Under the Covid-19 situation, BMT still insists to provide high quality CNC Machining products to our customers. So, now, let us discuss the production process.

The production process of the machine refers to the whole process of making products from raw materials (or semi-finished products).In terms of machine production, it includes transportation and storage of raw materials, preparation for production, manufacture of blank, processing and heat treatment of parts, assembly and debugging of products, painting and packaging, etc.The content of production process is very extensive. Modern enterprises use the principles and methods of system engineering to organize production and guide production, and regard the production process as a production system with input and output.

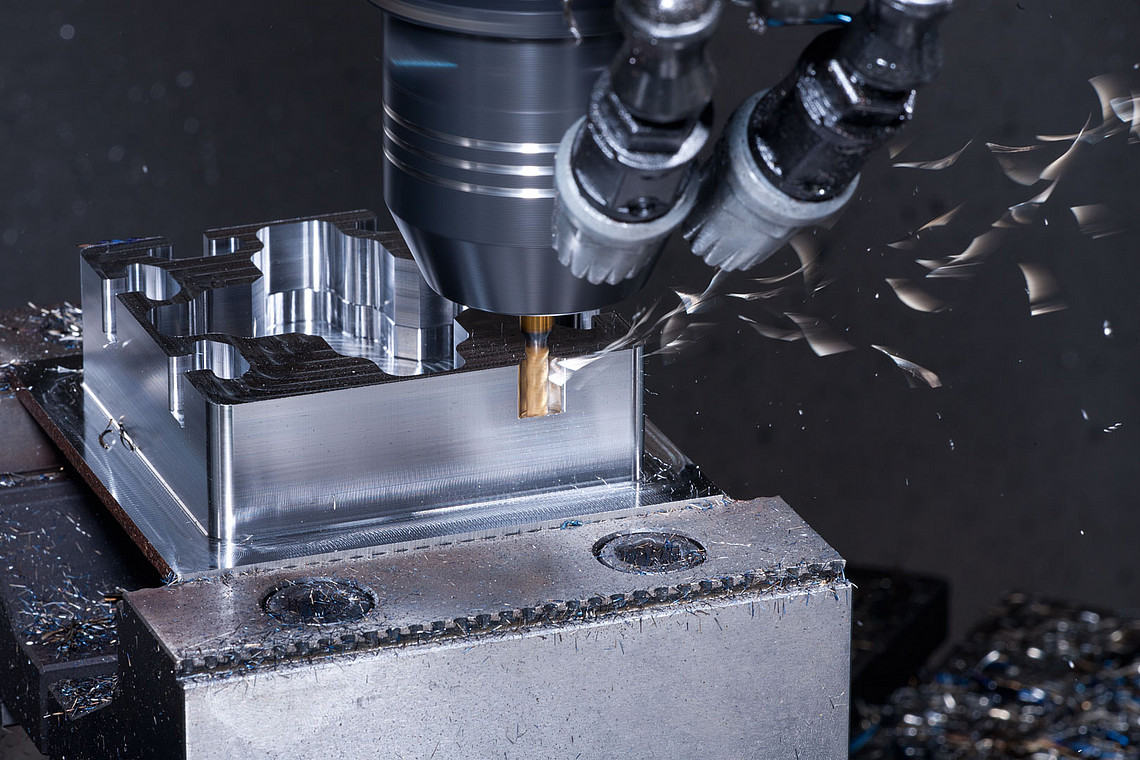

In the process of production, the process of changing the shape, size, position and nature of the production object to make it into finished products or semi-finished products is called technological process.It is an essential part of the production process.Process: casting, forging, stamping, welding, machining, assembly processes, such as machinery manufacturing process generally refers to the part machining process and machine of the sum of the assembly process, other process is known as the auxiliary process, such as transportation, storage, power supply, equipment maintenance, etc.The technological process is composed of one or several sequential processes, and a process consists of a number of working steps.

The technological process

Working procedure is the basic unit of mechanical processing process.So-called working procedure is refers to a (or a group of) workers, on a machine tool (or a working place), to the same workpiece (or several workpiece at the same time) to complete that part of the technological process.The main characteristic of a working procedure is not to change the processing object, equipment and operator, and the content of the working procedure is completed continuously. The working step is under the condition of the same processing surface, the same processing tool and the same cutting amount.

Tool is also known as the work stroke, is the processing tools in the processing of the surface of a complete processing step.

The development of mechanical processing process, it is necessary to determine the workpiece to go through several processes and the sequence of the process, only list the main process name and processing order of the brief process, known as the process route.

The formulation of the process route is to formulate the overall layout of the process, the main task is to choose the processing methods of each surface, determine the processing sequence of each surface, as well as the number of the number of work in the whole process.The formulation of technological route must follow certain principles.

Production types are generally divided into three categories:

1. Single-piece production: products of different structures and sizes are produced individually, with little duplication.

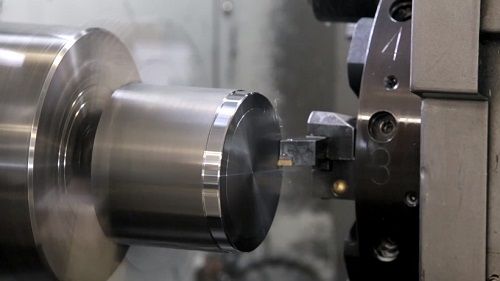

2. Batch production: the same products are manufactured in batches throughout the year, with a certain degree of repeatability in the manufacturing process.

Parts that are mass-produced

Parts that are mass-produced

3. Mass production: the manufacturing quantity of products is very large, and most of the working places often repeat the processing of a certain process of a part.

Post time: Jul-13-2021