ra value. Typically the surface roughness for CNC machined parts is Ra 1.6-3.2µm.

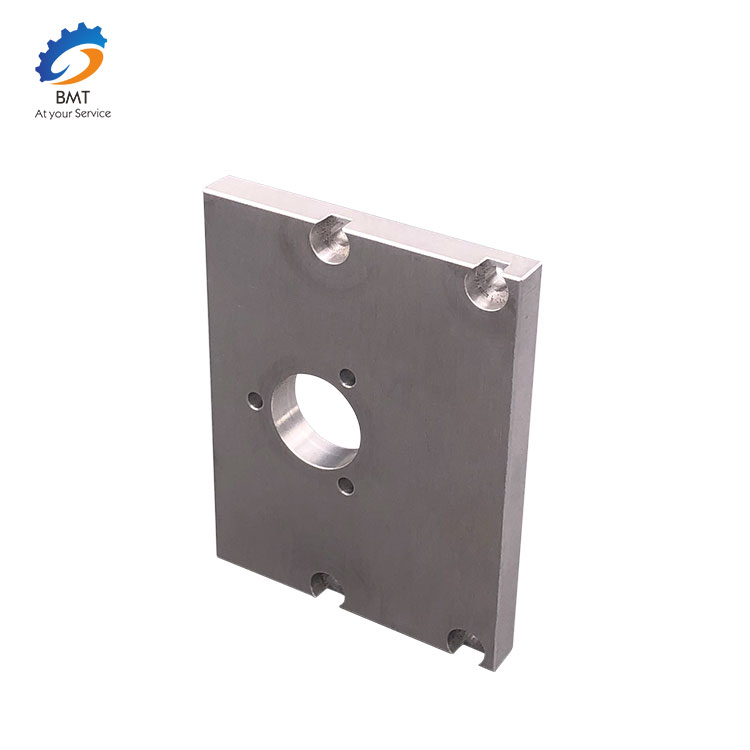

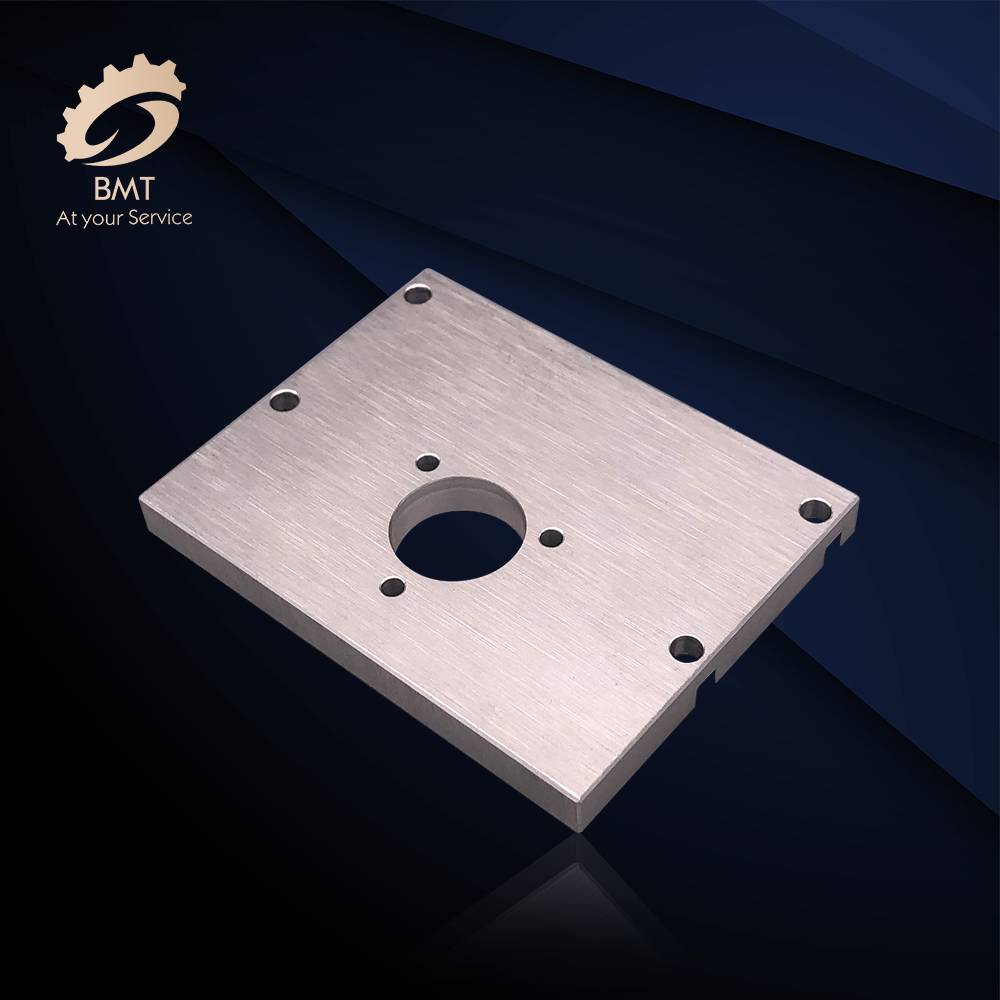

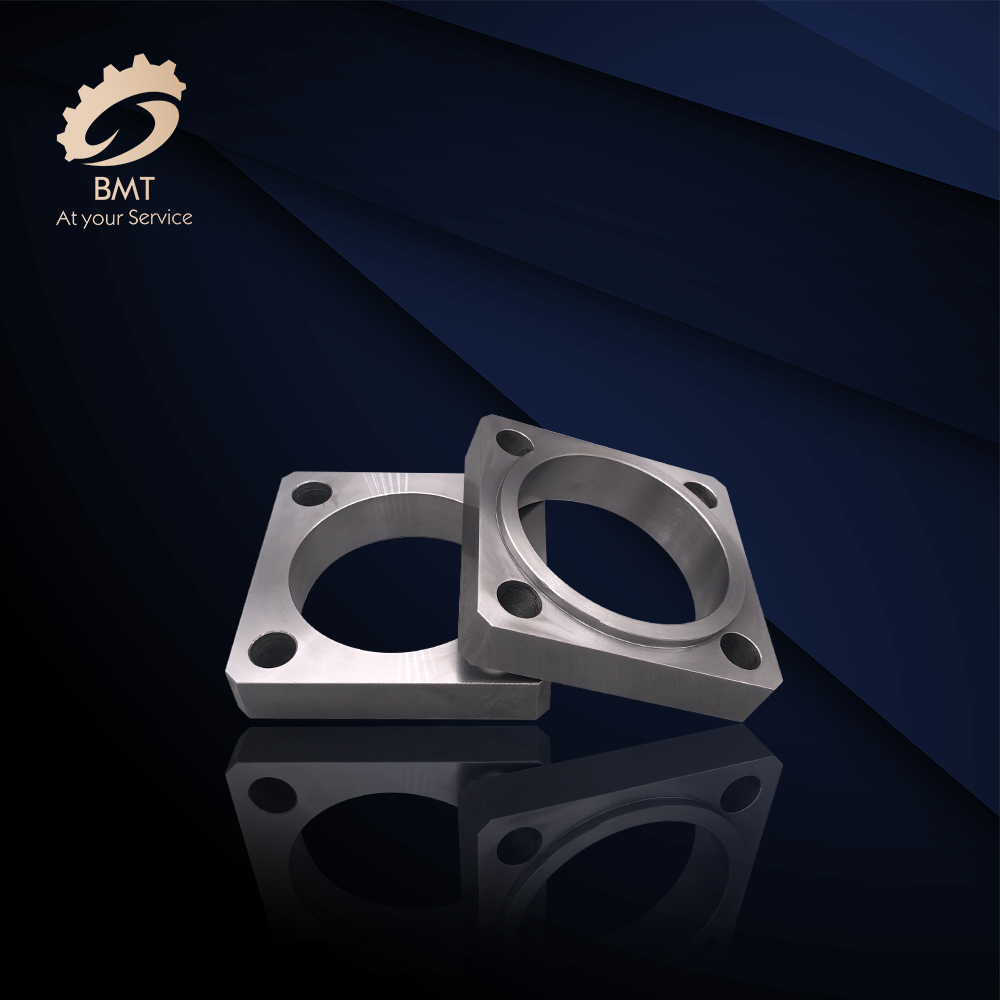

Product Description

Complexity of a Part

Complexity of a Part

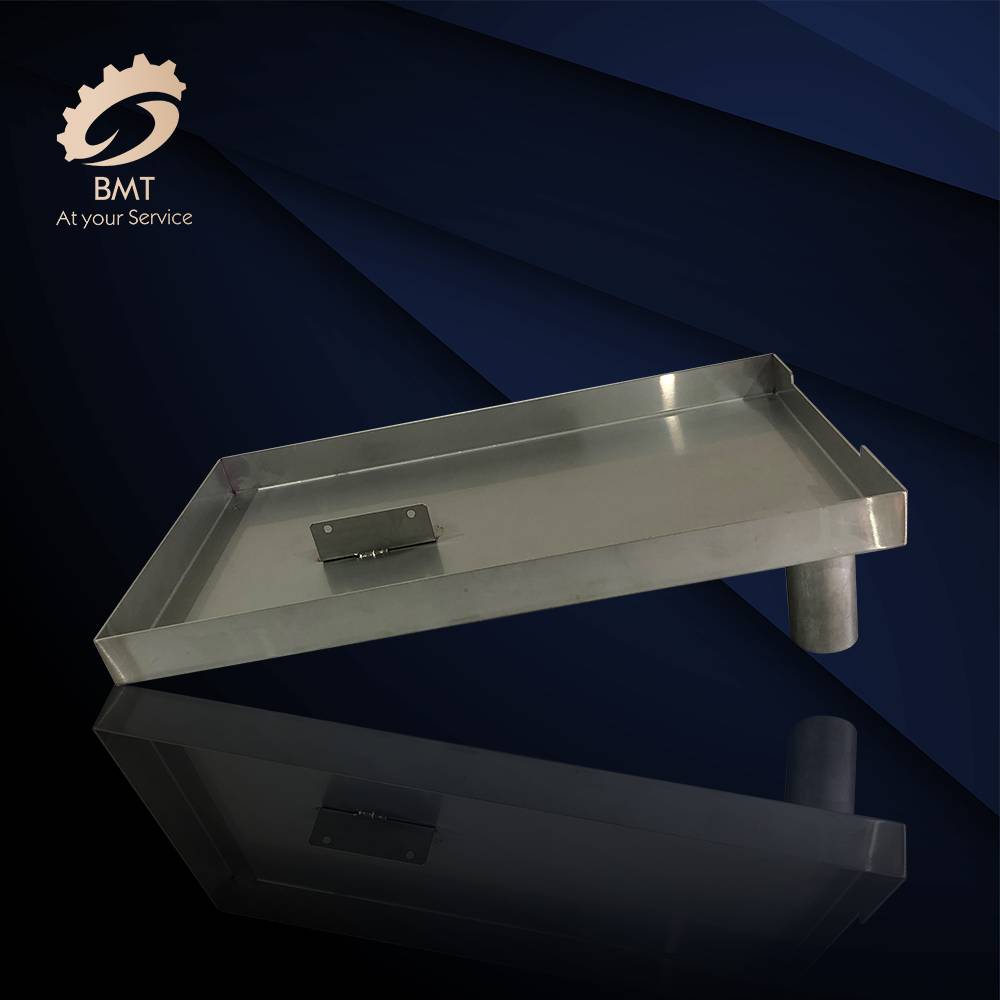

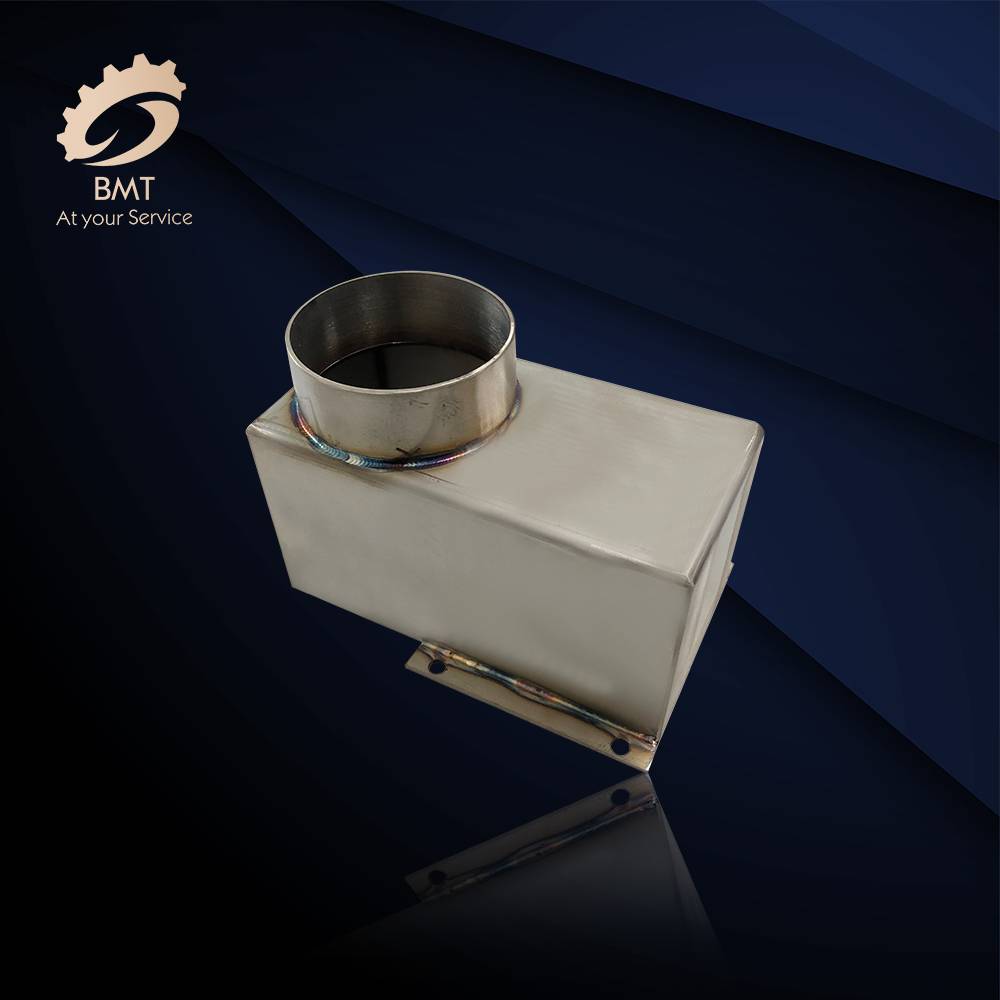

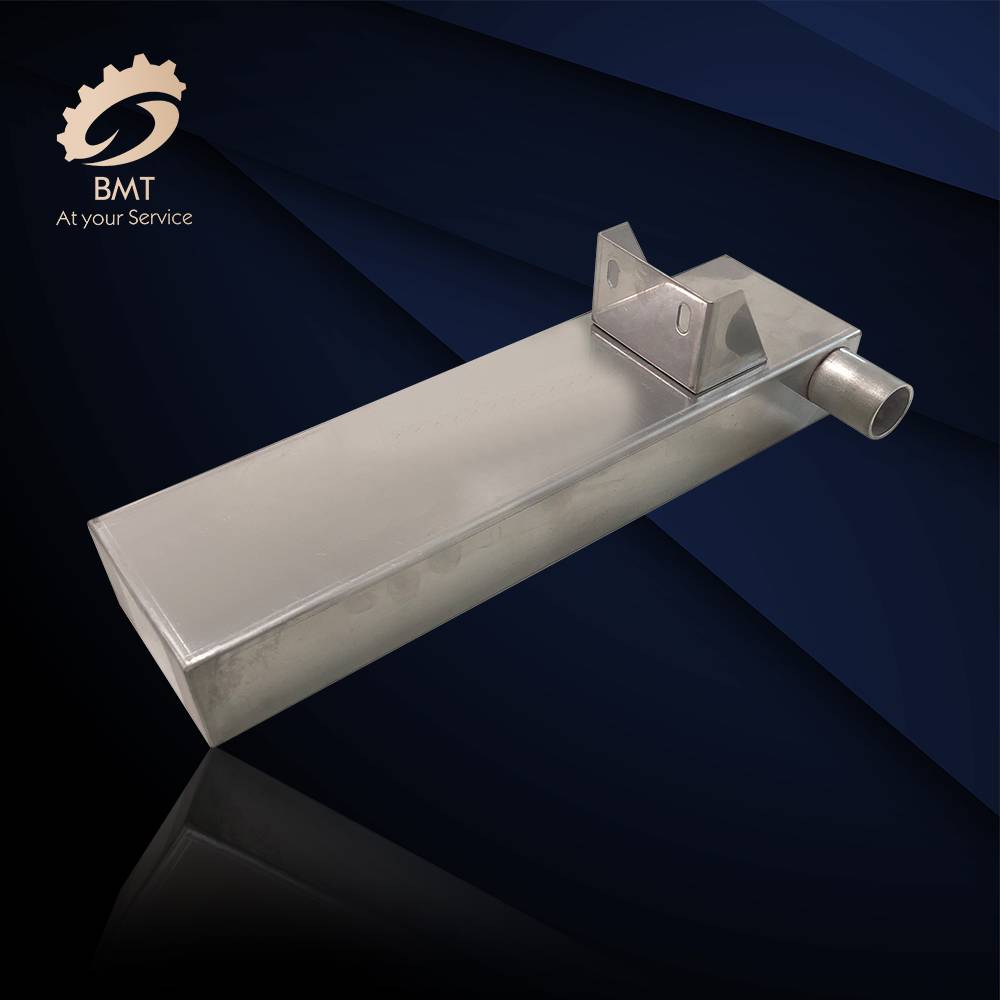

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for Hot New Products Precision Machining Parts - Factors that Impact the Complexity of a Part – Basile, The product will supply to all over the world, such as: Czech republic, Denmark, Indonesia, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Send your message to us:

-

Massive Selection for Sheet Metal Product - Al...

-

Leading Manufacturer for Precision Metal Cuttin...

-

Professional Design Sheet Metal Working - Cust...

-

Fast delivery Sheet Metal Fab Shop - Precision...

-

Factory wholesale Sheet Metal Around Me - Stai...

-

Wholesale Discount Sheet Metal Prototype Servic...