Aluminum alloy machining parts have become an integral part of various industries due to their lightweight, durable, and versatile nature. These parts are widely used in automotive, aerospace, electronics, and other manufacturing sectors, where precision and reliability are crucial. The demand for aluminum alloy machining parts has been steadily increasing, driven by the need for high-performance components that offer a perfect balance of strength and weight. One of the key advantages of aluminum alloy machining parts is their exceptional strength-to-weight ratio. This makes them an ideal choice for applications where reducing weight without compromising structural integrity is essential. In the automotive industry, for example, the use of aluminum alloy machining parts has led to significant improvements in fuel efficiency and overall vehicle performance. Additionally, the aerospace industry has also embraced the use of aluminum alloy machining parts in aircraft construction, where every pound saved translates to increased payload capacity and reduced fuel consumption.

The versatility of aluminum alloy machining parts is another factor driving their widespread adoption. These parts can be machined into complex shapes and designs, allowing for the creation of custom components tailored to specific requirements. This flexibility makes aluminum alloy machining parts suitable for a wide range of applications, from engine components and structural elements to intricate electronic enclosures and heat sinks. Furthermore, aluminum alloy machining parts offer excellent corrosion resistance, making them suitable for use in harsh environments and outdoor applications. This property, combined with their high thermal conductivity, makes aluminum alloy machining parts an ideal choice for heat exchangers, cooling systems, and other thermal management solutions. As a result, these parts are increasingly being used in renewable energy systems, such as solar panels and wind turbines, where reliability and longevity are paramount.

The demand for aluminum alloy machining parts is also being driven by the growing trend towards sustainable and eco-friendly manufacturing practices. Aluminum is a highly recyclable material, and the production of aluminum alloy machining parts consumes significantly less energy compared to other metals. This makes aluminum alloy machining parts a preferred choice for companies looking to reduce their environmental impact and adhere to strict sustainability standards. In addition to their mechanical properties, aluminum alloy machining parts can also be surface-treated to enhance their performance and appearance. Anodizing, for example, can improve the corrosion resistance and wear characteristics of aluminum alloy parts, while also providing a decorative finish. This further expands the potential applications of aluminum alloy machining parts across various industries, where aesthetics and functionality go hand in hand.

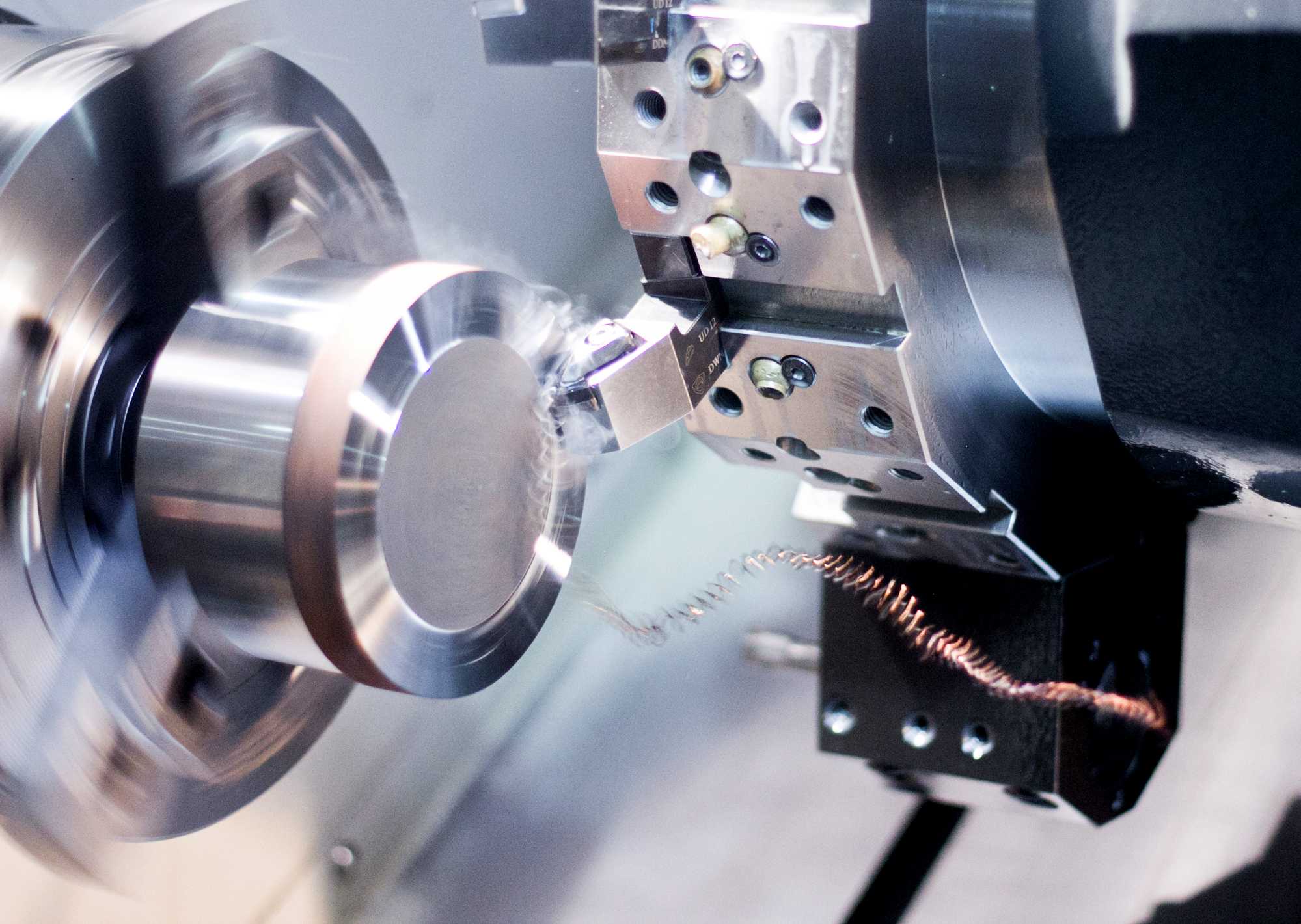

Looking ahead, the future of aluminum alloy machining parts appears promising, with ongoing advancements in material science and manufacturing technologies. The development of new aluminum alloys with enhanced properties, such as improved strength and formability, is opening up new possibilities for the use of aluminum alloy machining parts in demanding applications. Additionally, the adoption of advanced machining techniques, such as CNC machining and additive manufacturing, is enabling the production of highly complex and precise aluminum alloy parts with minimal material waste.

In conclusion, aluminum alloy machining parts have emerged as a cornerstone of modern manufacturing, offering a winning combination of lightweight construction, durability, and adaptability. As industries continue to prioritize performance, efficiency, and sustainability, the demand for aluminum alloy machining parts is expected to grow, driving innovation and pushing the boundaries of what is achievable with this versatile material. With ongoing research and development efforts, aluminum alloy machining parts are poised to play a pivotal role in shaping the future of engineering and design across a wide spectrum of industries.

Post time: Aug-26-2024