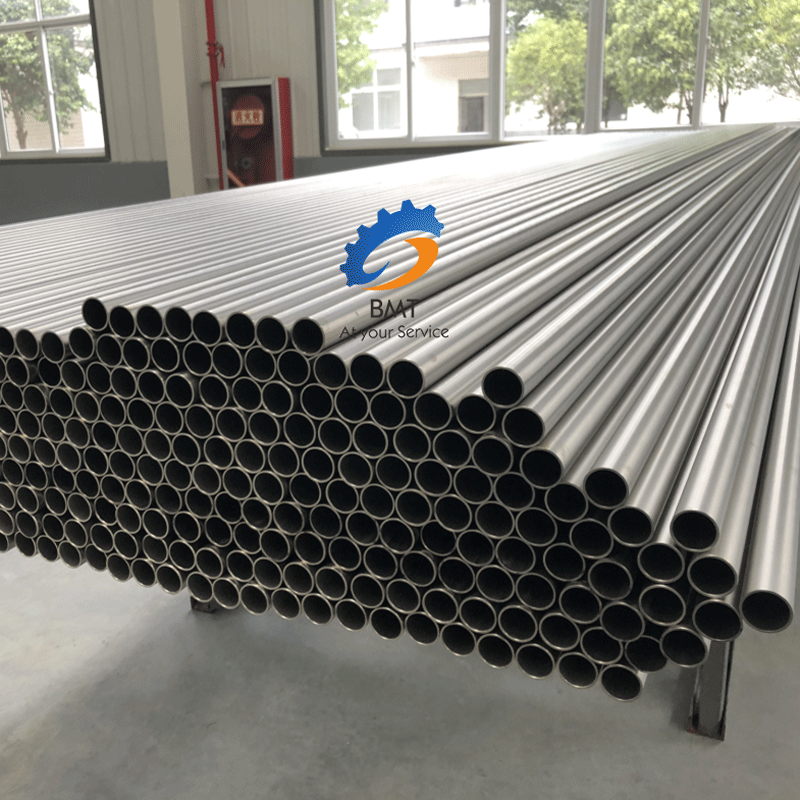

In a significant development in the metallurgical industry, titanium fittings with ASTM/ASME standard have made their mark, providing revolutionary solutions across various sectors. The introduction of these fittings brings a new level of durability, strength, and corrosion resistance, offering immense benefits for industries such as aerospace, chemical processing, oil and gas, and more. Titanium, known for its unmatched strength-to-weight ratio, has long been a sought-after material in industries that demand high performance under challenging conditions. With the addition of ASTM/ASME standard fittings, titanium's potential has reached new heights.

These fittings adhere to the stringent quality and performance criteria established by the American Society for Testing and Materials (ASTM) and the American Society of Mechanical Engineers (ASME), ensuring exceptional reliability and compatibility. One of the major advantages of titanium fittings with ASTM/ASME standard lies in their ability to withstand extreme temperatures and pressures. This makes them ideal for applications in the oil and gas industry, where they can be exposed to harsh environments, high pressures, and corrosive fluids. The implementation of these fittings significantly reduces maintenance costs and enhances the overall safety of operations.

Moreover, the aerospace industry has also embraced titanium fittings as a game-changer. With its lightweight properties and high strength, titanium is a perfect fit for aircraft structures. By employing ASTM/ASME standard fittings, the industry can now achieve superior quality, precision, and performance in aircraft components, ensuring safer and more efficient flights. The chemical processing industry, which deals with highly corrosive fluids, benefits immensely from the corrosion resistance of titanium fittings. Traditional materials often succumb to chemical attacks, leading to frequent replacements and downtime. However, the implementation of ASTM/ASME standard titanium fittings provides a durable solution, minimizing maintenance efforts and increasing productivity.

Another notable application for titanium fittings is in the medical field. Titanium's non-toxic nature and biocompatibility make it an ideal choice for medical implants, such as artificial joints, dental implants, and cardiovascular devices. With the added assurance of ASTM/ASME standards, the medical community can trust in the reliability and safety of titanium fittings, greatly enhancing patient outcomes. Furthermore, the introduction of titanium fittings with ASTM/ASME standard opens up new possibilities for various construction projects. From bridges and stadiums to architectural marvels, titanium fittings offer greater design flexibility and longevity compared to conventional materials. Their resistance to corrosion, weathering, and wear ensures that structures remain sturdy and aesthetically pleasing for years to come.

However, it is important to note that despite the remarkable benefits of titanium fittings with ASTM/ASME standard, their cost remains relatively higher than traditional fittings. The specialized manufacturing processes and stringent quality control measures contribute to the increased cost. Nevertheless, the long-term advantages and durability that titanium fittings bring to industries outweigh the initial investment.

In conclusion, the advent of titanium fittings with ASTM/ASME standard marks a significant milestone in the metallurgical industry. These fittings offer exceptional strength, corrosion resistance, and durability, making them invaluable across various sectors. From aerospace to medical, oil and gas to construction, the wide-ranging applications and benefits of titanium fittings ensure a brighter and more advanced future for industries worldwide.

Post time: Jul-10-2023