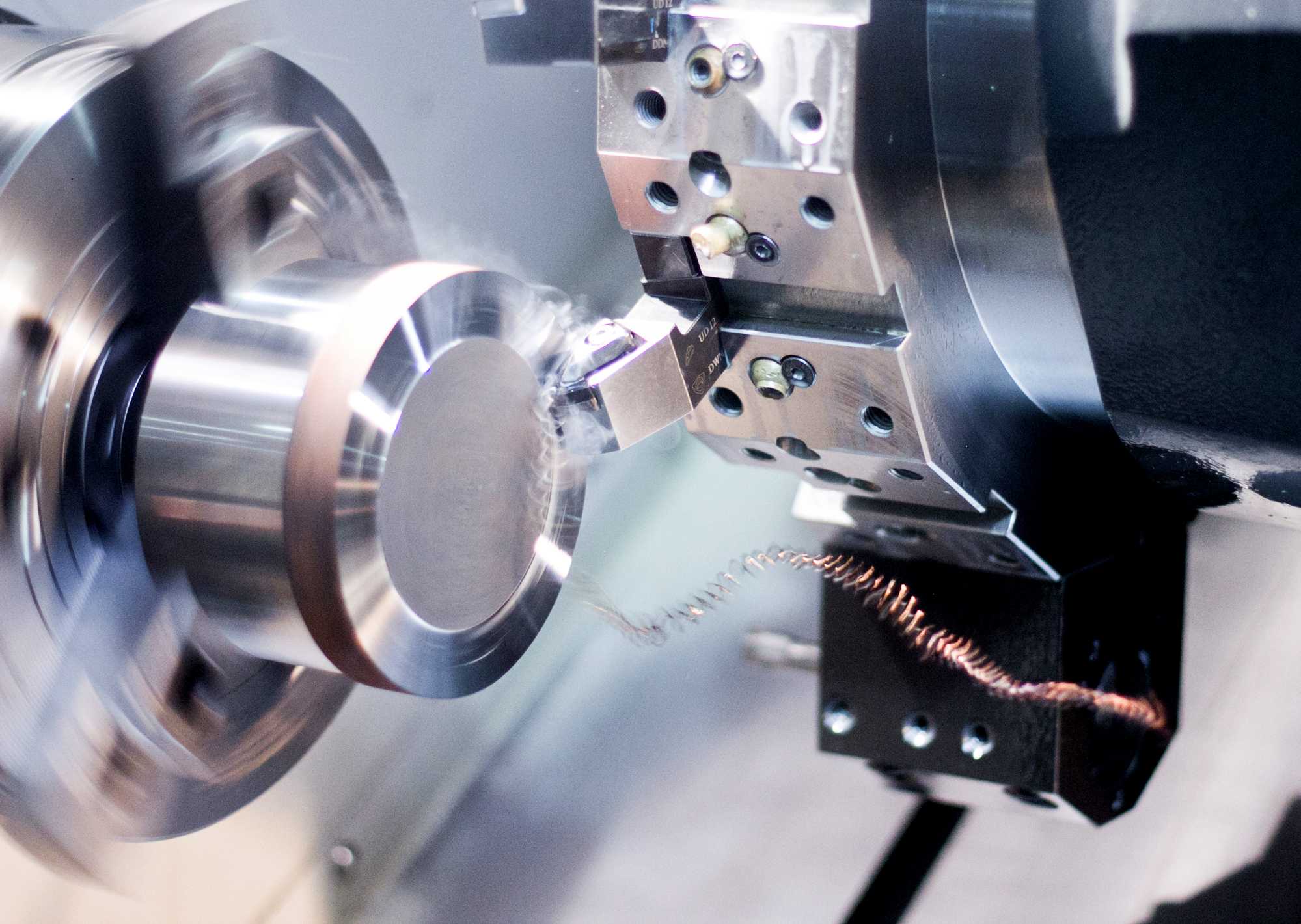

The CNC machining industry in Europe is experiencing significant growth and development, driven by technological advancements and increasing demand for precision engineering solutions. As a result, the region has become a hub for cutting-edge CNC machining technology and innovation, with a strong focus on quality, efficiency, and sustainability. One of the key factors driving the growth of the CNC machining industry in Europe is the increasing adoption of advanced manufacturing technologies. CNC machining, which stands for Computer Numerical Control, involves the use of computer-controlled machines to perform a wide range of manufacturing tasks, including cutting, milling, drilling, and turning.

This technology allows for high levels of precision and repeatability, making it ideal for producing complex and intricate components for various industries, such as aerospace, automotive, medical, and electronics. In addition to technological advancements, the CNC machining industry in Europe is also benefiting from the region's strong emphasis on quality and precision engineering. European manufacturers are known for their meticulous attention to detail and commitment to delivering high-quality products. This reputation has helped the region become a preferred destination for companies seeking reliable and precise CNC machining services. Furthermore, the growing demand for sustainable manufacturing practices is driving the adoption of environmentally friendly CNC machining processes in Europe. Manufacturers are increasingly focusing on reducing waste, energy consumption, and emissions, while also exploring the use of eco-friendly materials and production methods.

This shift towards sustainability is not only driven by regulatory requirements but also by consumer preferences for environmentally responsible products. The CNC machining industry in Europe is also witnessing a trend towards automation and digitalization. Manufacturers are investing in advanced robotics, artificial intelligence, and data analytics to optimize production processes, improve efficiency, and reduce lead times. This digital transformation is enabling European CNC machining companies to stay competitive in a rapidly evolving global market. Moreover, the COVID-19 pandemic has further accelerated the adoption of digital technologies in the CNC machining industry.

The need for remote monitoring, virtual collaboration, and contactless production has prompted manufacturers to fast-track their digitalization efforts. As a result, the industry is becoming more resilient and agile in the face of unforeseen disruptions. Despite the positive growth trajectory, the CNC machining industry in Europe is not without its challenges. One of the key concerns is the shortage of skilled labor, particularly in the field of CNC programming and operation. To address this issue, industry stakeholders are focusing on workforce development initiatives, such as vocational training programs and apprenticeships, to cultivate the next generation of CNC machining talent.

Another challenge facing the European CNC machining industry is the increasing competition from emerging markets. Countries in Asia, particularly China, have been rapidly expanding their CNC machining capabilities and are offering competitive pricing, posing a threat to European manufacturers. To remain competitive, European companies are differentiating themselves through innovation, customization, and superior quality. In conclusion, the CNC machining industry in Europe is experiencing robust growth, driven by technological advancements, a focus on quality and precision, sustainability initiatives, digital transformation, and resilience in the face of challenges. With a strong foundation in engineering expertise and a commitment to innovation, Europe is poised to maintain its position as a global leader in CNC machining. However, continued investment in skills development and strategic differentiation will be crucial for sustaining this momentum in the long term.

Post time: Jul-01-2024