During the former Soviet Union, due to the large output and good quality of titanium, a large number of them were used to build submarine pressure hulls. Typhoon-class nuclear submarines used 9,000 tons of titanium. Only the former Soviet Union was willing to use titanium to build submarines, and even built all-titanium submarines, which are the famous Alpha-class nuclear submarines. A total of 7 Alpha-class nuclear submarines have been built, which once set a world record of diving 1 km and a speed of 40 knots, which has not been broken so far.

Titanium material is very active and can easily catch fire at high temperatures, so it cannot be welded by the usual methods. All titanium materials need to be welded under inert gas protection. The former Soviet Union built large inert gas shielded welding chambers, but the power consumption was very large. It is said that welding the skeleton of Figure 160 once consumes the electricity of a small city.

The titanium shell of China's Jiaolong submersible is made in Russia.

China Titanium Industry

Only China, Russia, the United States and Japan have all-titanium technological processes. These four countries can complete one-stop processing from raw materials to finished products, but Russia is the strongest.

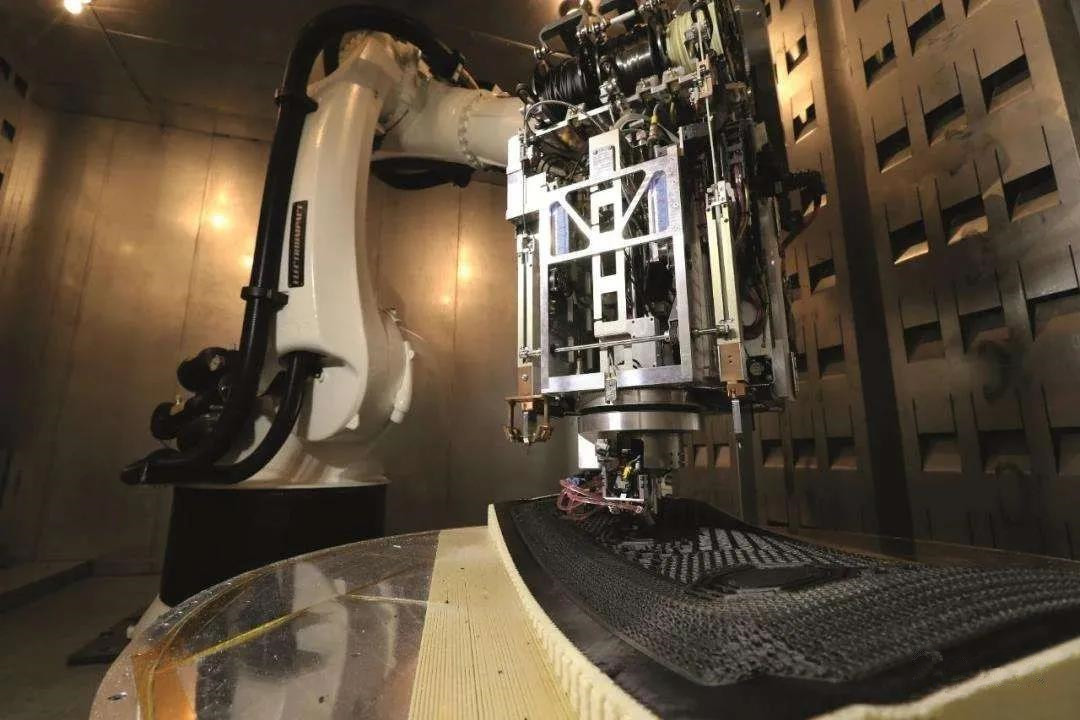

In terms of output, China is the world's largest manufacturer of titanium sponge and titanium sheets. There is still a gap between China and the world's advanced level in manufacturing large-scale titanium parts by traditional cold bending, turning, welding and other processes. However, China has taken a different approach to overtaking on bends, directly using 3D printing technology to manufacture parts.

At present, my country is at the leading level in the world in terms of 3D printing titanium materials. The main titanium alloy load-bearing frame of the J-20 is printed with 3D titanium. In theory, 3D printing technology can manufacture the load-bearing structure of Figure 160, but it may still require traditional processes to manufacture super-large titanium structures such as submarines.

At this stage, titanium alloy materials have gradually become the main raw materials for large-scale precision castings. In order to effectively solve large-scale precision castings of titanium alloy materials, the process of CNC machining is complicated, the processing deformation is difficult to control, the local rigidity of the casting is poor, and local characteristics Due to the actual production problems such as high processing difficulty, it is necessary to study from the aspects of allowance detection, positioning method, process equipment, etc., and design targeted optimization strategies to improve the CNC machining mechanism of titanium alloy castings.

Post time: Feb-01-2022