Aluminum AL7075 is a high-strength alloy known for its exceptional mechanical properties, making it a popular choice for manufacturing precision parts and components. With its excellent strength-to-weight ratio, corrosion resistance, and machinability, AL7075 has become a preferred material for a wide range of applications, from aerospace and automotive to consumer electronics and sporting goods. The demand for aluminum AL7075 machining parts has been steadily increasing as industries seek lightweight yet durable solutions for their products. The aerospace industry, in particular, has embraced AL7075 for its ability to reduce overall weight without compromising structural integrity.

This has led to the development of advanced aircraft components, such as structural fittings, landing gear parts, and engine components, all of which benefit from the alloy's high strength and fatigue resistance. In the automotive sector, AL7075 machining parts are being used to create lightweight components that contribute to improved fuel efficiency and overall performance. From engine components to suspension systems, manufacturers are turning to AL7075 to reduce vehicle weight while maintaining the necessary strength and durability. The consumer electronics industry has also recognized the benefits of AL7075, utilizing the alloy to produce lightweight yet robust components for smartphones, laptops, and other portable devices.

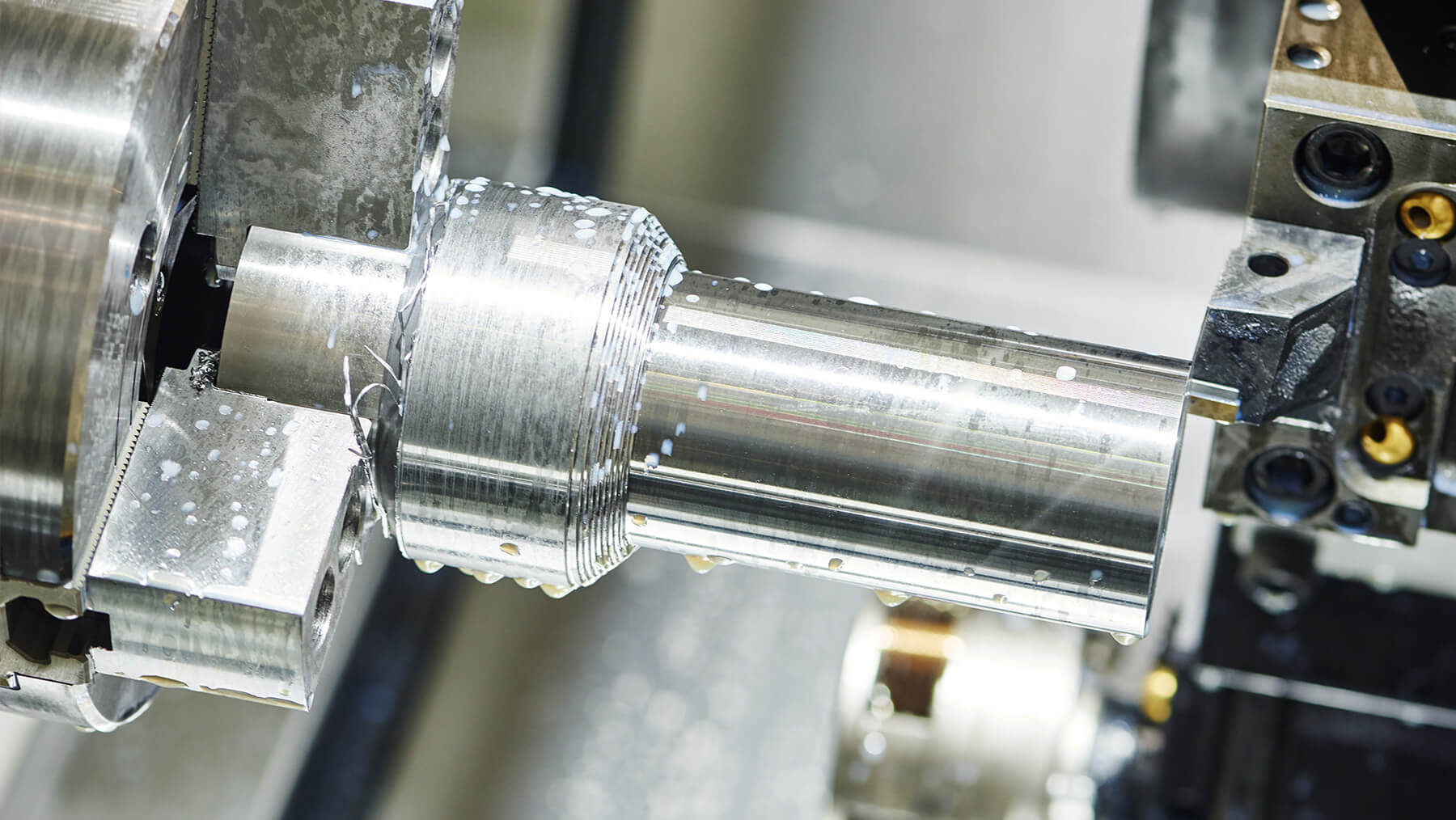

The use of AL7075 in these products not only enhances their durability but also contributes to a more sustainable approach by reducing the overall material consumption. In the sporting goods sector, AL7075 machining parts are being employed to create high-performance equipment, such as bicycle frames, golf club heads, and firearm components. The alloy's strength and lightweight properties make it an ideal choice for athletes and outdoor enthusiasts who seek durable and reliable gear. The increasing demand for AL7075 machining parts has also driven advancements in machining technology. Manufacturers are leveraging state-of-the-art CNC machining processes to produce complex and precise components from AL7075, ensuring that the alloy's inherent properties are fully realized in the final products.

Furthermore, the versatility of AL7075 allows for the creation of intricate and customized parts, catering to the specific needs of different industries. This flexibility has made AL7075 a go-to material for prototyping and low-volume production, enabling rapid development and iteration of new designs. As the demand for lightweight, durable, and high-performance components continues to grow across various industries, the role of aluminum AL7075 machining parts is poised to become even more significant. With ongoing research and development efforts focused on further enhancing the alloy's properties and processing techniques, the future looks promising for AL7075 as a material of choice for the next generation of advanced engineering solutions.

In conclusion, aluminum AL7075 machining parts represent the future of lightweight and durable components, offering a compelling combination of strength, weight savings, and versatility. As industries continue to push the boundaries of performance and efficiency, AL7075 is set to play a pivotal role in shaping the next wave of innovative products and technologies.

Post time: May-27-2024