In the world of manufacturing, custom machining parts play a crucial role in creating products that meet specific requirements. One material that has gained popularity for its versatility and durability in custom machining is polyoxymethylene (POM), also known as acetal or Delrin. POM is a high-performance engineering plastic that offers excellent dimensional stability, low friction, and high stiffness, making it an ideal choice for a wide range of applications. Custom machining parts with POM material has become a preferred choice for industries such as automotive, aerospace, medical, and consumer goods due to its exceptional mechanical properties and resistance to wear and tear. The ability of POM to withstand high temperatures and harsh environments makes it suitable for demanding applications where precision and reliability are paramount.

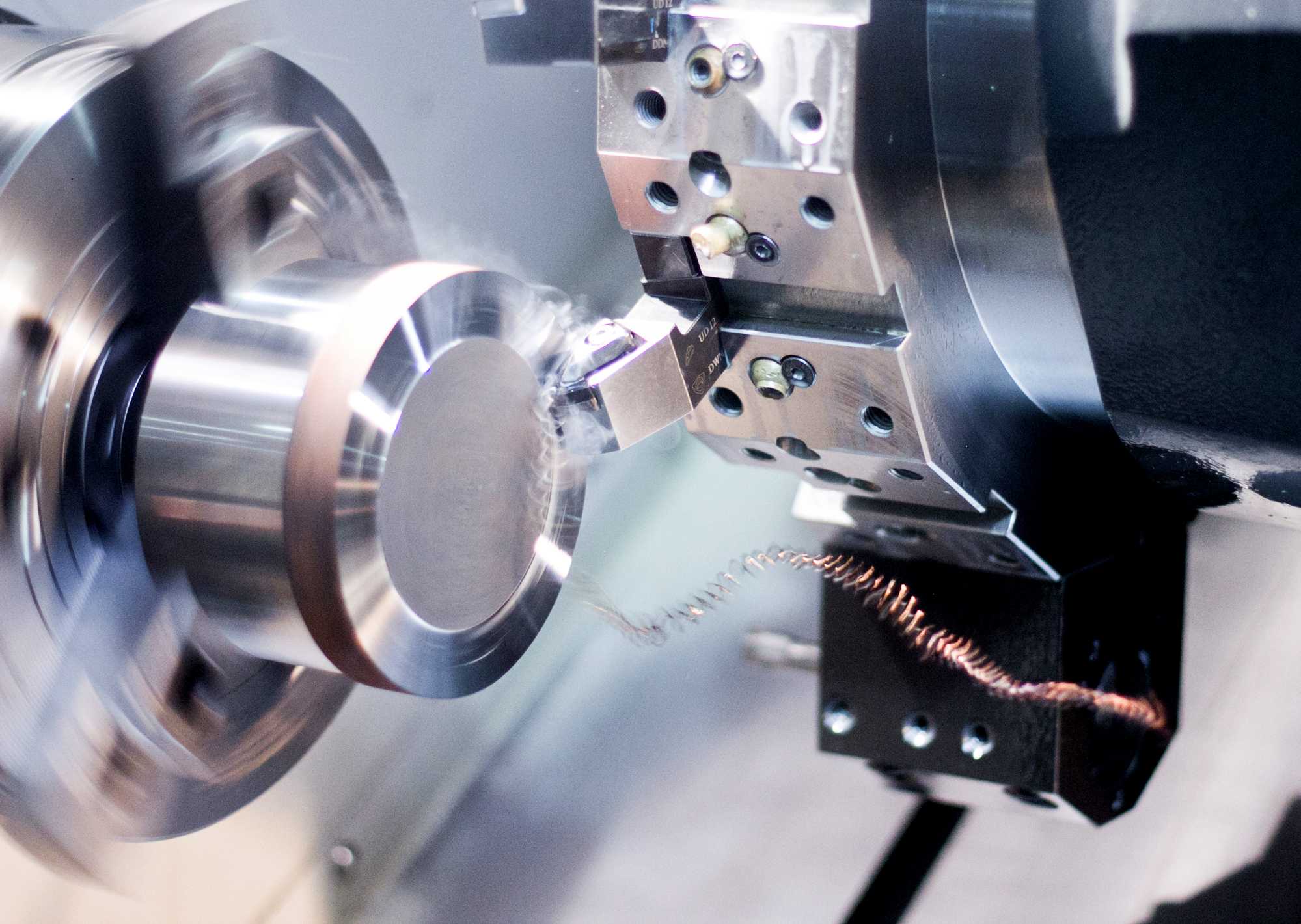

One of the key advantages of using POM material for custom machining parts is its machinability. POM can be easily machined to create complex shapes and intricate designs with tight tolerances, making it a cost-effective solution for producing custom components with high precision. This machinability allows manufacturers to achieve intricate details and fine finishes, meeting the exact specifications of their clients. Furthermore, custom machining parts with POM material offer excellent resistance to chemicals, solvents, and fuels, making them suitable for applications where exposure to harsh substances is a concern. This chemical resistance ensures the longevity and reliability of the machined parts, even in challenging operating environments.

The automotive industry, in particular, has embraced the use of custom machining parts with POM material for various components such as gears, bearings, bushings, and fuel system components. The exceptional wear resistance and low friction properties of POM make it an ideal choice for these critical automotive applications, where durability and performance are essential. In the aerospace sector, custom machining parts with POM material are used in the production of aircraft components, including interior fittings, structural elements, and control system parts. The lightweight nature of POM, combined with its high strength and stiffness, makes it an attractive option for aerospace manufacturers seeking to reduce weight without compromising on performance and reliability.

The medical industry also benefits from custom machining parts with POM material, as it meets the stringent requirements for biocompatibility and sterilization. POM's resistance to moisture and chemicals, along with its ability to withstand repeated sterilization cycles, makes it an ideal choice for medical devices and equipment, ensuring the safety and well-being of patients. Moreover, the consumer goods industry utilizes custom machining parts with POM material for a wide range of products, including electronic devices, appliances, and sporting goods.

The aesthetic appeal, dimensional stability, and smooth surface finish of POM make it a popular choice for creating custom components that enhance the functionality and appearance of consumer products. In conclusion, custom machining parts with POM material offer a myriad of benefits, including exceptional machinability, mechanical properties, chemical resistance, and suitability for diverse industries. As the demand for high-quality, custom-engineered components continues to grow, POM material will undoubtedly remain a top choice for manufacturers seeking to deliver precision, reliability, and performance in their products.

Post time: Aug-19-2024