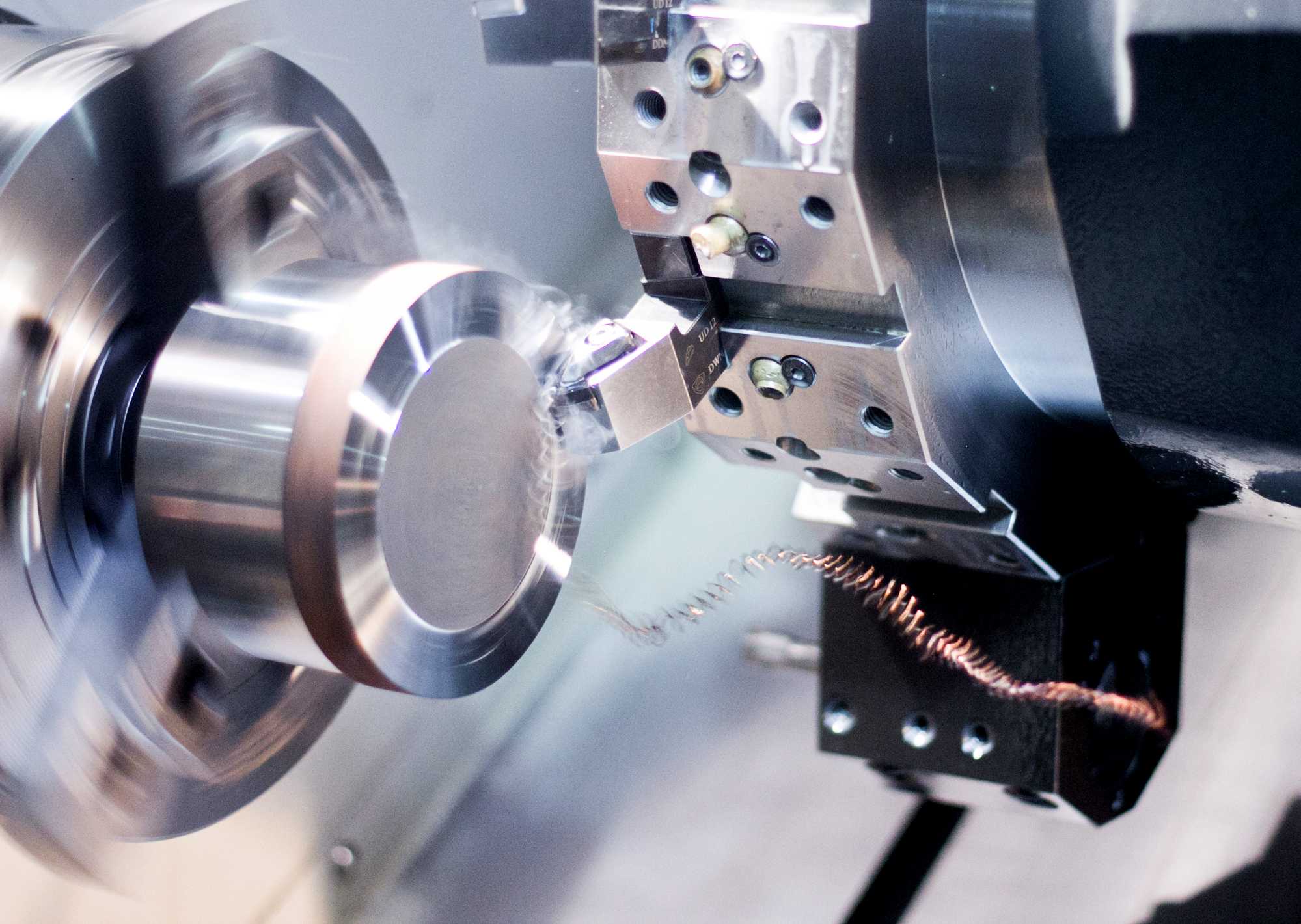

In the world of manufacturing, CNC machining spare parts play a crucial role in ensuring the smooth and efficient operation of various industries. From automotive to aerospace, medical devices to consumer electronics, CNC machining spare parts are the backbone of modern manufacturing processes. CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece, creating custom-designed parts with high precision and accuracy. These parts are essential components of machinery and equipment used in a wide range of industries.

One of the key advantages of CNC machining spare parts is their ability to be produced with a high level of consistency and repeatability. This is particularly important in industries where precision and quality are paramount, such as aerospace and medical device manufacturing. CNC machining spare parts can be manufactured to very tight tolerances, ensuring that they meet the exact specifications required for their intended application. Furthermore, CNC machining spare parts can be produced from a wide variety of materials, including metals, plastics, and composites. This versatility allows manufacturers to create parts that are tailored to the specific needs of their products, whether it's a lightweight component for an aircraft or a durable part for a heavy-duty industrial machine.

The automotive industry is one of the largest consumers of CNC machining spare parts. From engine components to transmission parts, CNC machining plays a critical role in the production of high-performance and reliable vehicles. The precision and consistency of CNC machining spare parts are essential for ensuring the safety and performance of modern automobiles. In the aerospace industry, CNC machining spare parts are used in the production of aircraft components, such as turbine blades, landing gear, and structural elements. These parts must meet stringent quality and safety standards, and CNC machining allows for the production of complex and intricate components with the highest level of precision.

The medical device industry also relies heavily on CNC machining spare parts for the production of surgical instruments, implants, and diagnostic equipment. The ability to create custom-designed parts with exceptional accuracy is essential for ensuring the effectiveness and safety of medical devices used in patient care. In the consumer electronics sector, CNC machining spare parts are used in the production of components for smartphones, laptops, and other electronic devices. The demand for smaller, lighter, and more durable parts has driven the use of CNC machining to create intricate and high-precision components for these products.

Overall, CNC machining spare parts are an indispensable part of modern manufacturing, enabling the production of high-quality, custom-designed components for a wide range of industries. As technology continues to advance, CNC machining will play an increasingly vital role in meeting the evolving needs of manufacturing and driving innovation in various sectors.

Post time: Jul-15-2024