In a groundbreaking development, researchers have made significant strides in the field of materials science by creating a new alloy that combines the unique Properties Of Inconel And Titanium. This innovative material has the potential to revolutionize various industries, from aerospace to medical devices, due to its exceptional strength, corrosion resistance, and lightweight nature. Inconel, a family of austenitic nickel-chromium-based superalloys, is renowned for its high temperature resistance and excellent mechanical properties. It is commonly used in extreme environments, such as gas turbine components, due to its ability to withstand high levels of heat and stress. On the other hand, titanium is known for its exceptional strength-to-weight ratio, making it an ideal choice for aerospace applications and medical implants.

By combining the strengths of these two materials, researchers have created a new alloy that offers a unique set of properties. The alloy exhibits high strength and toughness, making it suitable for applications where durability and reliability are paramount. Additionally, its corrosion resistance makes it an attractive option for use in harsh environments, such as marine and chemical processing industries. One of the most promising aspects of this new alloy is its potential impact on the aerospace industry. With its high strength and lightweight nature, the alloy could lead to the development of more fuel-efficient aircraft and spacecraft. This could have far-reaching implications for the aviation industry, as it strives to reduce carbon emissions and improve overall efficiency.

Furthermore, the medical field stands to benefit from this new alloy as well. The combination of strength, corrosion resistance, and biocompatibility makes it an ideal candidate for medical implants and devices. This could lead to improved patient outcomes and a wider range of treatment options for various medical conditions. The automotive industry is also likely to take notice of this new alloy, as it offers the potential for lighter, more durable components that could improve fuel efficiency and overall performance. Additionally, the alloy's resistance to corrosion could make it an attractive option for use in automotive exhaust systems and other components exposed to harsh environmental conditions.

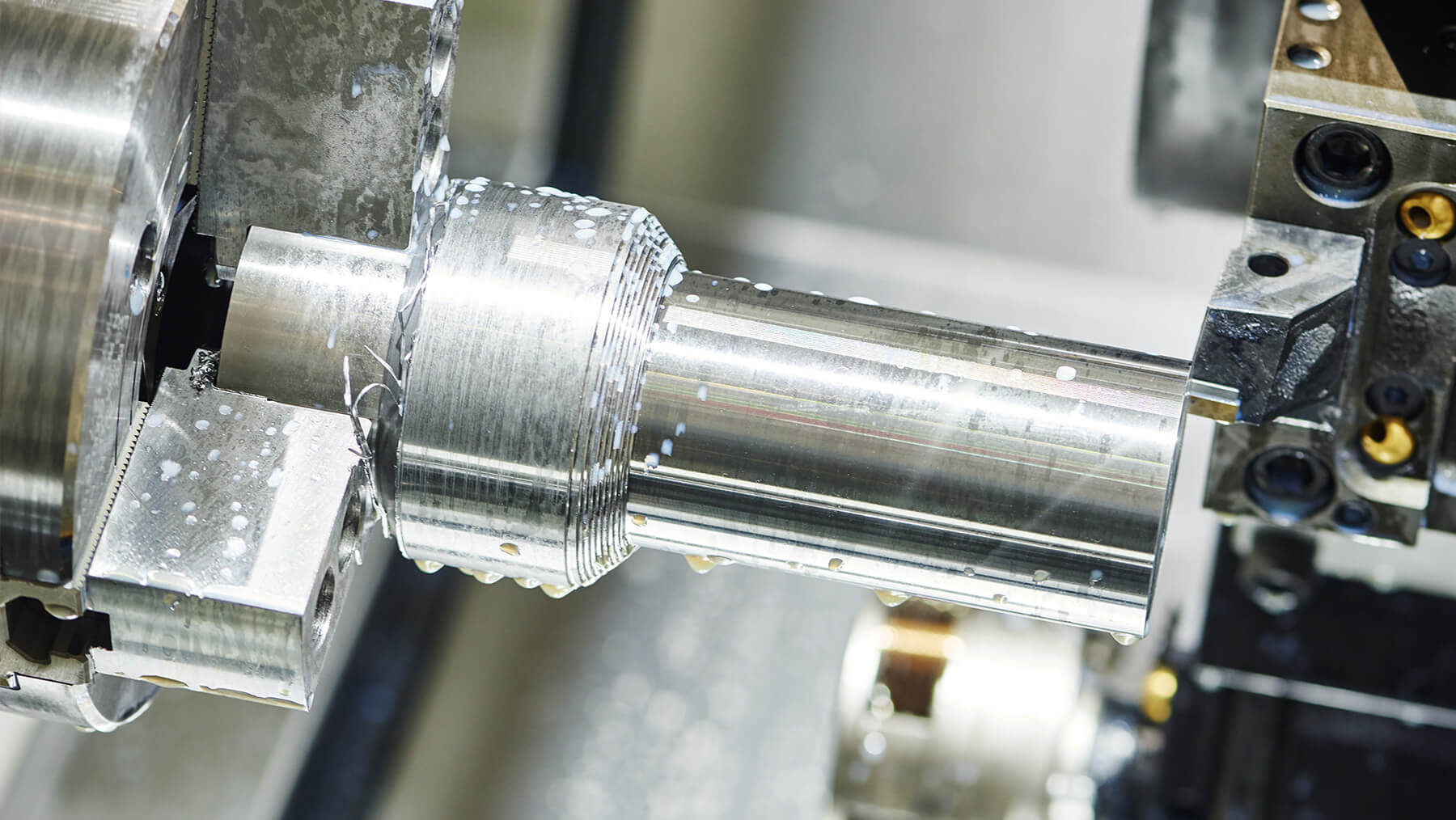

In the realm of manufacturing, the new alloy could lead to the development of more durable and efficient equipment for various industrial processes. Its high temperature resistance and strength make it an ideal candidate for use in machinery and tools that operate in extreme conditions. The development of this new alloy represents a significant advancement in materials science and has the potential to impact a wide range of industries. As researchers continue to explore the possibilities of this innovative material, it is likely that new applications and uses will emerge, further solidifying its place as a game-changing material in the world of engineering and manufacturing.

In conclusion, the creation of a new alloy that combines the unique properties of Inconel and titanium represents a major breakthrough in materials science. With its exceptional strength, corrosion resistance, and lightweight nature, this innovative material has the potential to revolutionize industries ranging from aerospace to medical devices. As researchers continue to explore its capabilities, the possibilities for this new alloy are truly limitless, and its impact on various sectors is likely to be profound.

Post time: May-13-2024