Stainless steel AISI304 machining parts have become an integral component of modern manufacturing processes, playing a crucial role in the production of a wide range of products across various industries. From automotive and aerospace to medical and consumer goods, the demand for precision-engineered stainless steel AISI304 parts continues to grow, driven by the material's exceptional properties and versatility. One of the key factors contributing to the popularity of stainless steel AISI304 machining parts is their superior corrosion resistance. This makes them ideal for applications in harsh environments where exposure to moisture, chemicals, and other corrosive elements is a concern. Additionally, AISI304 stainless steel parts offer excellent strength and durability, making them well-suited for demanding operational conditions.

The versatility of stainless steel AISI304 machining parts is another compelling aspect that has led to their widespread adoption. These parts can be machined into complex shapes and sizes with high precision, allowing for the production of custom components tailored to specific requirements. This flexibility makes AISI304 stainless steel parts suitable for a diverse array of applications, ranging from intricate medical devices to heavy-duty industrial machinery. In the automotive industry, stainless steel AISI304 machining parts are utilized in the production of engine components, exhaust systems, and structural elements. The material's resistance to corrosion and high-temperature performance make it an ideal choice for these critical applications, contributing to the overall reliability and longevity of automotive vehicles.

Similarly, in the aerospace sector, the demand for stainless steel AISI304 machining parts is driven by the material's ability to withstand extreme conditions, including temperature variations and exposure to atmospheric elements. From aircraft components to satellite structures, AISI304 stainless steel parts play a vital role in ensuring the safety and performance of aerospace systems. The medical industry also relies heavily on stainless steel AISI304 machining parts for the fabrication of surgical instruments, implants, and medical devices. The biocompatibility and corrosion resistance of AISI304 stainless steel make it a preferred material for these applications, where precision and reliability are paramount.

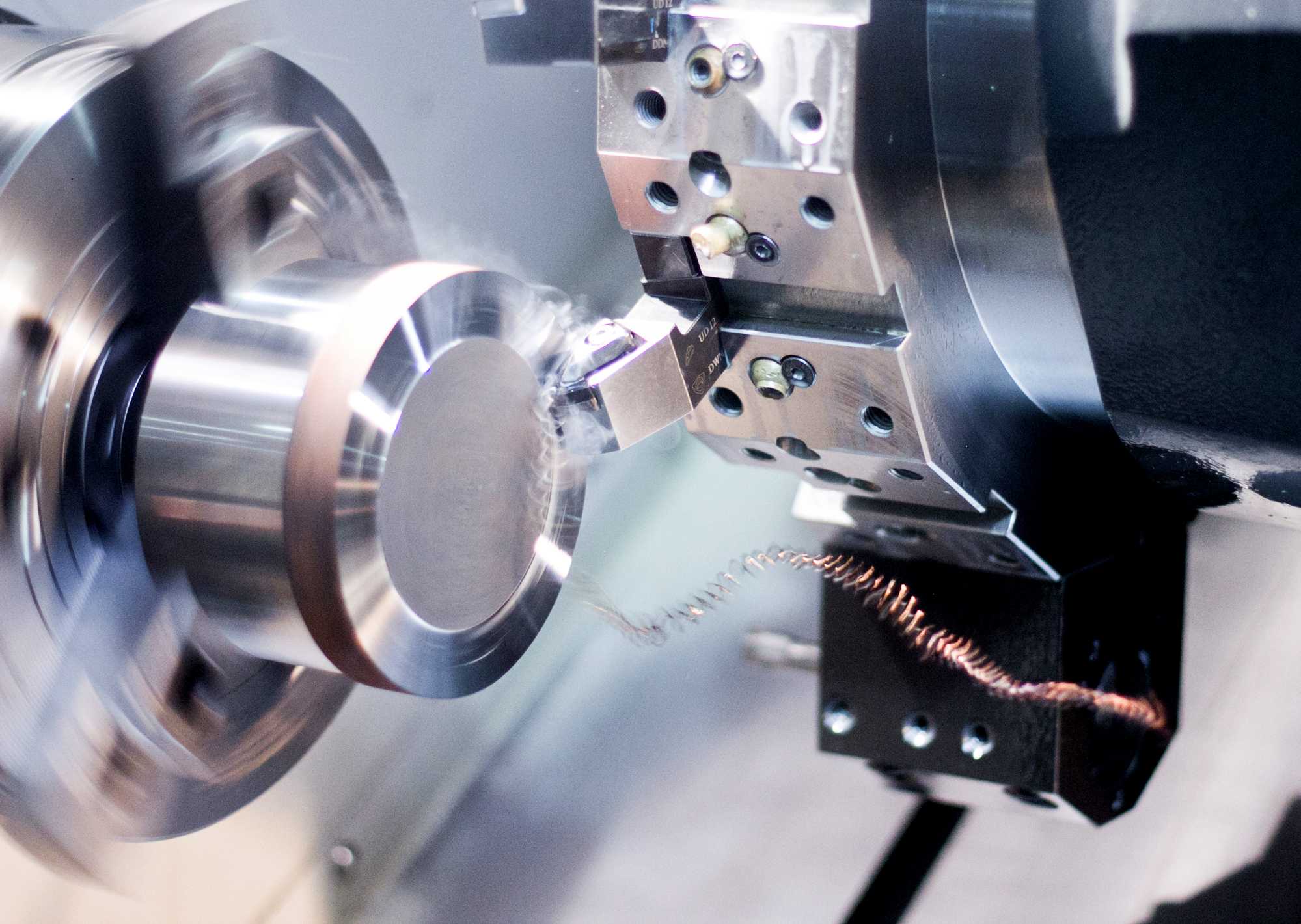

Furthermore, the consumer goods sector benefits from the use of stainless steel AISI304 machining parts in the production of household appliances, kitchenware, and decorative items. The aesthetic appeal, hygiene, and durability of AISI304 stainless steel contribute to the quality and longevity of consumer products, meeting the expectations of discerning consumers. As the demand for stainless steel AISI304 machining parts continues to rise, manufacturers are leveraging advanced machining technologies and processes to meet the evolving needs of various industries. Computer numerical control (CNC) machining, precision grinding, and laser cutting are some of the techniques employed to fabricate intricate and high-quality AISI304 stainless steel parts with tight tolerances.

In conclusion, stainless steel AISI304 machining parts have emerged as the backbone of modern manufacturing, offering a combination of exceptional properties, versatility, and reliability. With their widespread applications across diverse industries, AISI304 stainless steel parts are poised to remain indispensable in driving innovation and progress in the global manufacturing landscape.

Post time: Aug-05-2024