There are two kinds of titanium ore on earth, one is rutile and the other is ilmenite. Rutile is basically a pure mineral containing more than 90% titanium dioxide, and the content of iron and carbon in ilmenite is basically half and half.

At present, the industrial method for preparing titanium is to replace the oxygen atoms in titanium dioxide with chlorine gas to make titanium chloride, and then use magnesium as a reducing agent to reduce titanium. The titanium produced in this way is sponge-like, also called sponge titanium.

Titanium sponge can only be made into titanium ingots and titanium plates for industrial use after two smelting processes. Therefore, although the content of titanium ranks ninth on the earth, the processing and refining are very complicated, so its price is also high.

At present, the country with the most abundant titanium resources in the world is Australia, followed by China. In addition, Russia, India and the United States also have abundant titanium resources. But China's titanium ore is not of high grade, so it still needs to be imported in large quantities.

Titanium industry, the glory of the Soviet Union

In 1954, the Council of Ministers of the Soviet Union made a decision to create a titanium industry, and in 1955, a thousand-ton VSMPO magnesium-titanium factory was built. In 1957, VSMPO merged with AVISMA aviation equipment factory and established the VSMPO-AVISMA titanium industry consortium, which is the famous Avi Sima Titanium. The titanium industry of the former Soviet Union has been in a leading position in the world since its establishment, and has been fully inherited by Russia until now.

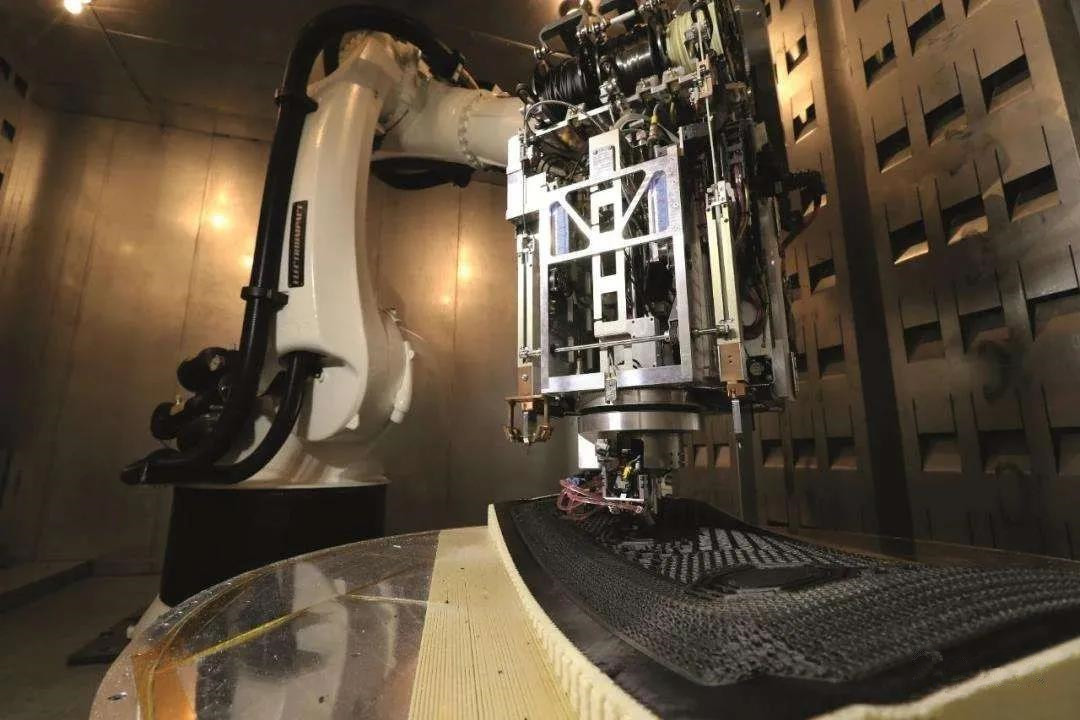

Avisma Titanium is currently the world's largest, fully industrial process titanium alloy processing body. It is an integrated enterprise from the smelting of raw materials to finished titanium materials, as well as the manufacture of large-scale titanium parts. Titanium is harder than steel, but its thermal conductivity is only 1/4 that of steel and 1/16 of that of aluminum. In the process of cutting, the heat is not easy to dissipate, and it is very unfriendly to tools and processing equipment. Usually, titanium alloys are made by adding other trace elements to titanium to meet various requirements.

According to the characteristics of titanium, the former Soviet Union made three kinds of titanium alloys for different purposes. One is for processing plates, one is for processing parts, and the other is for processing pipes. According to different uses, Russian titanium materials are divided into 490MPa, 580MPa, 680MPa, 780MPa strength grades. At present, 40% of Boeing's titanium parts and more than 60% of Airbus' titanium materials are supplied by Russia.

Post time: Jan-24-2022