Aluminum sheet metal parts have become an integral component in a wide range of industries due to their versatility, durability, and lightweight properties. From aerospace and automotive to construction and electronics, the demand for aluminum sheet metal parts continues to grow as manufacturers seek high-quality, cost-effective solutions for their products. In the aerospace industry, aluminum sheet metal parts are highly sought after for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make them ideal for aircraft components, such as fuselage panels, wing skins, and structural elements. The use of aluminum sheet metal parts in aerospace applications not only contributes to fuel efficiency but also enhances the overall performance and safety of aircraft.

In the automotive sector, aluminum sheet metal parts play a crucial role in the production of lightweight vehicles that offer improved fuel efficiency and reduced emissions. From body panels and chassis components to heat exchangers and engine parts, aluminum sheet metal parts are widely utilized to achieve the desired balance between strength and weight. As the automotive industry continues to prioritize sustainability and energy efficiency, the demand for aluminum sheet metal parts is expected to rise further. The construction industry also benefits from the use of aluminum sheet metal parts, particularly in the fabrication of architectural elements, roofing systems, and structural components. The lightweight nature of aluminum makes it an attractive choice for construction projects, as it allows for easier handling, installation, and transportation. Additionally, the corrosion resistance of aluminum sheet metal parts ensures longevity and minimal maintenance, making them a cost-effective solution for various building applications. In the electronics sector, the demand for aluminum sheet metal parts is driven by the need for reliable, lightweight, and heat-dissipating components.

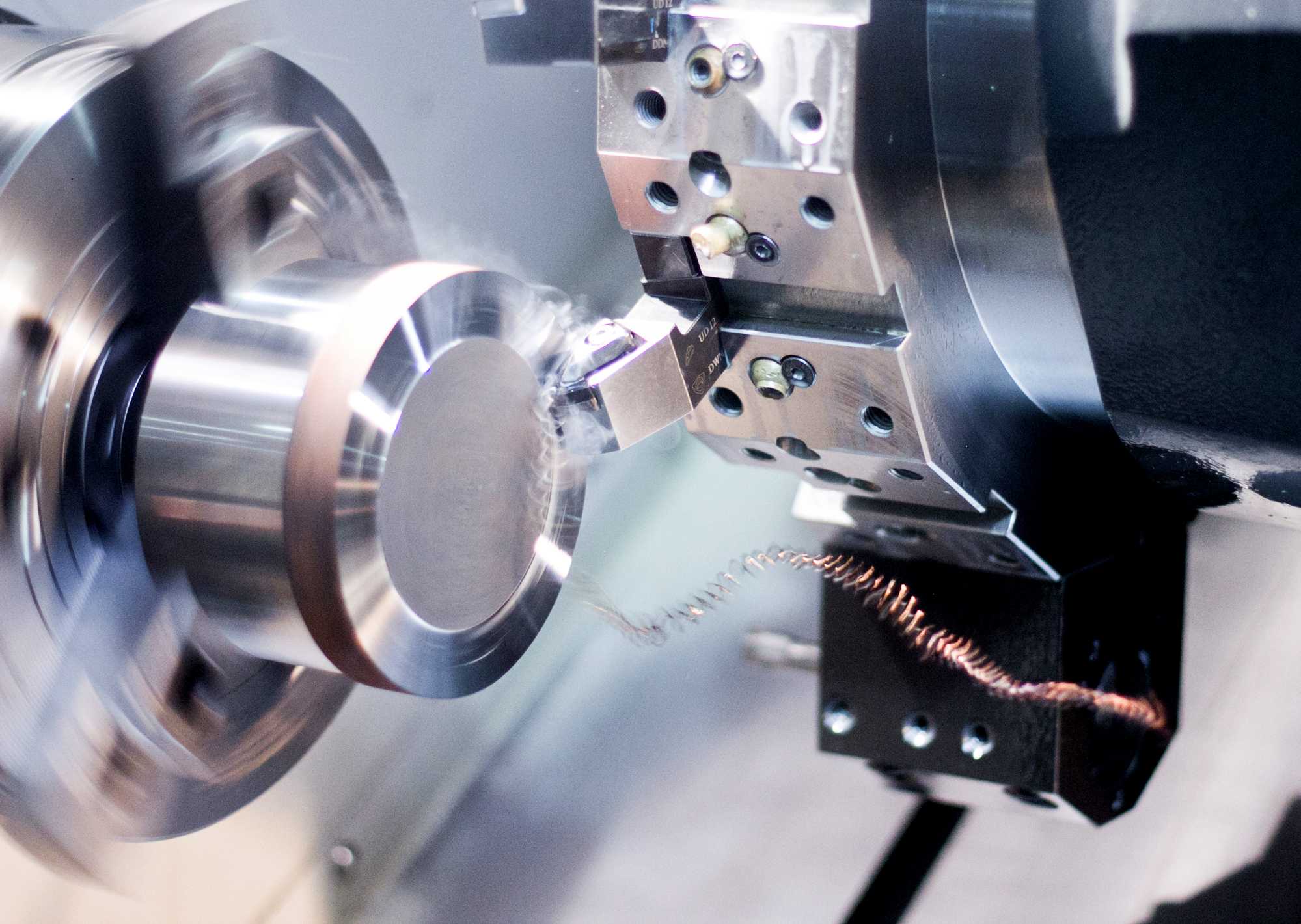

Aluminum's excellent thermal conductivity and electrical properties make it an ideal material for electronic enclosures, heat sinks, and other critical components that require efficient heat management and electromagnetic shielding. As the electronics industry continues to advance, the demand for precision-engineered aluminum sheet metal parts is expected to grow in tandem. The versatility of aluminum sheet metal parts extends beyond these industries, with applications in marine, renewable energy, consumer goods, and more. The ability to form, weld, and finish aluminum sheet metal parts to precise specifications makes them a preferred choice for manufacturers seeking high-performance solutions for their products. Furthermore, advancements in aluminum sheet metal fabrication technologies, such as laser cutting, CNC machining, and forming processes, have expanded the design possibilities and production capabilities of aluminum sheet metal parts.

This has led to the development of complex, lightweight, and intricately designed components that meet the stringent requirements of modern industries. As the global focus on sustainability and energy efficiency intensifies, the demand for aluminum sheet metal parts is expected to continue its upward trajectory. The recyclability of aluminum further enhances its appeal as a

In conclusion, the widespread adoption of aluminum sheet metal parts across diverse industries underscores their significance as a versatile, durable, and cost-effective solution for a wide range of applications. As technology and innovation drive the evolution of aluminum sheet metal fabrication, the potential for further advancements and new applications is vast, positioning aluminum sheet metal parts as a cornerstone of modern manufacturing and industrial development.

Post time: Jul-08-2024