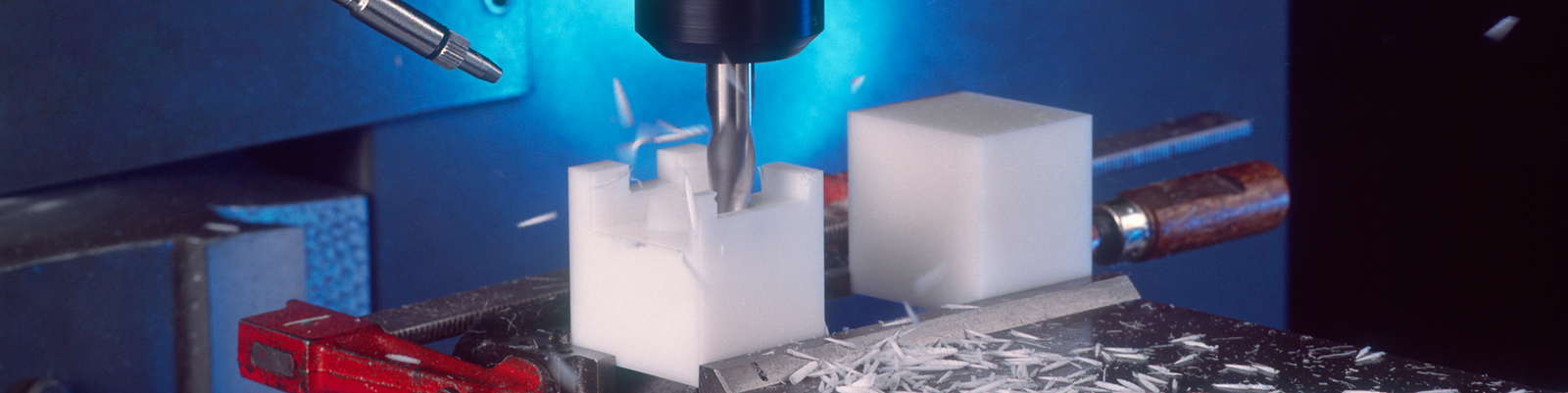

Metal and Plastic Materials in CNC Machining

As we all know, in CNC Machining process, metal and plastic materials are the most common materials. Metal material has the characteristics of good corrosion resistance, good forming properties and easier to process. However, obviously, plastic materials has more good properties, including ABS, Polycarbonate, Nylon, Delrin, HDPE, Polypropylene, Clear Acrylic, PVC, ULTEM™ 1000 Resin, G-10 FR4, etc. and metal materials include Aluminum, Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Brass, Copper, Casting Parts, Forging Parts, etc. To some extent, both materials have their own properties and the buyer should select what they need according to their designation and end-use.

Plastic Materials

|

Material |

Description |

Benefits |

Applications |

|

ABS |

Easy to machine and fabricate | Low cost Good impact resistance Good machinability Easy to paint and glue Good strength and stiffness |

Machined prototypes Structural components Support blocks Housings Covers |

|

Polycarbonate |

Excellent dimensional stability Good strength |

Low moisture absorption Good insulating properties Excellent flammability rating Easy to fabricate and paint |

Structural & Electrical applications Machine guards |

|

Nylon |

Standard grade nylon with natural and black color | Excellent wear resistance Low frictional properties Very good chemical and impact properties |

Metal replacement Bearings Gears |

|

Delrin |

Crystalline plastic, between metals and plastics | Good dimensional stability Excellent machinability High strength Low moisture absorption Good wear and abrasion properties |

Mechanical applications Moist Parts, like pump parts Gears, Bearings, Fittings Electrical insulator parts |

|

HDPE |

Excellent impact resistance High tensile strength Low moisture absorption and chemical corrosion resistance properties |

Light-weight No moisture absorption High tensile strength Non-toxic Non-staining |

|

|

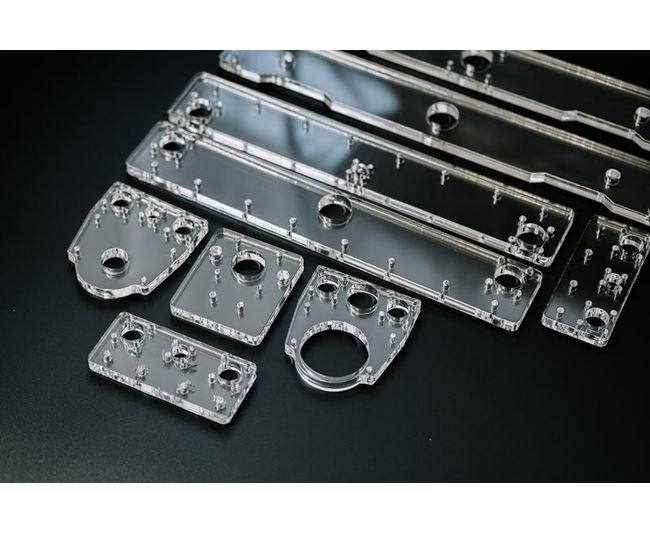

Clear Acrylic |

Rigid, hard thermoplastic | Excellent UV stability | Machine enclosures Model manufacture |

|

PVC |

Normal impact High corrosion resistancy |

Cost efficiency Ease of fabrication Economic balance |

Chemical resistance applications |

Metal Materials

|

Material |

Description |

Benefits |

Applications |

|

Aluminum |

Easy to machine and fabricate compared to the other machining alloys |

Corrosion resistance and appearance after anodizing are superior to other alloys while strength is the lowest |

Aerospace applications All mechanical applications |

|

Carbon Steel Alloy Steel |

Common used in CNC machining Excellent impact resistance High tensile strength Excellent chemical corrosion resistance properties |

Good corrosion resistance in mild environments Good forming properties |

Aircraft applications Machine parts Pump and valve parts Architectural applications Nuts and bolts, etc. |

|

Casting and Forging Parts |

Common used in CNC machining Excellent impact resistance |

Good corrosion resistance in mild environments Good forming properties Custom properties |

Machinery Parts |

|

Bronze, Brass, and Copper Alloy |

Commonly known material, great for electrical conductivity. |

Good corrosion Easily machined |

Great for gears, valves, fittings and screws. |

Post time: Jan-10-2021