In recent years, the manufacturing industry has witnessed a significant shift towards digitization and automation. One particular advancement that has transformed the landscape of manufacturing is the utilization of Computer Numerical Control (CNC) machining services. This precision manufacturing technique has revolutionized the production process with its unparalleled accuracy, efficiency, and versatility. CNC machining involves the use of computer-controlled machine tools to shape and fabricate various materials into intricate components and parts. The process begins with creating a design using Computer-Aided Design (CAD) software, which is then transferred to the CNC machine using Computer-Aided Manufacturing (CAM) software. The machine can then follow the precise instructions provided by the software to carry out complex operations such as milling, drilling, cutting, and turning.

One of the primary advantages of CNC machining is its exceptional precision and repeatability. Unlike traditional manual machining methods, CNC machines can consistently produce components with tight tolerances and intricate geometries. This precision is especially critical in industries such as aerospace, automotive, and medical, where the smallest deviation can have significant consequences. Furthermore, CNC machining offers unmatched speed and efficiency. With automated tool changers and multi-axis capabilities, these machines can perform multiple operations simultaneously, greatly reducing production time. This not only increases productivity but also allows manufacturers to meet tight deadlines and deliver products to market faster. Moreover, CNC machining services provide an unparalleled level of versatility.

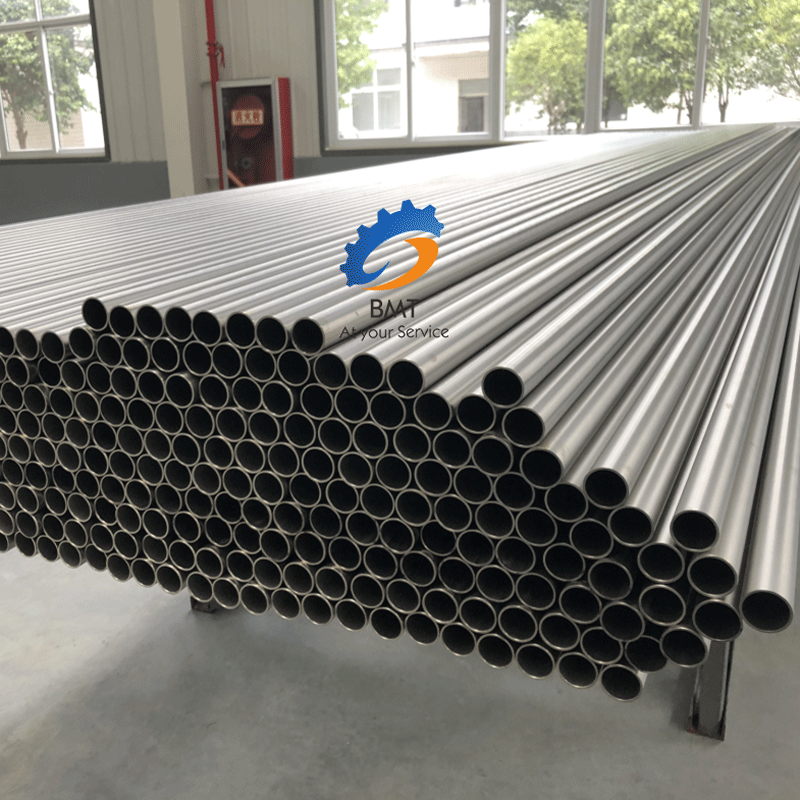

These machines can work with a wide range of materials such as metals, plastics, composites, and even wood. This flexibility enables manufacturers to cater to diverse customer requirements and adapt to shifting market demands. From small, intricate parts to large-scale structures, CNC machining can handle various sizes and complexities, offering a comprehensive solution for manufacturing needs. The integration of CNC machining services has had a profound impact on the manufacturing industry, leading to increased competitiveness and profitability. Small and medium-sized enterprises (SMEs), in particular, have benefited from this technology, as it has levelled the playing field against larger competitors.

Previously, SMEs had limited access to advanced manufacturing techniques due to their high costs. However, with the advent of CNC machining services, these smaller businesses can now produce high-quality components at a fraction of the cost, enabling them to expand their customer base and improve profitability. Additionally, CNC machining services have paved the way for innovation and product development. The use of advanced CAD/CAM software allows manufacturers to iterate and refine their designs quickly. This capability, coupled with the flexibility of CNC machines, encourages experimentation and facilitates rapid prototyping. As a result, businesses can bring new products to market faster, stay ahead of the competition, and meet evolving customer demands. Looking ahead, the future of CNC machining services appears promising. Technological advancements are continuously driving improvements in machine capabilities, enabling even higher levels of precision and efficiency.

Furthermore, the integration of artificial intelligence and machine learning algorithms into CNC machines holds the potential to further streamline operations and enhance productivity. In conclusion, CNC machining services have become an indispensable tool in the manufacturing industry. The combination of precision, speed, versatility, and cost-effectiveness makes this technology a game-changer for businesses across various sectors. As the industry continues to embrace digitization and automation, the demand for CNC machining services is expected to soar, contributing to the growth and success of the manufacturing sector in the years to come.

Post time: Sep-11-2023