Manufacturer of Stainless Steel Precision Cnc Machining - Mechanical Parts Machining – Basile Detail:

BMT CNC Machining Surface Treatment

Sometimes, Customers choose metal surface treatment services after machining at BMT to improve the parts appearance, to get smooth surface, and to reach corrosion resistance, etc. With more than 10 years’ experience with CNC Precision Machining Parts and learned from customers, our customers usually choose Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Heat treatment, Powder Coated, etc. What is the difference between these surface treatments?

|

Electroplating |

A process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts. |

|

|

Polishing |

A process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, make the surface get significant specular reflection or reduce diffuse reflection in some materials. |

|

|

Painting |

Refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation. |

|

|

Passivation |

A common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. |

|

|

Powder coating |

A functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts. |

|

|

Anodizing |

An electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum. |

|

|

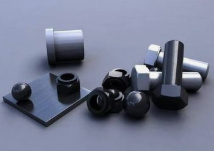

Black oxide |

A chemical process of forming a black conversion coating on stainless steel, copper and copper based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection. |  |

|

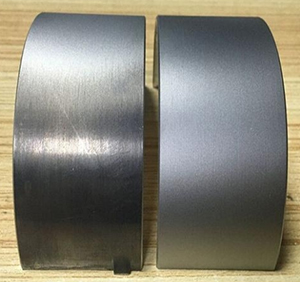

Abrasive blasting/ Sandblasting |

The process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals or increase a texture, then change the smoothness or roughness of surface. |

|

|

Phosphating |

A chemical process for treating the surface of steel, where barely soluble metal-phosphate layers are formed on the base material. The layers created are porous, absorbent and suitable as a conversion layer for subsequent powder coating without further treatment. |  |

BMT also provides grinding, industrial etching, and more custom metal finishing service for presenting the best effect of your part. Just tell us what you need and we will take care of the rest!

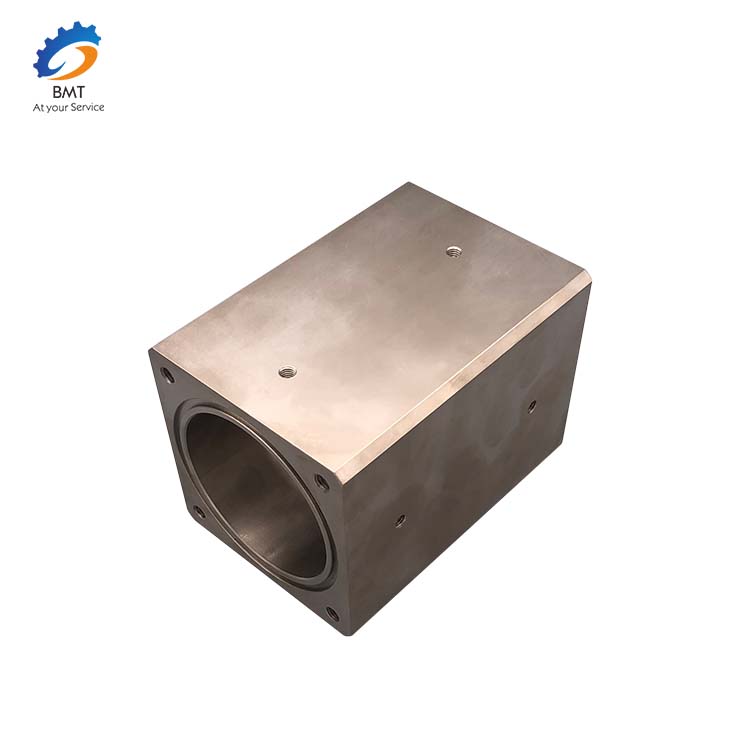

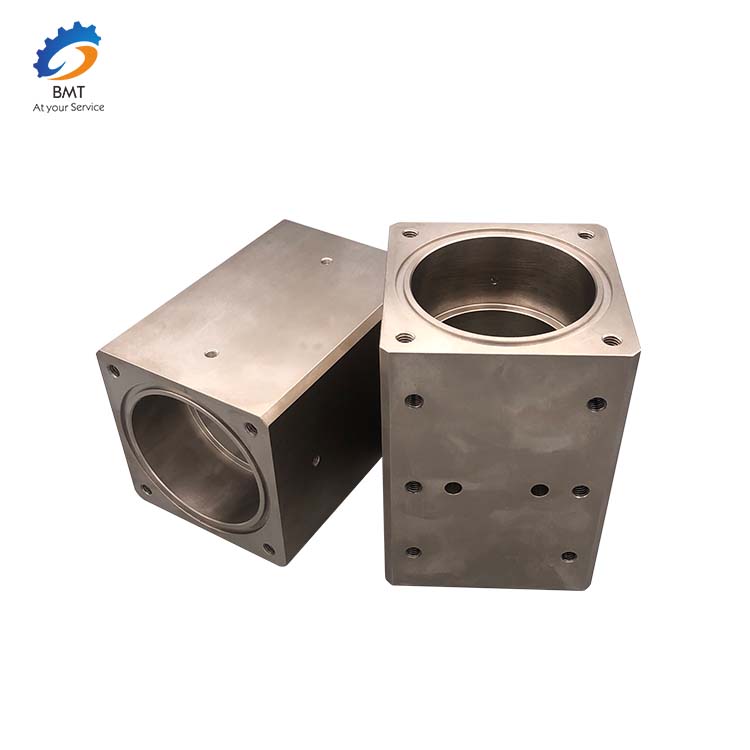

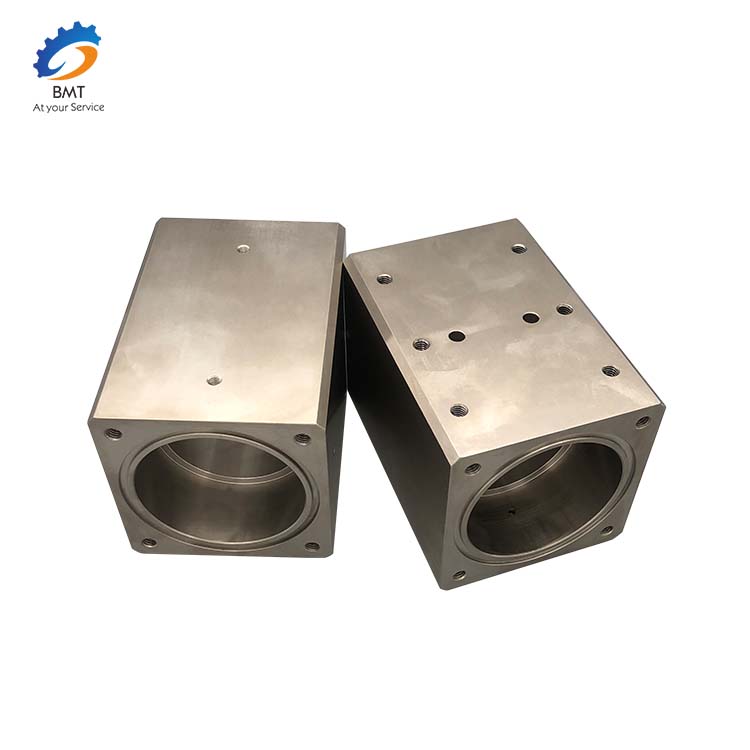

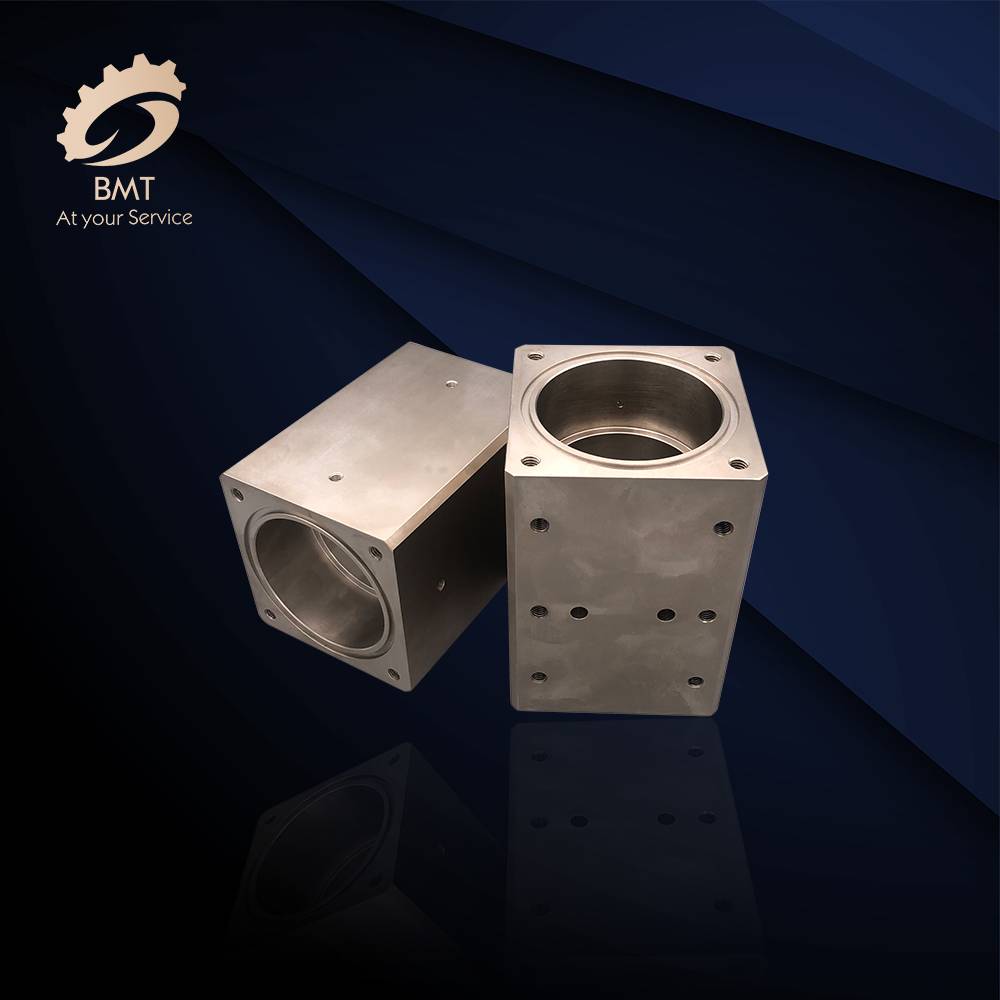

Product Description

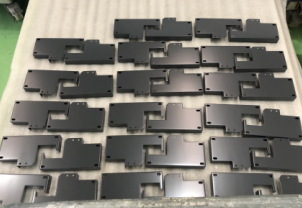

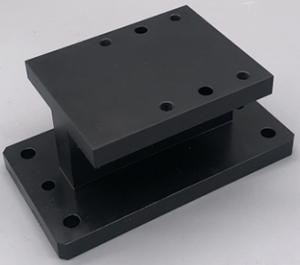

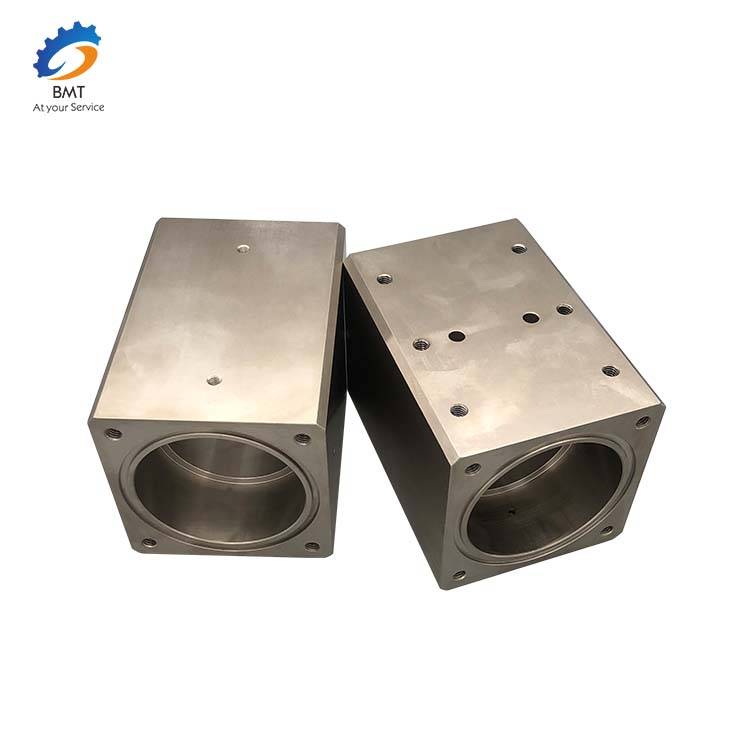

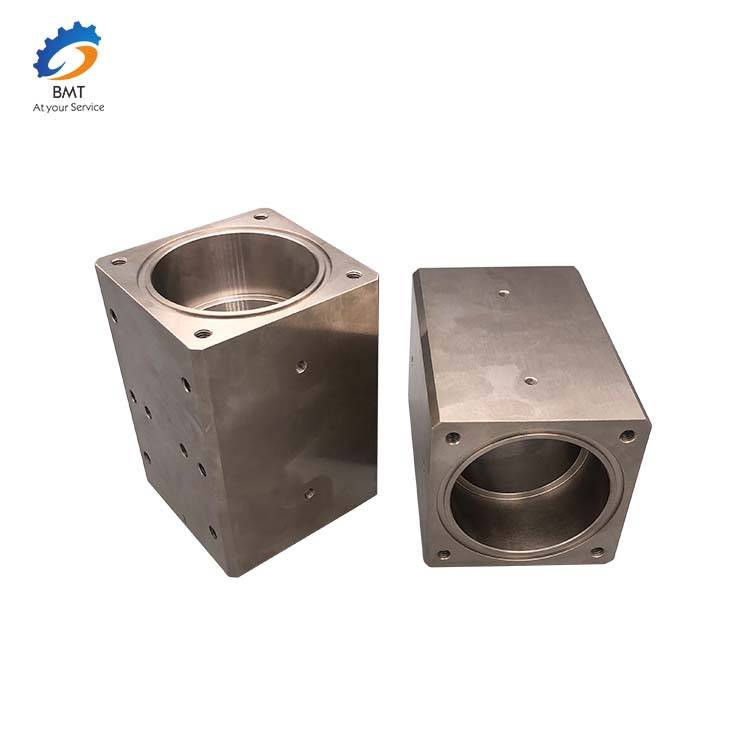

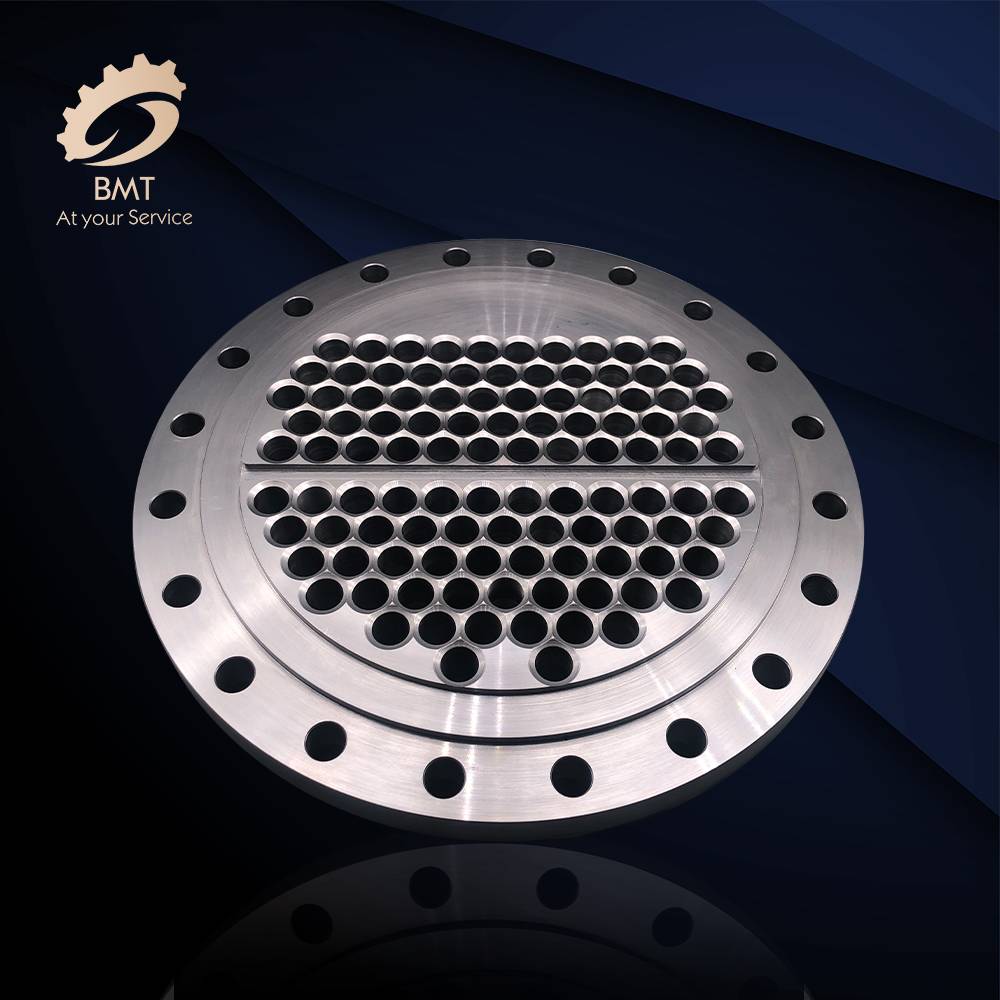

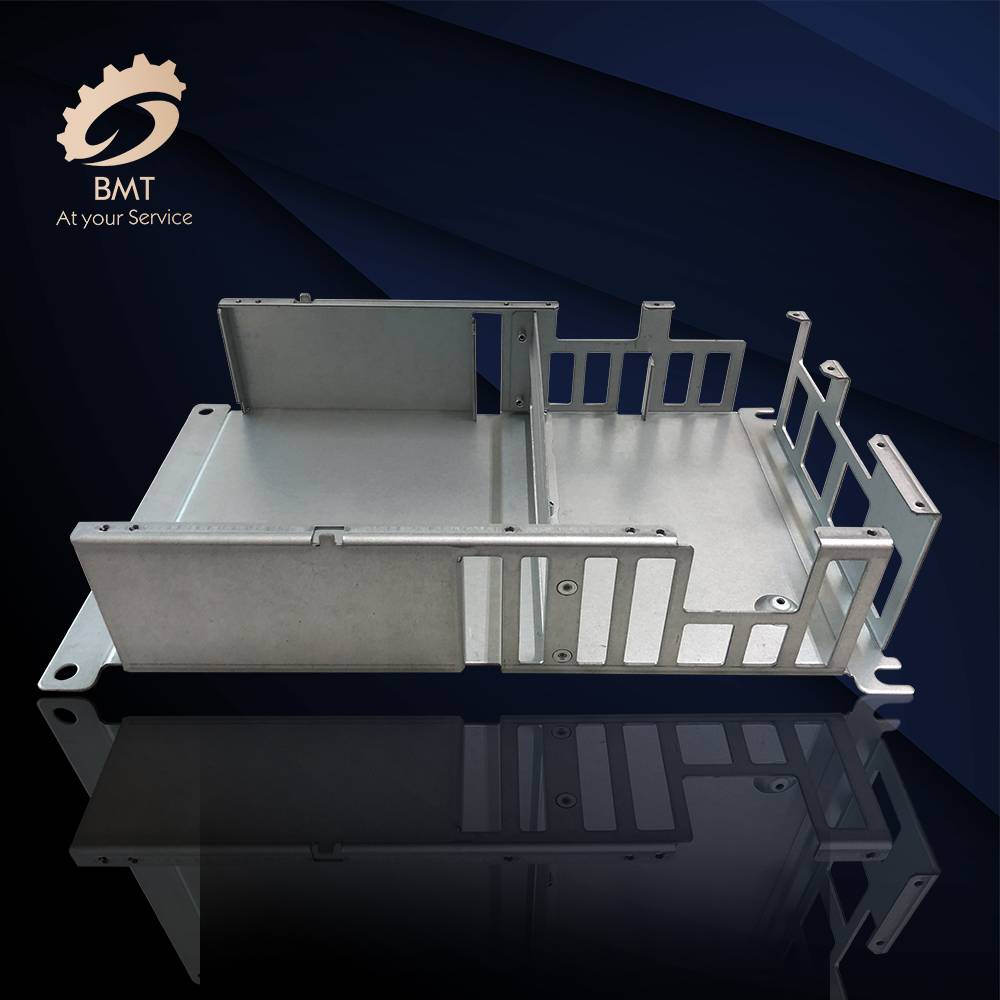

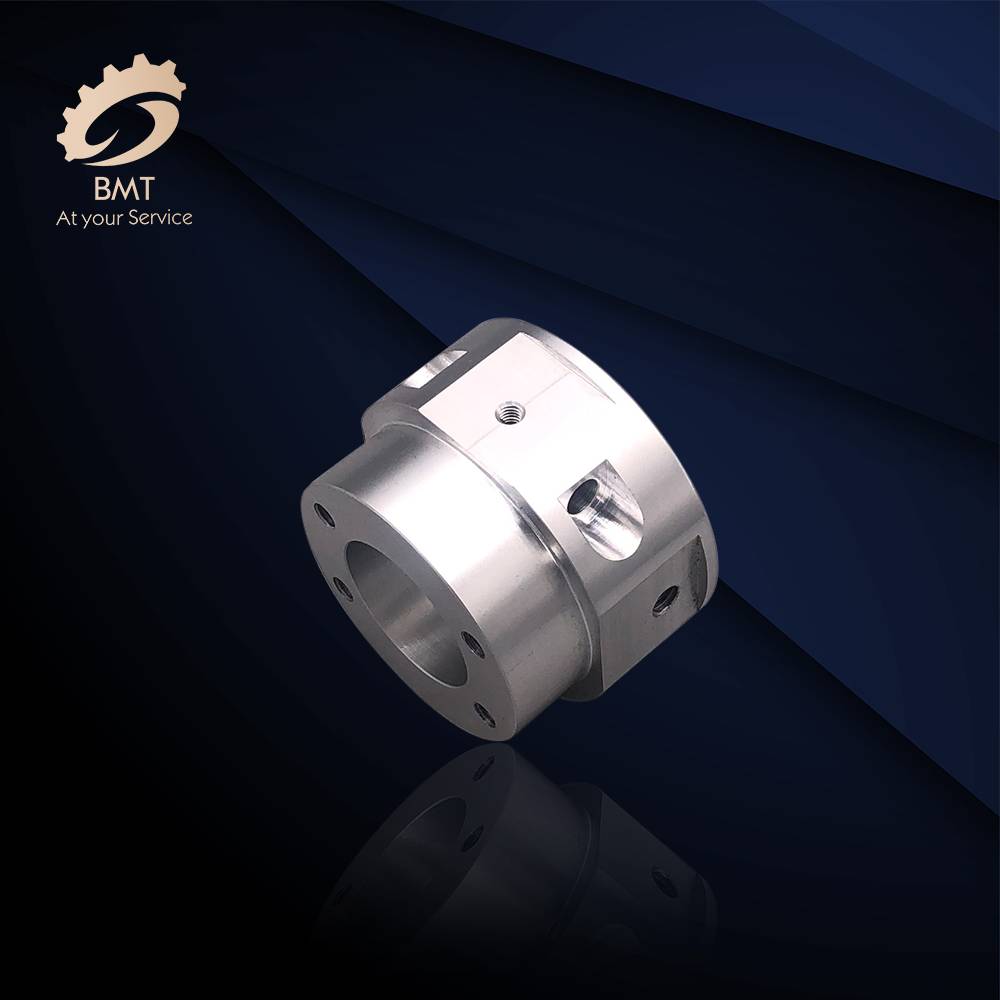

Precision Machining Parts

Precision Machining Parts

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Manufacturer of Stainless Steel Precision Cnc Machining - Mechanical Parts Machining – Basile, The product will supply to all over the world, such as: Guatemala, Auckland, Lesotho, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Send your message to us:

-

Excellent quality Stainless Sheet Metal Fabrica...

-

Competitive Price for Sierra Precision Machinin...

-

China OEM Metal Cnc Services - CNC Machined Co...

-

2021 High quality Auto Stamped Part - Sheet Me...

-

Competitive Price for Sierra Precision Machinin...

-

Hot sale Factory Cnc Build Parts - CNC Milling...