BMT Capabilities

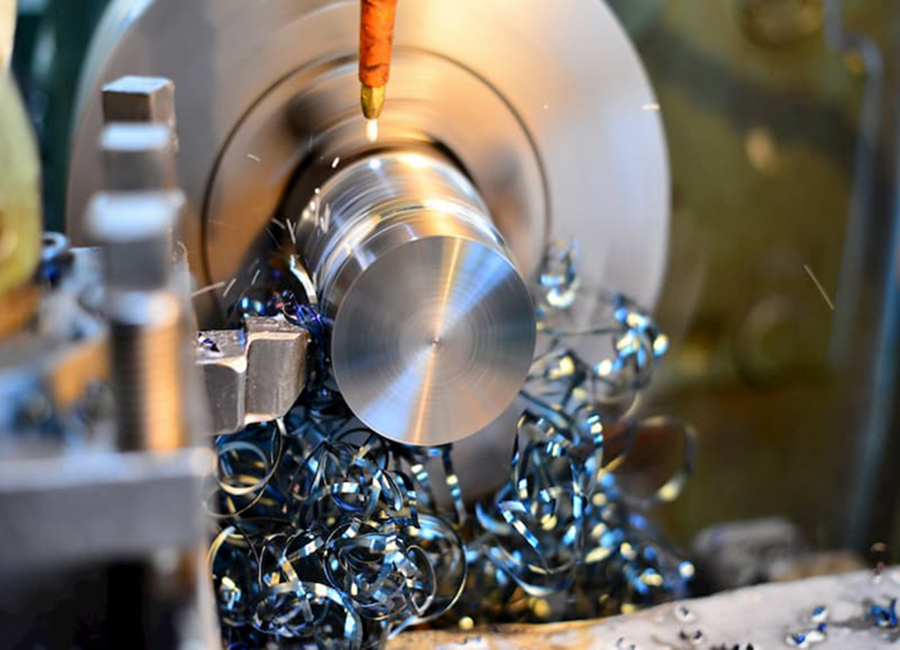

CNC (Computer Numerical Control) Machining is a form of manufacturing the parts and components made from materials such as metals, alloys and engineering plastics.

We are a reliable supplier of machined plastic and metal components. Here at BMT, we are able to supply prototype, single part and mass production parts. We fully and thoroughly understand the need to react quickly from initial enquiry through to delivery and after-sales service.

Here, We make a list for your reference, but what we can do is not limited with this. Our experience and skillful engineers provides you with one-stop service. What you need to do is to trust on us and give both of us an opportunity to work together and you will clearly know who we are and what we can provide. Welcome you all the time.

Materials and Surface Treatment

|

Who we are? |

Custom CNC Machining Parts |

|

Materials Available |

Aluminum: AL5052 / AL6061/ AL6063 / AL6082 / AL7075, etc. |

| Brass and Copper: C11000 / C12000 / C36000 / C37700 / 3602 / 2604 / H59 / H62, etc. | |

| Carbon Steel: A105, SA182 Gr70, Q235 / Q345 / 1020(C20) / 1025(C25) / 1035(C35) / 1045(C45), etc. | |

| Stainless Steel: SUS304 / SUS316L / SS201/ SS301/ SS3031 / 6MnR, etc. | |

| Alloy Steel: Alloy 59, F44/ F51/ F52/ F53/ F55/ F61, G35, Inconel 628/825, 904L, Monel, Hastelloy, etc. | |

| Mold Steel: 1.2510 / 1.2312 / 1.2316 / 1.1730, etc. | |

| Plastic: ABS/ Polycarbonate/ Nylon/ Delrin/ HDPE/ Polypropylene/ Clear Acrylic/ PVC/ Resin/ PE / PP / PS / POM, etc. | |

| Others materials: Casting and Forging Pars and As Customer’s request. | |

|

Surface Treatment |

Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Heat treatment, Powder Coated, etc. |

|

File Formats |

CAD, DXF, STEP, PDF, and other formats are acceptable. |

Machining Capacities

|

Services |

Custom, OEM, Design, etc. |

|

Process Type |

CNC Turning, Milling, Drilling, Grinding, Polishing, WEDM Cutting, Laser Engraving, etc. |

|

Tolerance |

0.002-0.01mm, this can also be customized. |

|

Roughness |

Ra0.4, Ra0.8, Ra1.6, Ra3.2, Ra6.3, etc., according to Customers’ Request. |

|

Turning Capacity |

Φ1~φ400*1500mm |

|

Milling Capacity |

1000*800*600 mm |

|

Drilling Capacity |

2-50mm |

|

Products Dimension |

As customers' request. |

|

Inspection Devices |

A. Mitutoyo Electronic Digital Display Caliper;

B. Mitutoyo OD Digimatic Micrometer; C. Mitutoyo Precision Block Gauge; D. Caliper Depth Rule and Go-no Go Gauge; E. Plug Gauge and R Gauge; F. ID Digimatic Micrometer; G. Thread Ring Gauge and Plug Gauge; H. Three Coordinate Measuring Machine; I. Angle Ruler and Meter Ruler; J. ID Gages and Microscope; K. Height Indicator and Dial Indicator; L. Inside Caliper and Dialgage; M. Projector Testing Machine; N. Levels of Marble Platform; |

Post time: Jan-10-2021