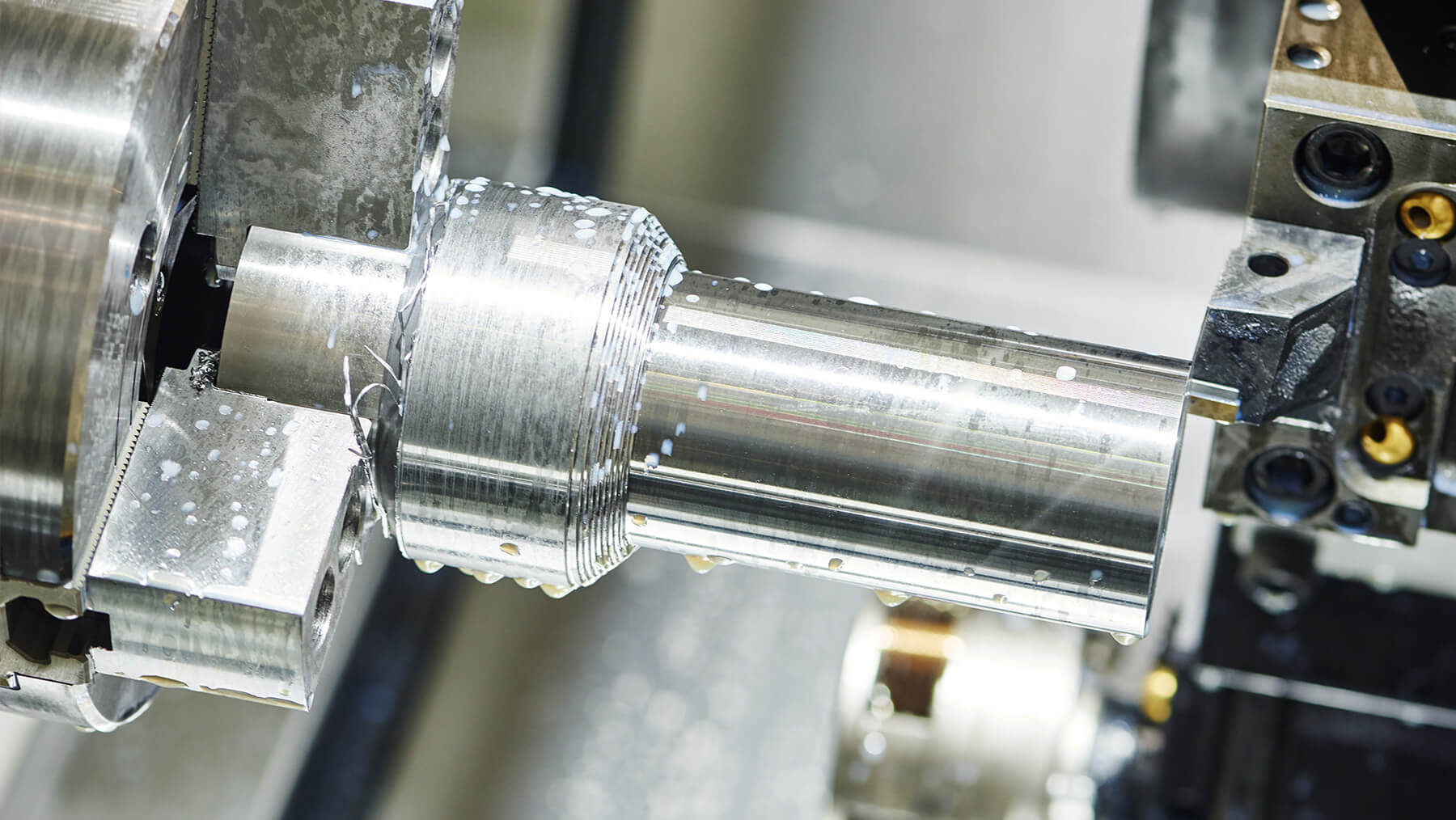

In the ever-evolving world of automotive manufacturing, custom CNC machining has become an indispensable tool for creating precision parts and components. The auto industry relies heavily on CNC machining to produce high-quality, complex parts that meet the stringent demands of modern vehicles. From engine components to intricate interior details, CNC machining plays a crucial role in shaping the future of automotive technology. CNC (Computer Numerical Control) machining involves the use of computer-controlled machines to precisely cut and shape materials such as metal, plastic, and composites. This technology allows for the creation of intricate and complex parts with unparalleled accuracy and consistency. In the auto industry, where precision and reliability are paramount, CNC machining has become a cornerstone of the manufacturing process.

One of the key advantages of custom CNC machining in the auto industry is its ability to produce parts with tight tolerances and intricate geometries. This level of precision is essential for ensuring that components fit together seamlessly, leading to improved performance and durability in vehicles. Whether it's the intricate design of an engine block or the precise shaping of transmission components, CNC machining enables manufacturers to create parts that meet the exact specifications required for modern automotive applications. Furthermore, custom CNC machining allows for the production of parts in a wide range of materials, including aluminum, steel, titanium, and various engineering plastics. This versatility is crucial for meeting the diverse needs of the auto industry, where different components require different materials to achieve optimal performance and longevity.

CNC machining provides the flexibility to work with a variety of materials, ensuring that manufacturers can produce parts that are tailored to the specific requirements of each vehicle. In addition to precision and material versatility, custom CNC machining also offers efficiency and cost-effectiveness in the production of auto parts. By automating the manufacturing process and minimizing human intervention, CNC machining reduces the risk of errors and inconsistencies, leading to higher quality and reliability in the finished products. This level of efficiency not only streamlines the production process but also helps to control costs, making CNC machining an attractive option for automotive manufacturers looking to optimize their operations.

Moreover, the use of custom CNC machining in the auto industry has also opened up new possibilities for innovation and design. With the ability to create complex and intricate parts, designers and engineers have the freedom to push the boundaries of automotive technology, leading to advancements in performance, safety, and efficiency. From lightweight, high-strength components to intricately designed interior features, CNC machining has empowered the auto industry to explore new frontiers in vehicle design and functionality. As the automotive industry continues to evolve, the demand for custom CNC machining is expected to grow even further. With the need for precision, efficiency, and innovation driving the development of next-generation vehicles, CNC machining will remain a critical tool for meeting these demands.

From traditional automakers to emerging electric vehicle manufacturers, custom CNC machining will continue to play a pivotal role in shaping the future of the auto industry. In conclusion, custom CNC machining has become an indispensable asset for the auto industry, providing the precision, versatility, efficiency, and innovation needed to drive the advancement of modern vehicles. As technology continues to progress, CNC machining will undoubtedly remain a cornerstone of automotive manufacturing, enabling manufacturers to create the high-quality, complex parts required for the vehicles of tomorrow.

Post time: Jun-03-2024