Hot Selling for Forging Machine Parts - CNC Machining Service Turning Parts – Basile Detail:

Types of CNC Machining Support Software

The CNC machining process employs software applications to ensure the optimization, precision, and accuracy of the custom-designed part or product. Software applications used include: CAD/CAM/CAE.

CAD: Computer-aided design software, the most commonly used software, are programs used to draft and produce 2D vector or 3D solid part and surface renderings, as well as the necessary technical documentation and specifications associated with the part. The designs and models generated in a CAD program are typically used by a CAM program to create the necessary machine program to produce the part via a CNC machining method. CAD software can also be used to determine and define optimal part properties, evaluate and verify part designs, simulate products without a prototype, and provide design data to manufacturers and job shops.

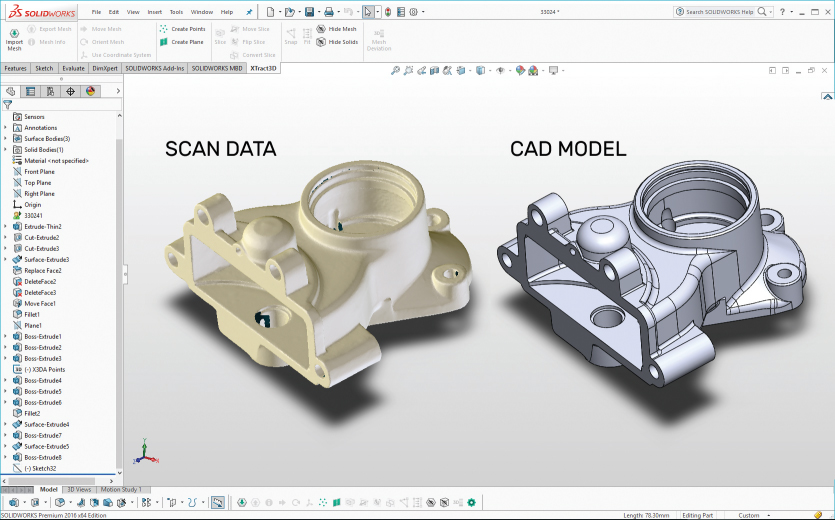

CAM: Computer-aided manufacturing software are programs used extract the technical information from the CAD model and generate machine program necessary to run the CNC machine and manipulate the tooling to produce the custom-designed part. CAM software enables the CNC machine to run without operator assistance and can help automate finished product evaluation.

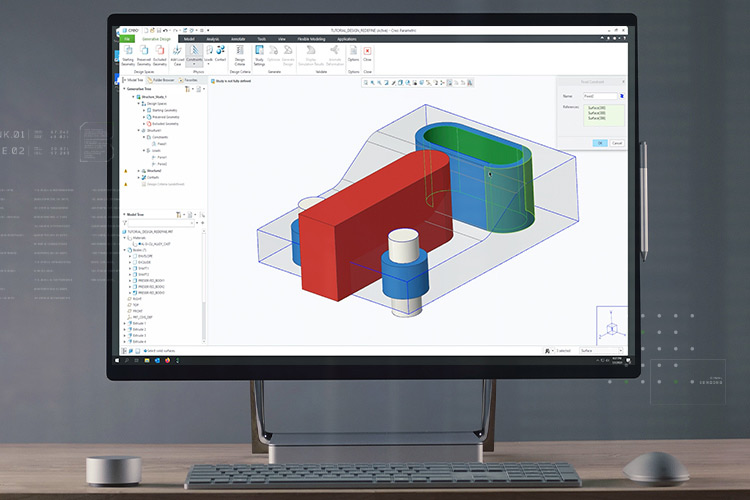

CAE: Computer-aided engineering software is a program used by engineers during the pre-processing, analysis, and post-processing phases of the development processes. CAE software is used as assistive support tools in engineering analysis applications, such as design, simulation, planning, manufacturing, diagnosis, and repair, to help with evaluating and modifying product design. Types of CAE software available include finite element analysis (FEA), computational fluid dynamics (CFD), and multibody dynamics (MDB) software.

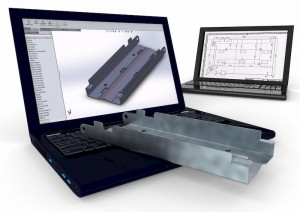

Some software applications have combined all of the aspects of CAD, CAM, and CAE software. This integrated program, typically referred to as CAD/CAM/CAE software, allows a single software program to manage the entire fabrication process from design to analysis to production.

How Does CNC Machining Work?

CNC machining can be simplified into a 3-step process:

✔ An engineer produces a CAD model of the part to be made.

✔ A machinist translates the CAD file to a CNC program and prepares the machine.

✔ The CNC program is initiated and the machine produces the part.

So, CAD/CAM/CAE software applications play an important role in CNC Machining. In order to increasing the machining capabilities, using the software well is essential.

Product Description

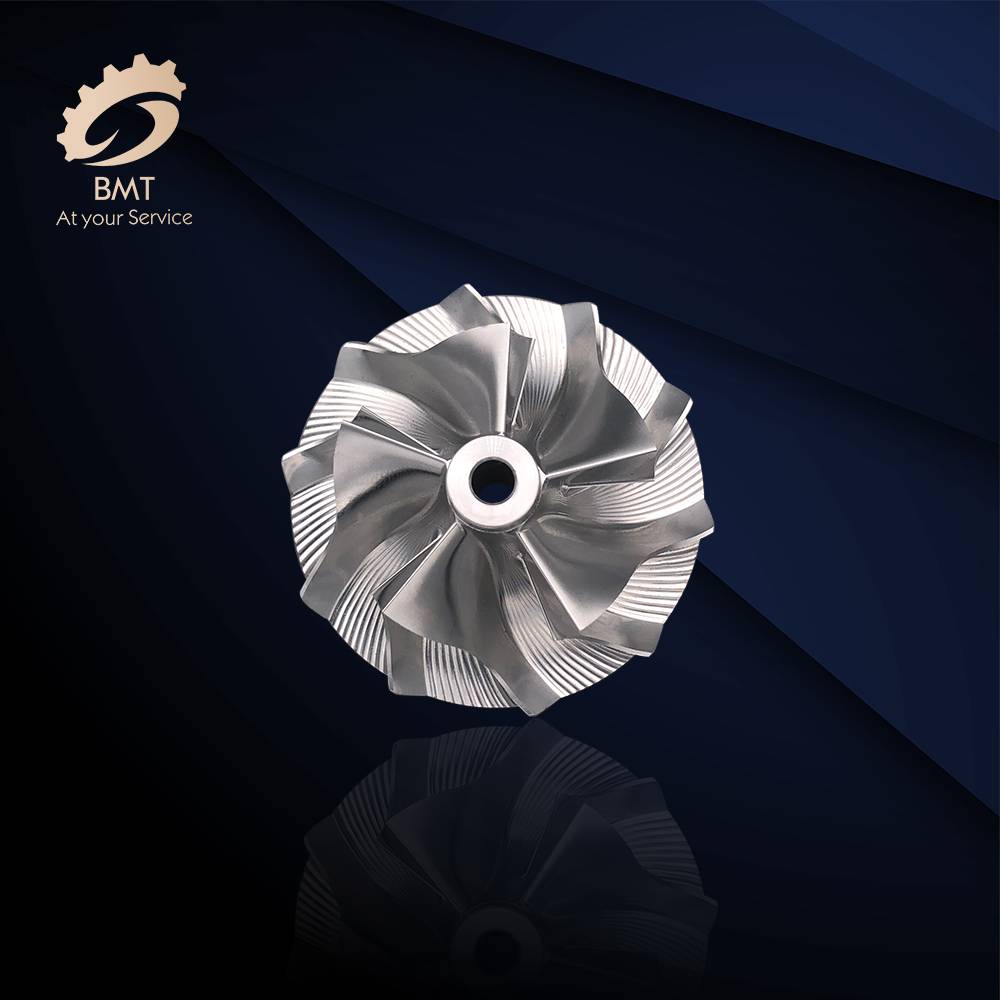

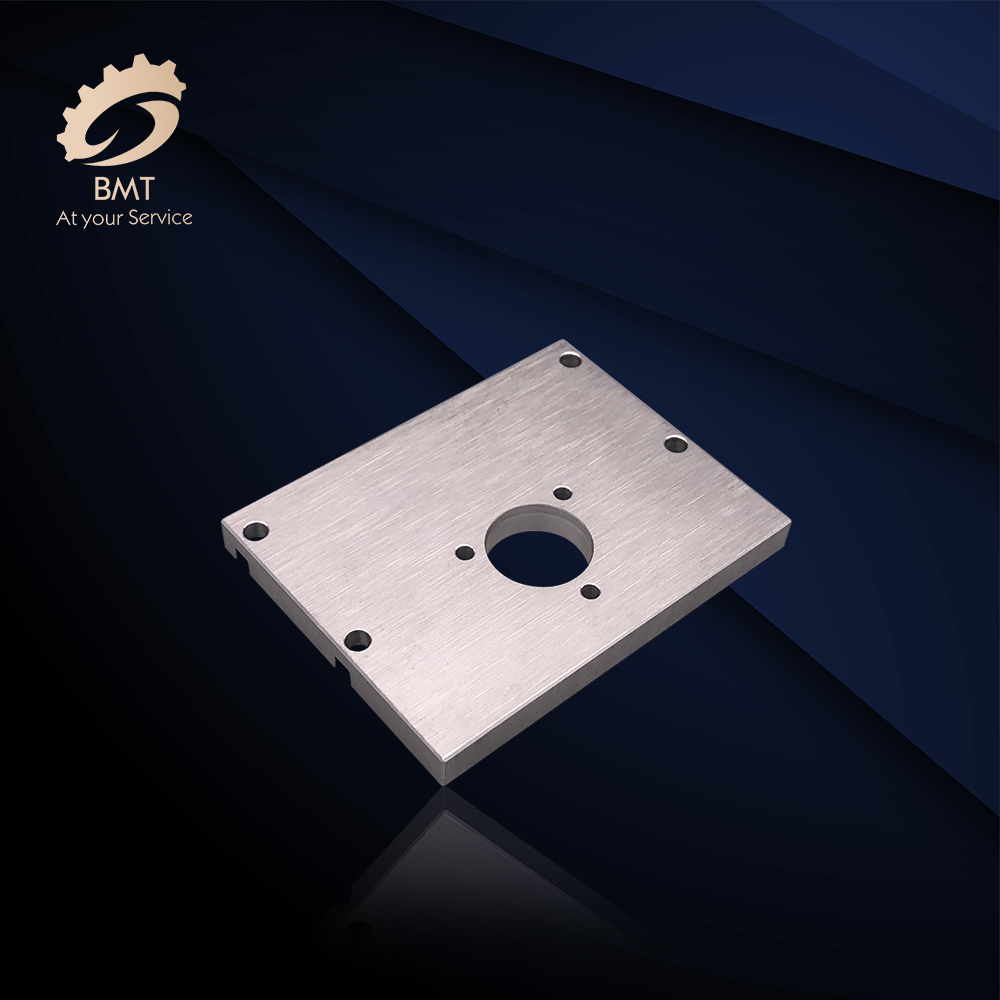

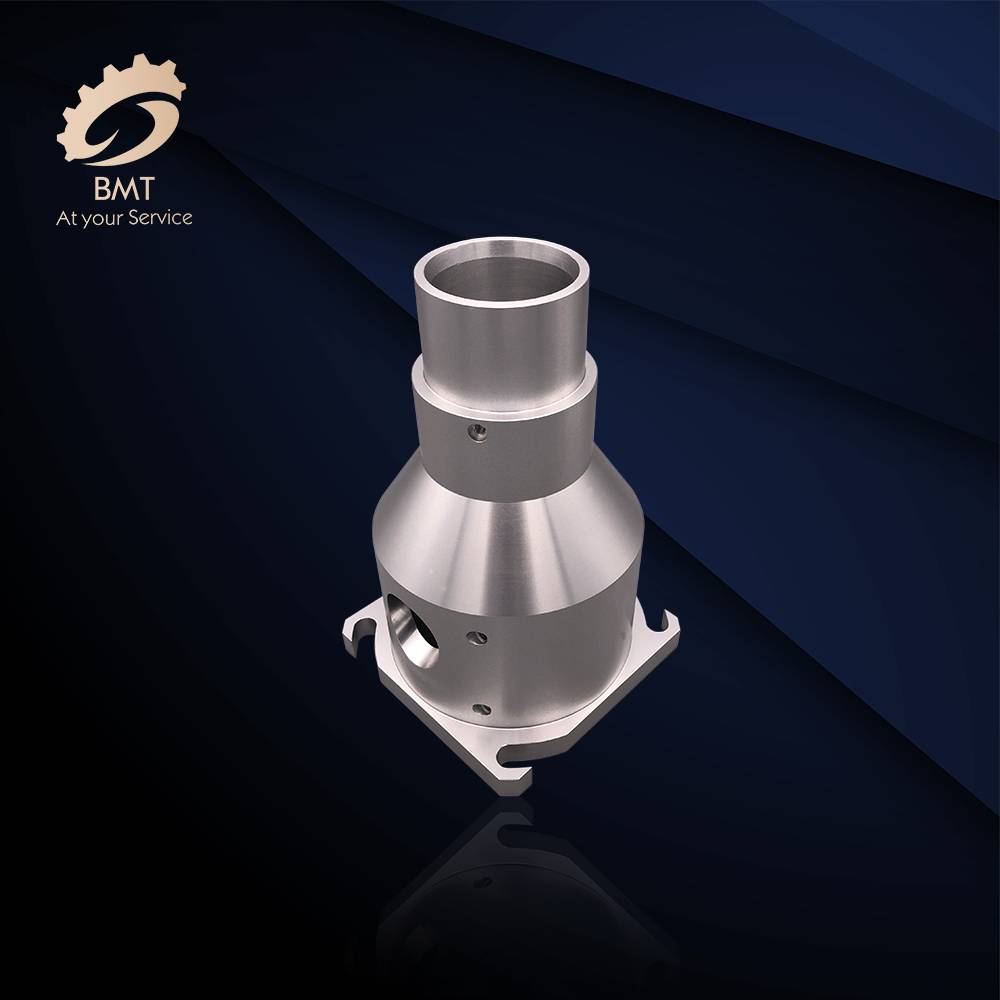

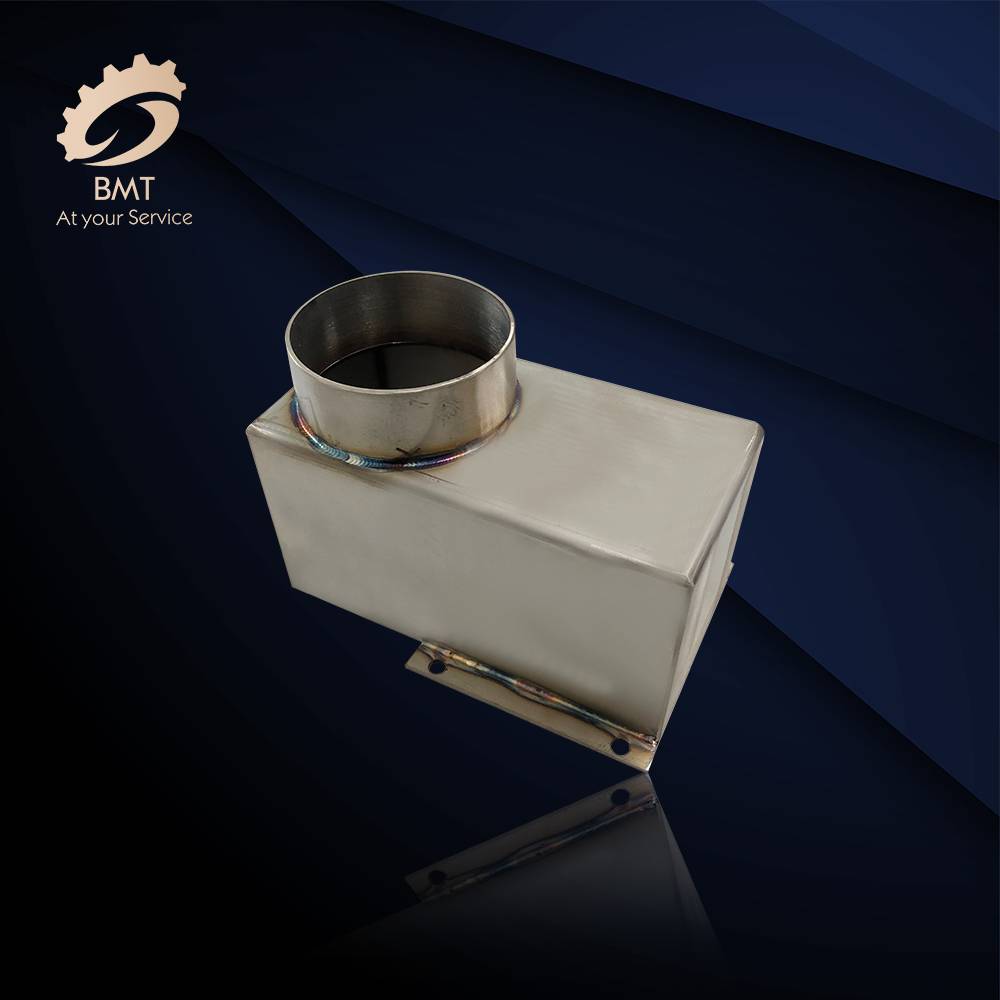

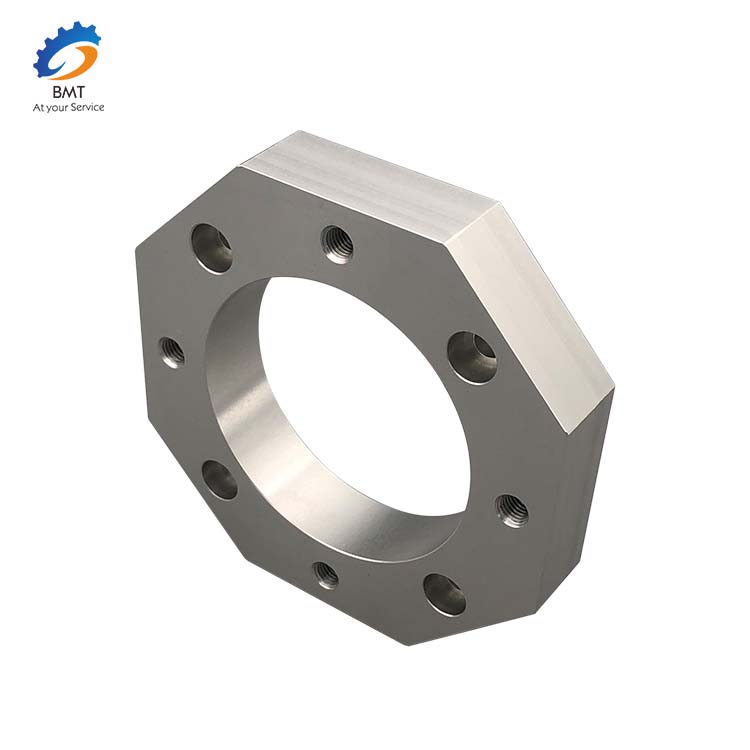

Stainless Steel CNC Milling

CNC Milling Components

CNC Milling Stainless Steel

Stainless Steel CNC Milling

CNC Milling Components

CNC Milling Stainless Steel

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Hot Selling for Forging Machine Parts - CNC Machining Service Turning Parts – Basile, The product will supply to all over the world, such as: azerbaijan, Bandung, Luxemburg, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!