Hot sale Factory Sheet Metal Services - Precision Sheet Metal Parts and Stamping Parts – Basile Detail:

Tolerance and Fabrication Tooling

First of all, you need to know that all sheet metal parts start flat, so the part design needs to follow with a common gauge for all features. However, you are able to have different thicknesses, but you have to weld them together, which leads to a higher cost.

In the second place, we need to take good care of the bend radius. The workpiece will have a big increase for the strain when the bend radius gets smaller, so it is important to design simple angled bends with a bigger radius.

Last but not least, the smaller for holes, the cost is higher during metal sheeting cutting progress. Besides, it may easily cause distortion issues during cutting. Thus, it is ideal to keep the hold size larger than the metal sheet material thickness.

In BMT Sheet metal fabrication, we have strict management about the fabrication tooling and tolerances, as we know tolerances are the most important part for sheet metal working. So, fabrication tooling considerations is very essential. Generally speaking, a complicated feature will ask for tooling which means additional time and cost. Therefore, it is advisable to make the design simple that allows for conventional press brake tooling and the other low-cost common tooling.

We seriously obey the management for customers’ tolerances requirements and keep uniform bend orientation. Typically speaking, a metal part can accept a loose tolerance for most of the features, only a few dimensions are critical for the function. By accepting a lower tolerance, we can have a lower defective rate and higher production rate. For this reason, we should only call out tight tolerances for the key features to lower the costs.

In addition, we need to know that we will need to make reorientation if the bends are not designed in the same direction, which causes additional manufacturing time and brings the cost up accordingly. For this reason, the designer should try to maintain uniform bends during fabrication progress design.

Product Description

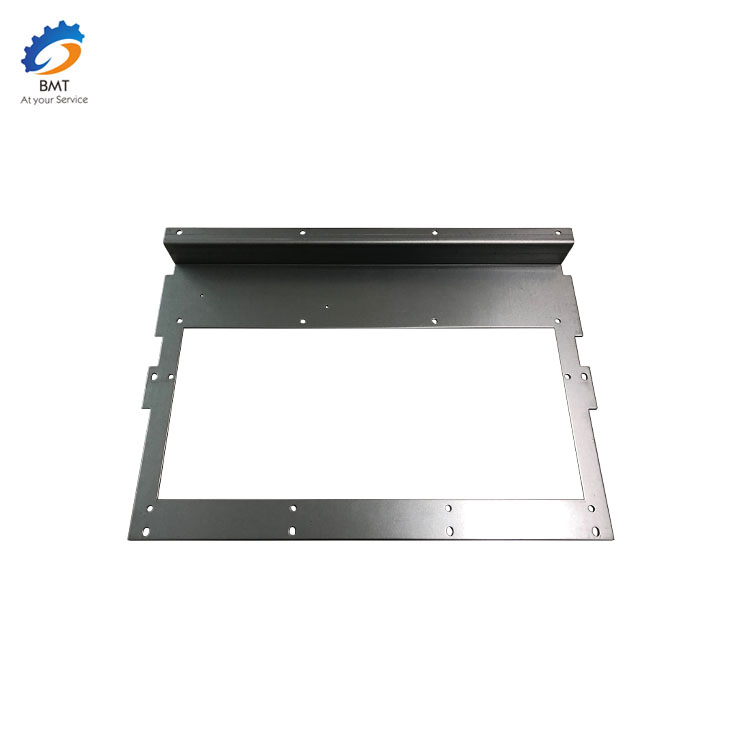

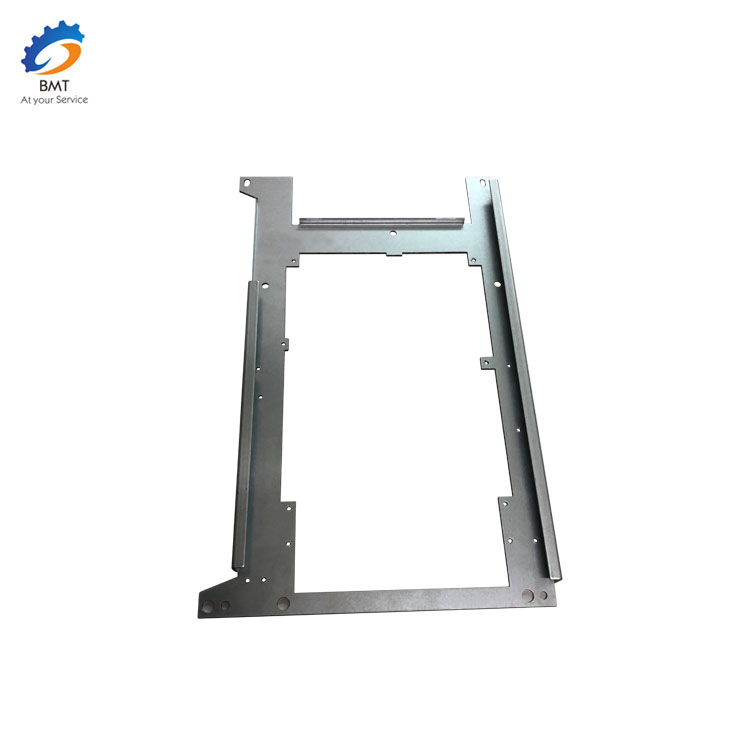

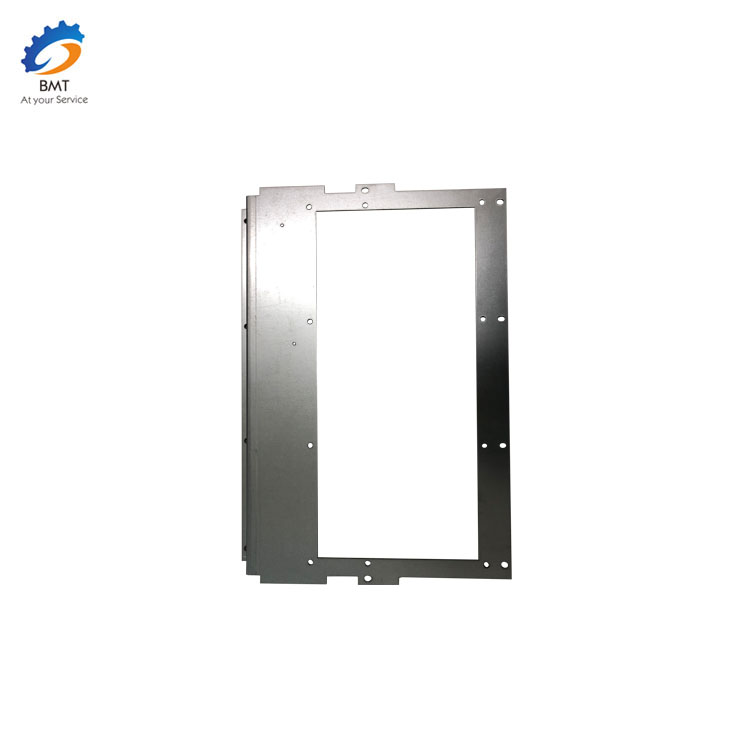

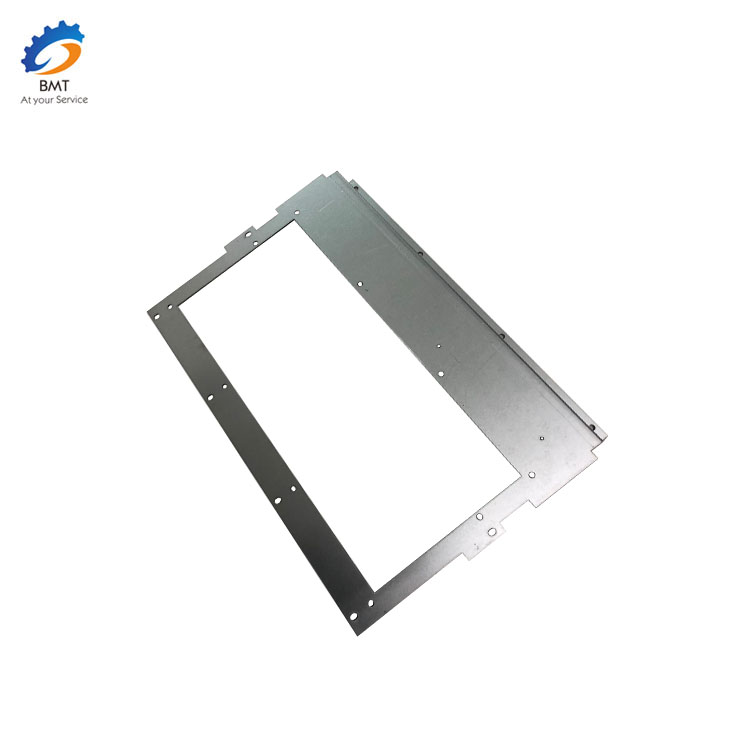

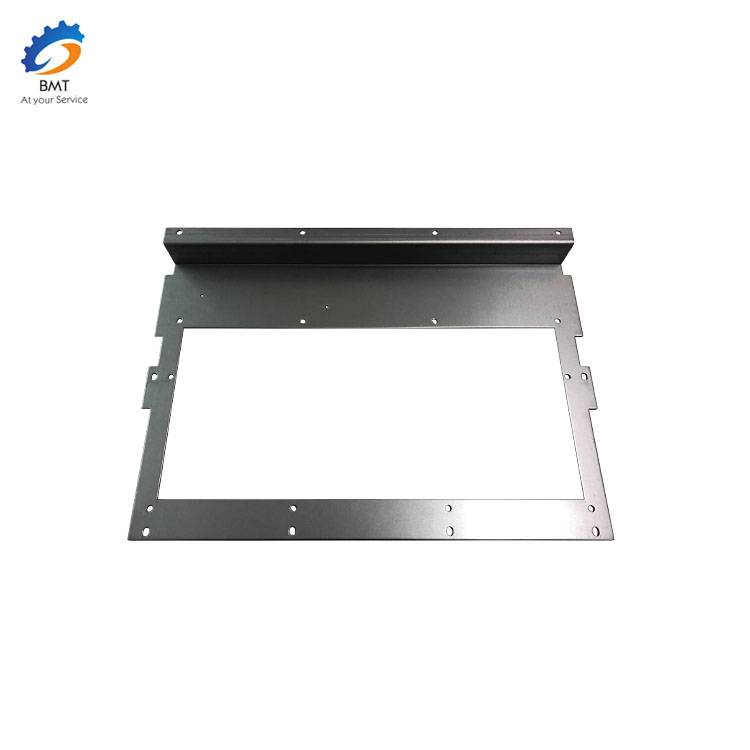

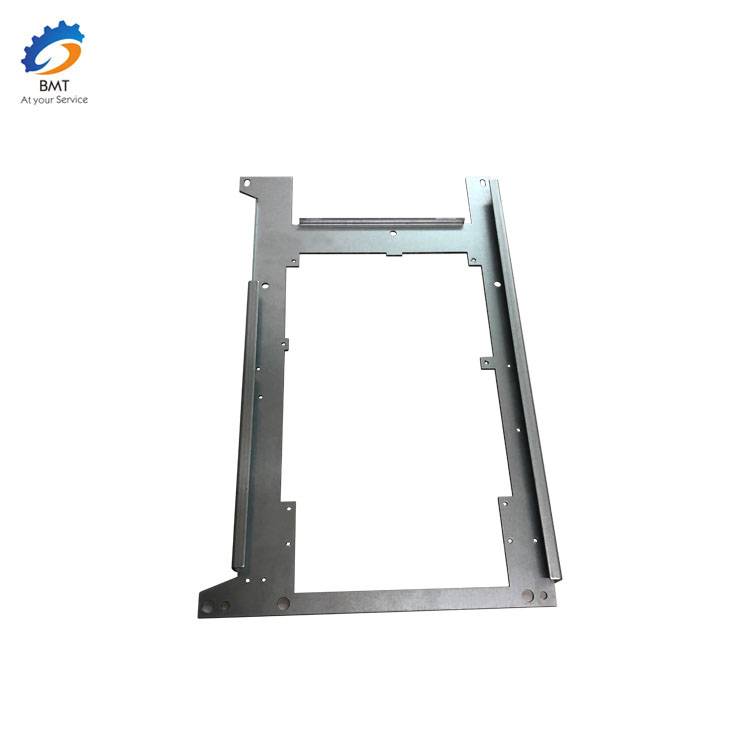

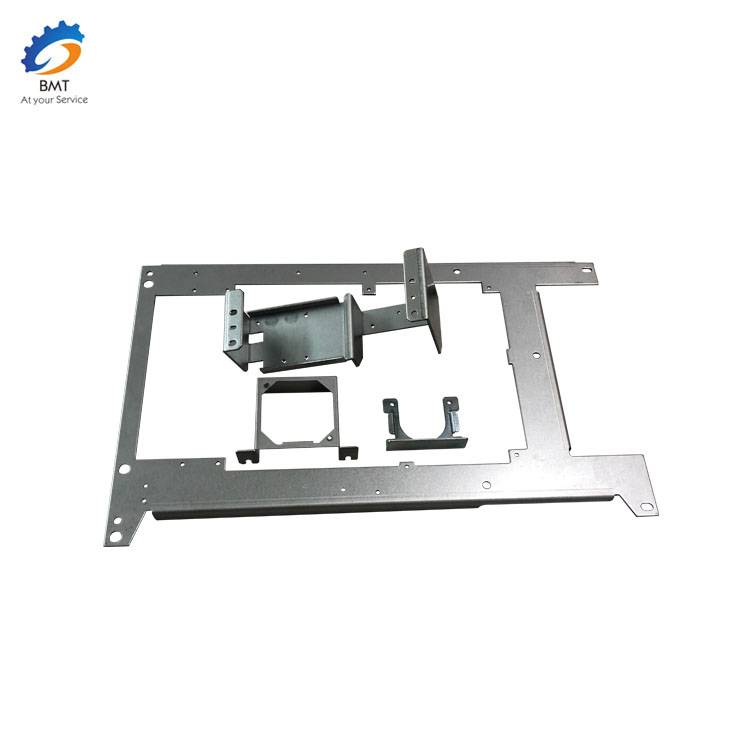

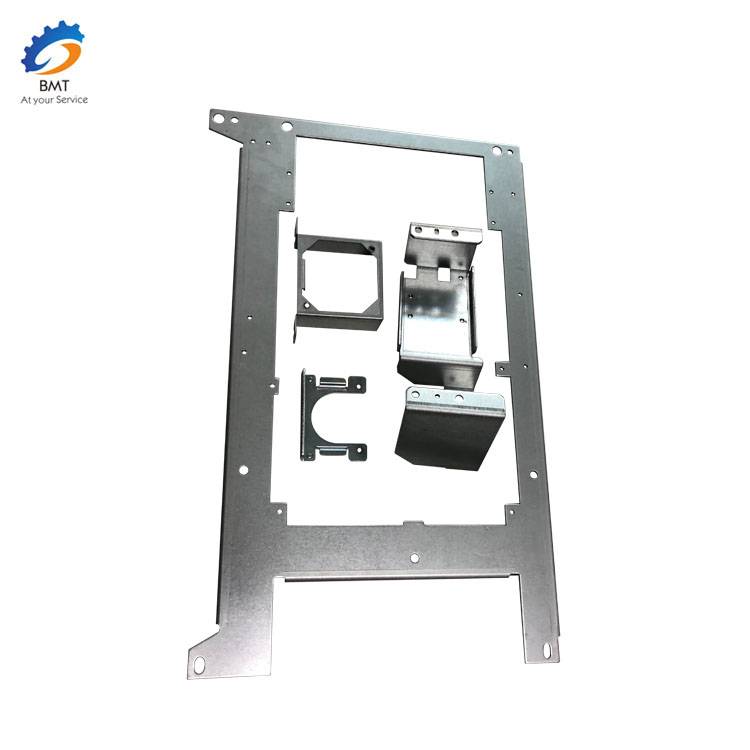

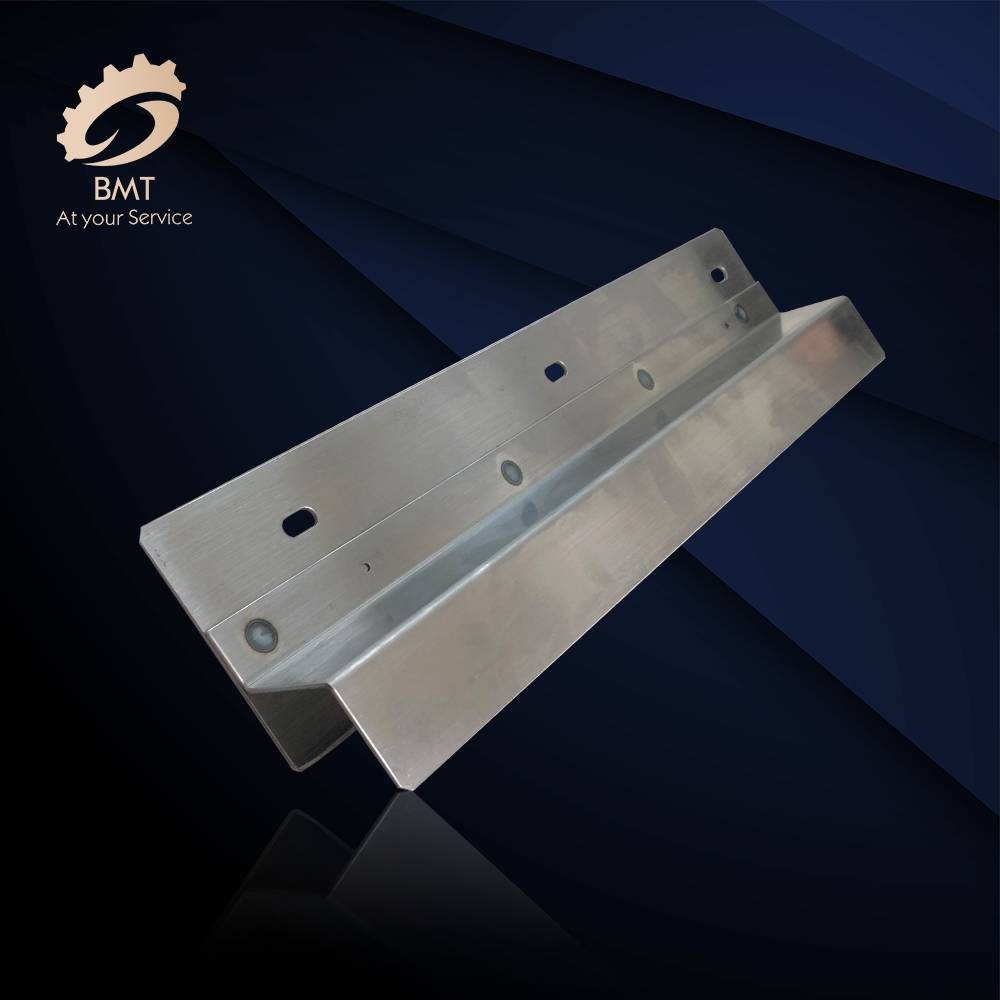

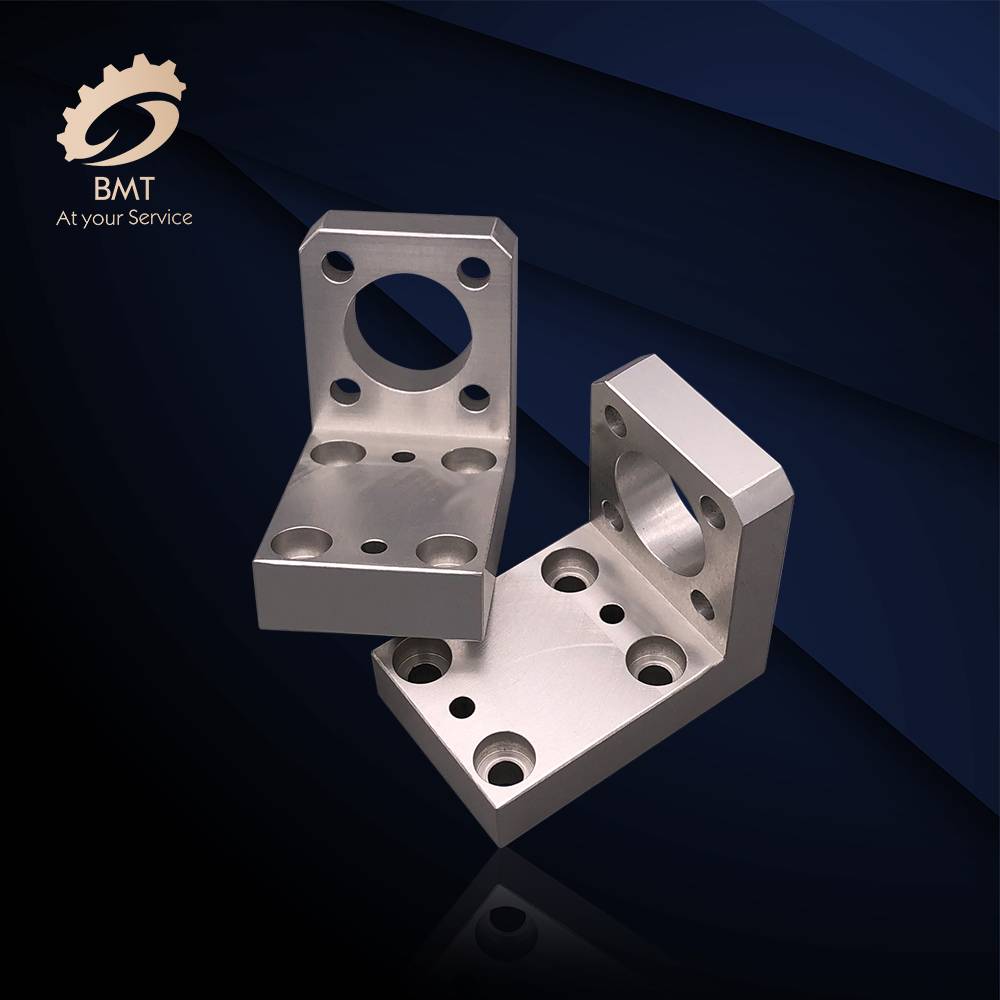

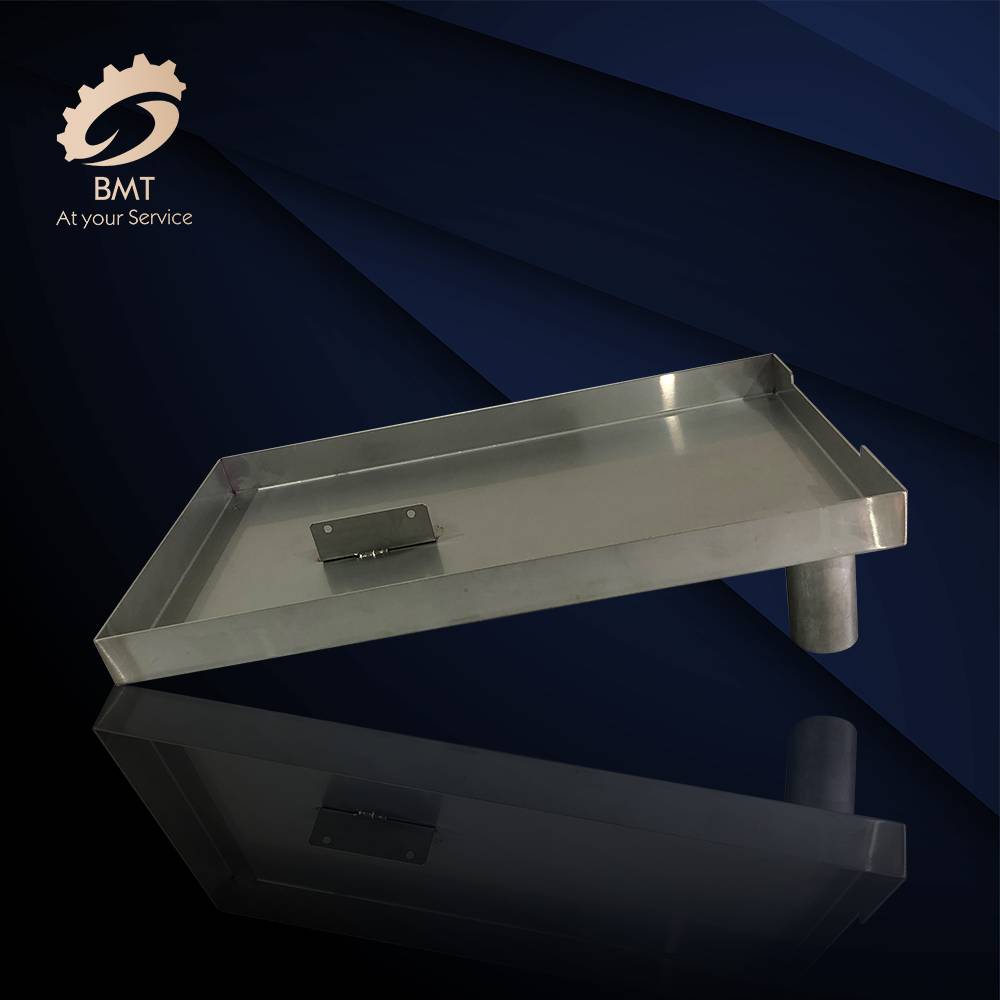

Precision Machining Parts

Precision Machining Parts

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" enterprise philosophy, a rigorous high-quality control process, superior production products along with a robust R&D group, we constantly deliver premium quality products, exceptional solutions and aggressive costs for Hot sale Factory Sheet Metal Services - Precision Sheet Metal Parts and Stamping Parts – Basile, The product will supply to all over the world, such as: Curacao, Australia, America, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

Send your message to us:

-

Discountable price Sheet Metal Box - Industria...

-

High Quality for Lathe Machining Part - Alumin...

-

Original Factory Lathe Machining - CNC Machine...

-

Newly Arrival Sheet Metal Fabrication Companie...

-

Factory Free sample Metal Duct Fabrication - P...

-

18 Years Factory Laser Cutting Service High Cus...