In recent years, the industrial sector has experienced a significant transformation with the introduction of advanced materials and technologies. Among these, tantalum flanges and pipes have emerged as game-changers, revolutionizing various industries. Tantalum, known for its exceptional properties and applications, is rapidly replacing traditional materials due to its superior performance and durability. Let's delve deeper into the extraordinary capabilities of tantalum flanges and pipes and their impact on a wide range of sectors.

Tantalum Flanges:

Tantalum flanges are highly sought after in the oil and gas, chemical, and petrochemical industries. These flanges offer exceptional corrosion resistance, making them ideal for applications involving harsh chemicals and extreme temperatures. With tantalum flanges, industries can ensure the safe and efficient operation of their equipment and pipelines, minimizing the risk of leaks and costly downtime. Additionally, tantalum's high melting point and excellent thermal conductivity make it a preferred choice for heat exchangers, further enhancing the overall operational efficiency of various processes.

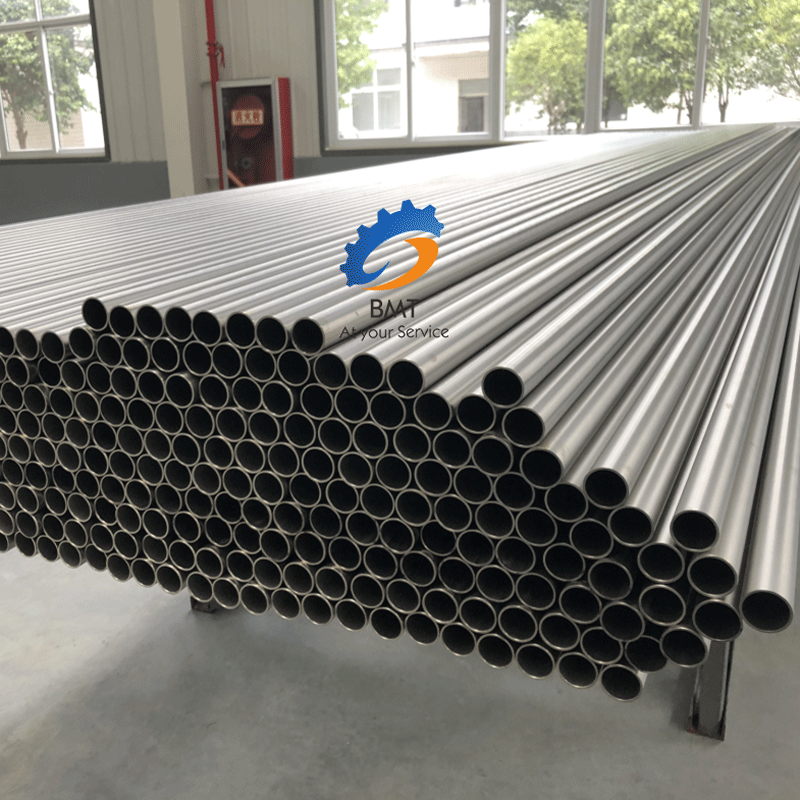

Tantalum Pipes:

Tantalum pipes, known for their exceptional purity and resistance to corrosion, have become a key component in numerous industries. These pipes are extensively used in the semiconductor and electronics sectors, where they play a critical role in the production of integrated circuits and other electronic components. Tantalum pipes provide a reliable and contamination-free environment required for these delicate processes, ensuring the highest quality and performance of electronic devices. Moreover, the chemical processing industry benefits immensely from tantalum pipes due to their ability to withstand highly corrosive environments and extreme temperatures.

Sustainable and Environmentally Friendly Solution:

Tantalum is not only known for its outstanding mechanical properties but also for its sustainable nature. Its extraction process ensures minimal environmental impact, making it a preferred choice for industries striving for eco-friendly solutions. Furthermore, tantalum's extended service life significantly reduces the need for frequent replacements, lowering the overall carbon footprint associated with manufacturing and maintenance activities.

Future Prospects and Challenges:

The growing demand for tantalum flanges and pipes highlights the significant opportunities that lie ahead. The aerospace and defense sectors are also exploring tantalum's potential in propulsion systems and military applications, further fueling the demand for these advanced materials. However, the limited availability of tantalum remains a challenge, as it is a rare metal mainly sourced from conflict-prone regions. To tackle this issue, industry players are actively promoting responsible mining practices and exploring alternative materials with similar properties.

Conclusion:

Tantalum flanges and pipes have ushered in a new era for various industries, offering unparalleled performance and resilience. Their exceptional properties, ranging from corrosion resistance to high thermal conductivity, make them indispensable in sectors such as oil and gas, chemical processing, electronics, and more. Furthermore, tantalum's sustainability and minimal ecological impact position it as a frontrunner in the development of eco-friendly solutions. As demand grows, it is crucial for manufacturers to focus on responsible sourcing and seek alternatives to ensure the continued availability of tantalum for years to come.

Post time: Jul-31-2023