New Delivery for Cnc Precision Parts - Features of Milling Cutters 2 – Basile Detail:

Features of Milling Cutters

Trying to strengthen the rigidity of the fixture before processing starts will bring benefits to long-term production in the future. It not only prolongs the life of the tool, but also improves the surface quality of the workpiece and reduces the machining error.

Similarly, improper tool holder selection will shorten tool life. For example, if an end mill with a diameter of 3.175mm is installed in the cutter holder (instead of the spring chuck), due to the action of the tightening screw, the fitting gap between the cutter and the cutter holder is biased to one side, and the center of the cutter is deviated. The center of rotation of the tool holder increases the radial runout of the milling cutter during operation, resulting in an unbalanced cutting load on each tooth of the milling cutter. This cutting state is not good for the tool, especially when milling nickel-based alloys.

By using a tool holder that improves the eccentricity of tool mounting, such as hydraulic chuck and shrink-fit chuck, the cutting action can be more balanced and stable, the tool wear is reduced, and the surface quality is improved. A principle should be followed when choosing a handle, that is, the handle should be as short as possible. These tool and workpiece clamping requirements apply to milling any material, and when milling nickel-based alloys, advanced machining experience is required wherever possible.

Use of Tools

Regardless of how the tool is designed, or what material it is made of, the tool manufacturer should provide initial values for cutting speed and feed per tooth. If these data are not available, the manufacturer’s technical department should be consulted. Manufacturers should know how well their products are capable of full-width grooving, contouring, plunging, or ramping, since most of the standard milling cutters can’t handle this many operations. For example, if the milling cutter does not have a sufficiently large second clearance angle, the bevel angle for ramping is reduced.

Obviously, if the machining capacity of the tool is exceeded, it will cause damage to the tool. The same is true for plunge milling. If the chips cannot be expelled from the bottom of the groove in time, the chips will be squeezed and the tool will be damaged later. In conclusion, these conditions are detrimental to tool life when milling superalloys. If you thought slowing the feed rate would increase tool life, it turned out to be wrong. A typical example is when the first cut is made and the material is found to be quite hard. If the feed is reduced (for example, the feed per tooth of an indexable milling cutter is reduced to 0.025 to 0.5 mm), the cutting edge of the tool will strongly rub the workpiece, and the result will be that the tool will be damaged quickly or immediately. Friction can cause work hardening on the surface of the workpiece. In order to avoid work hardening, a certain cutting load (0.15-0.2mm/feed per tooth) should be maintained when cutting the first knife.

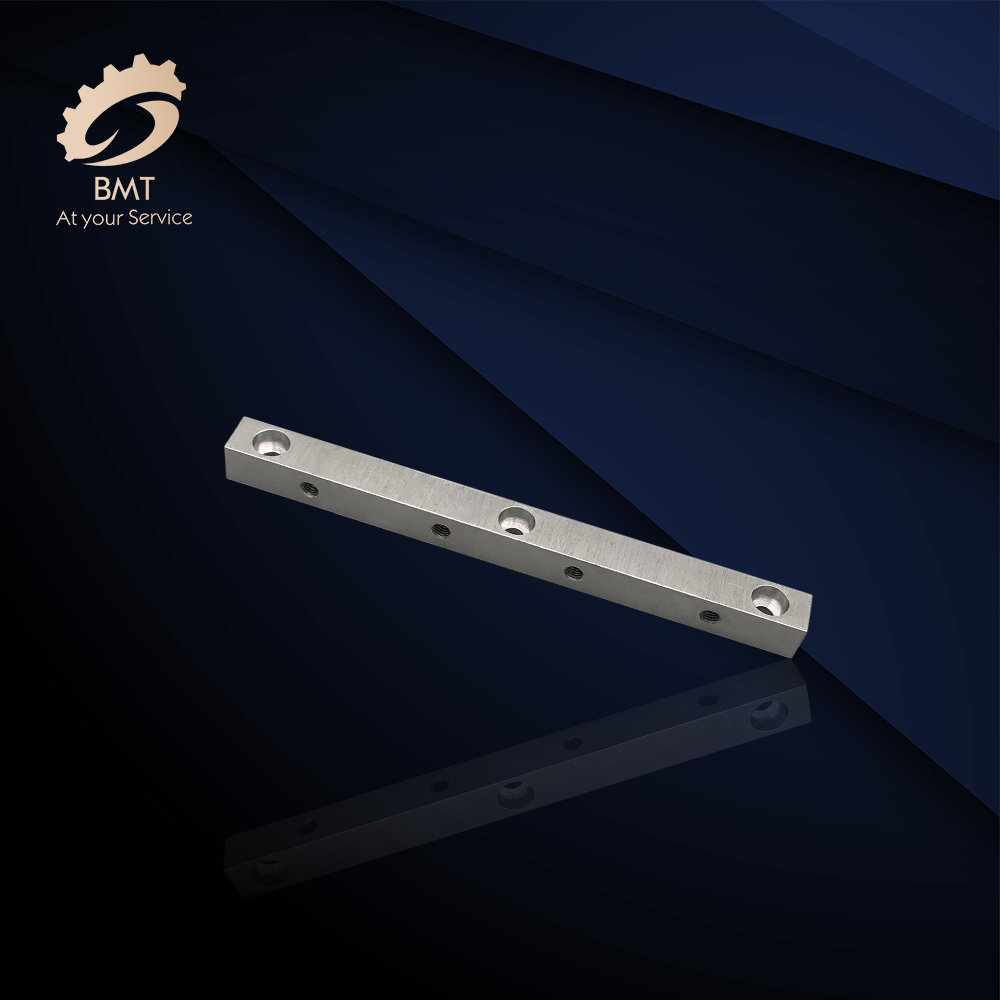

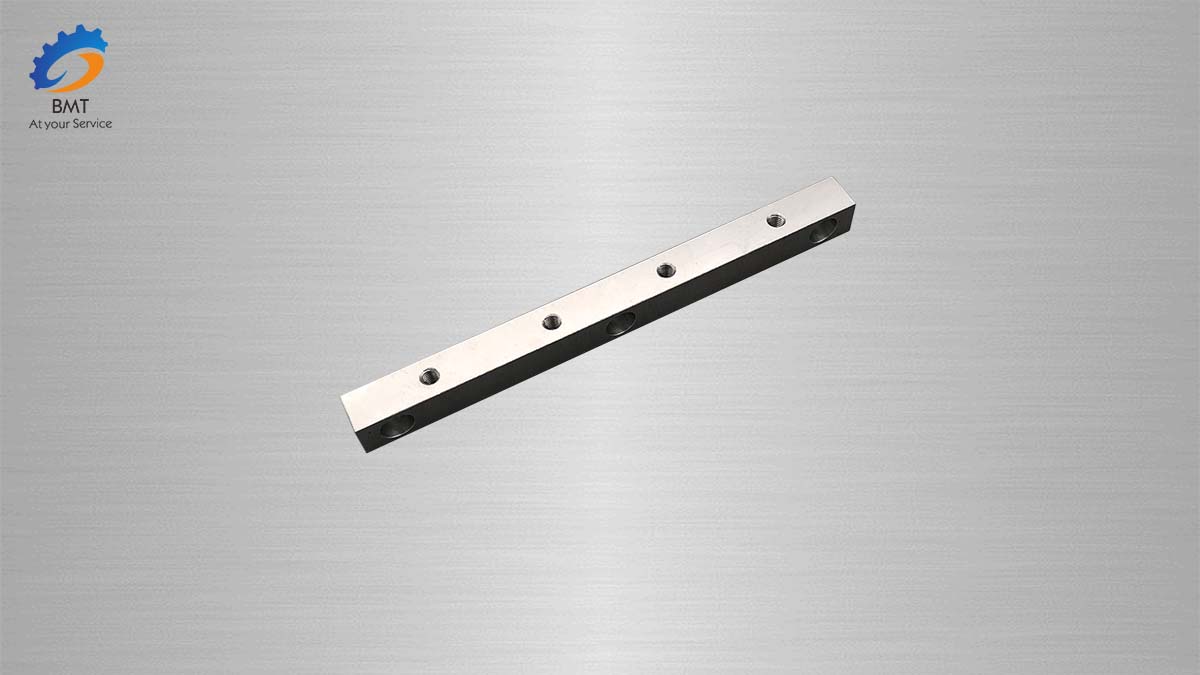

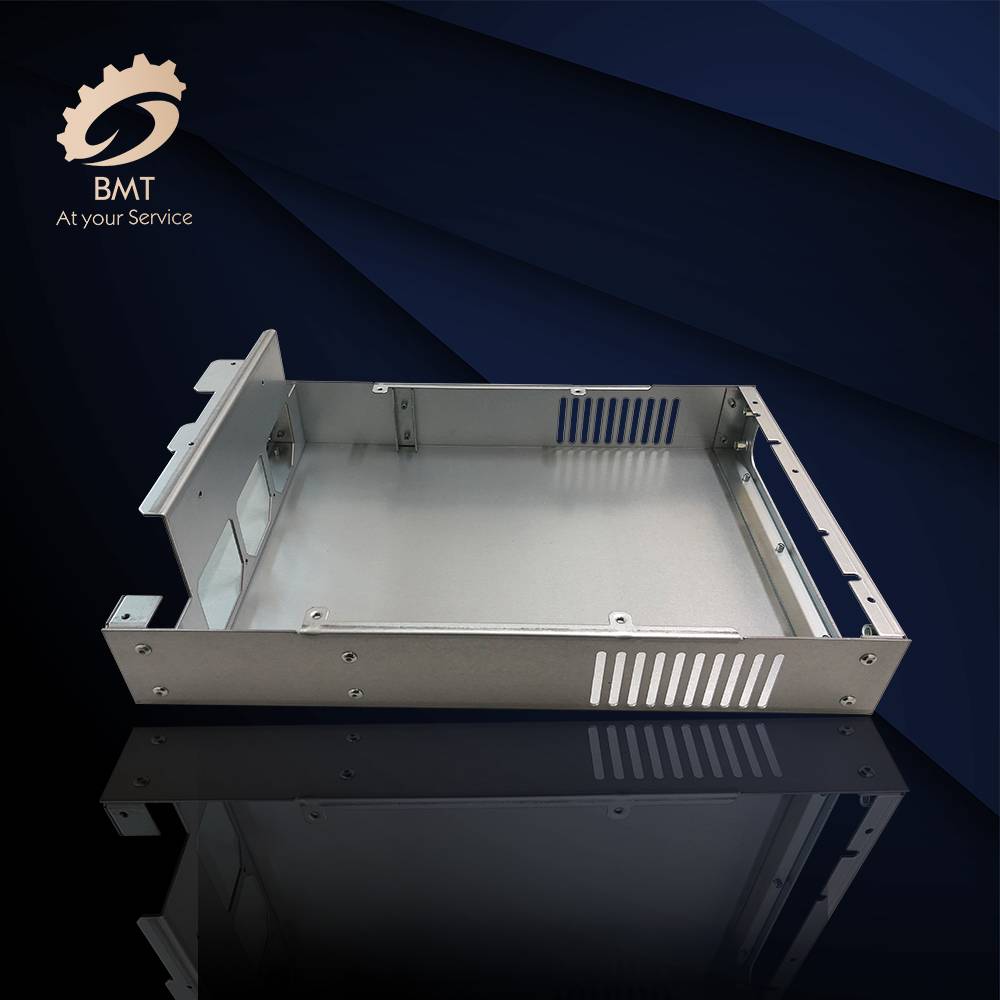

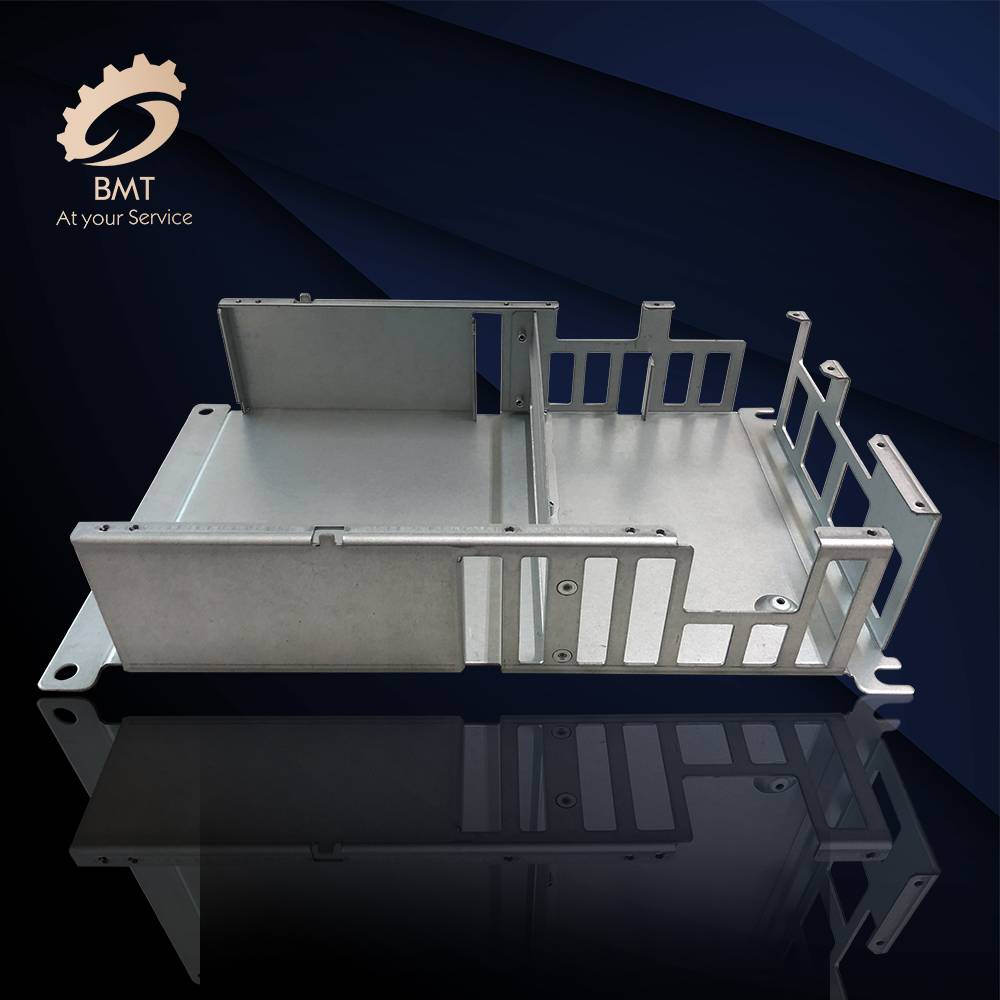

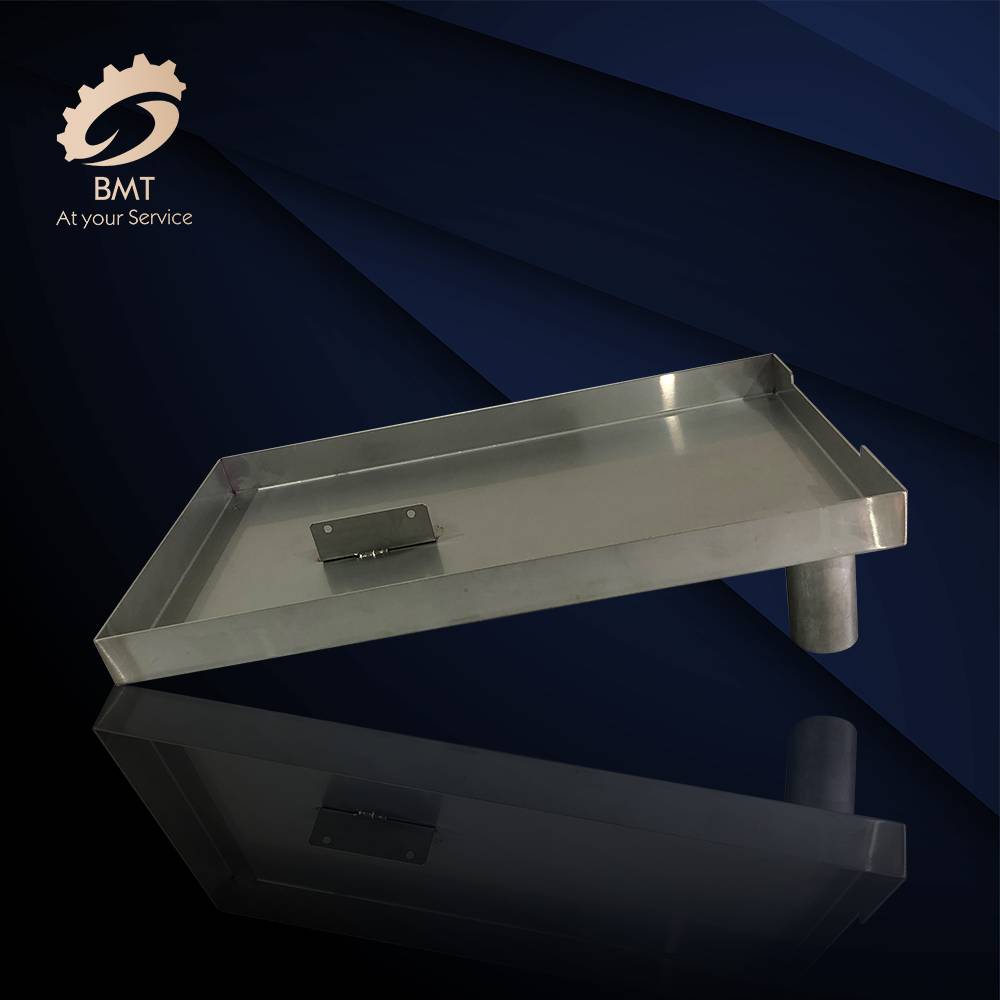

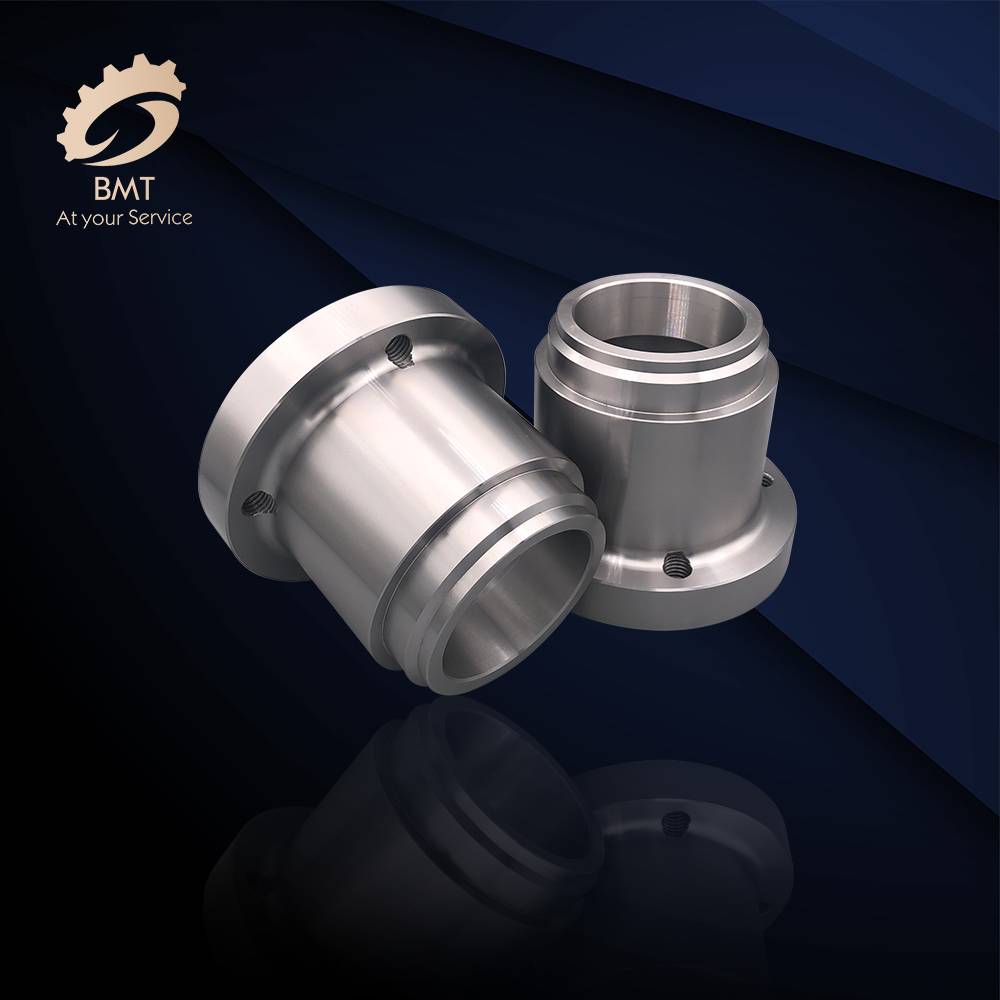

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for New Delivery for Cnc Precision Parts - Features of Milling Cutters 2 – Basile, The product will supply to all over the world, such as: Liberia, Plymouth, Algeria, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Send your message to us:

-

Competitive Price for Precision Sheet Metal Fab...

-

Factory Free sample Bending Stamping Part - Sh...

-

2021 China New Design Sheet Metal Fabrication B...

-

Hot New Products Cnc Milling Machine Components...

-

Bottom price Sheet Metal Panel Fabrication - P...

-

Good Quality Machining - F316L CNC Precision M...