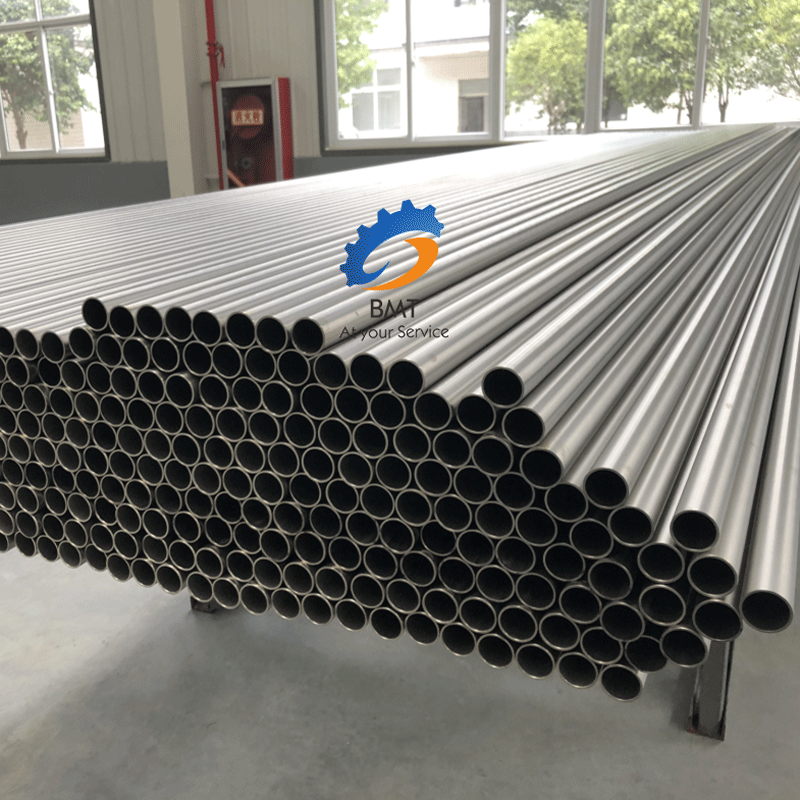

The industrial manufacturing sector is always striving to find innovative solutions that improve product quality, increase efficiency, and reduce costs. In recent news, the introduction of titanium assembly fittings has created a ripple of excitement across various industries. This breakthrough technology promises to revolutionize assembly processes, offering unparalleled strength, durability, and numerous advantages over traditional materials. Let's delve into the details of this game-changing development.

Unmatched Strength and Lightweight Construction:

Titanium, known for its exceptional strength-to-weight ratio, has long been revered in various applications. With a tensile strength comparable to steel but only about half its weight, titanium assembly fittings offer an unmatched combination of strength and lightweight construction. This characteristic substantially improves the overall performance of assemblies without compromising their structural integrity, resulting in enhanced product efficiency and longevity.

Resistance to Corrosion and Extreme Temperatures:

One of the most outstanding qualities of titanium is its exceptional resistance to corrosion. Compared to other metals, titanium is highly resilient to the detrimental effects of moisture, saltwater, certain chemicals, and even extreme temperatures. This corrosion resistance makes titanium assembly fittings an ideal choice for industries such as aerospace, marine, oil and gas, and chemical manufacturing, where harsh environmental conditions are prevalent.

Improved Efficiency and Cost Savings:

The titanium assembly fittings' lightweight construction not only improves product performance but also leads to significant efficiency gains. The reduced weight facilitates easier handling, installation, and transportation, streamlining assembly processes and reducing labor costs. Additionally, titanium's exceptional resistance to corrosion eliminates the need for frequent replacements or repairs, thereby minimizing downtime and reducing maintenance expenses.

Enhanced Safety and Reliability:

The superior strength and durability of titanium assembly fittings translate into enhanced safety and reliability standards. With the ability to withstand substantial mechanical stress and fatigue, titanium fittings offer a higher margin of safety, which is crucial in safety-critical industries such as aviation and automotive manufacturing. The reliability of titanium also ensures assemblies can withstand long-term exposure to harsh operational conditions, resulting in fewer failures and improved overall product performance.

Environmental Sustainability:

In addition to its mechanical properties, titanium assembly fittings contribute to environmental sustainability. Titanium is a fully recyclable material with a low carbon footprint. Its long lifespan and resistance to corrosion reduce waste and the need for frequent replacements, thus minimizing the environmental impact associated with manufacturing processes. The adoption of titanium fittings aligns with the increasing emphasis on sustainable practices, making it an attractive choice for environmentally-conscious industries.

Potential Challenges and Future Outlook:

While the advantages of titanium assembly fittings are undeniably compelling, some challenges remain. The high cost of titanium compared to traditional materials may pose an initial barrier to widespread adoption. However, as technology advances and economies of scale come into play, the cost disparity is expected to reduce gradually.

Looking forward, the future of titanium assembly fittings appears promising. Ongoing research and development efforts are focused on enhancing manufacturing techniques, reducing costs, and expanding the range of applications. As these innovations progress, titanium assembly fittings are likely to become more accessible, revolutionizing numerous industries and opening doors to novel opportunities for improved product design and performance.

In conclusion, the introduction of titanium assembly fittings marks a significant milestone in industrial manufacturing. With their unparalleled strength, lightweight construction, resistance to corrosion, and exceptional durability, titanium fittings offer a game-changing solution for various industries. While challenges remain, the potential benefits of this breakthrough technology are immense, promising improved efficiency, cost savings, enhanced safety, and environmental sustainability. With further advancements on the horizon, titanium assembly fittings are set to redefine the standards of assembly processes, propelling the industrial manufacturing sector into a new era of excellence.

Post time: Aug-21-2023