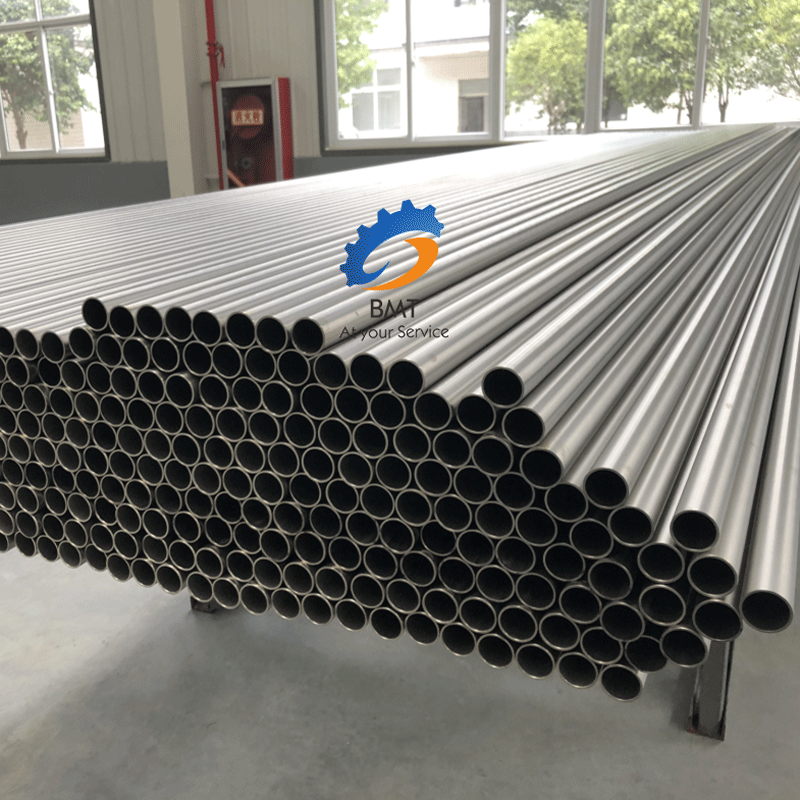

In a significant breakthrough for the manufacturing industry, engineers and researchers have successfully developed a pioneering Titanium Gr2 Machined Part. This new advancement in machining technology is expected to revolutionize various industries and bring about substantial improvements in product performance and overall quality. Titanium Gr2, also known as Grade 2 titanium, is widely recognized for its exceptional strength, lightweight nature, and superior corrosion resistance. These desirable qualities make it an ideal choice for multiple applications, including aerospace, automotive, medical, and even sporting goods.

However, the machining of this material has always posed challenges due to its high strength and tendency to overheat. Addressing these challenges head-on, the team of engineers and researchers leveraged their expertise to develop an innovative machining technique that ensures superior precision, efficiency, and reduced lead times. The Titanium Gr2 Machined Part not only retains the inherent properties of the titanium alloy but also offers enhanced dimensional accuracy with minimal material waste. One of the key advantages of this new machining technique is its ability to significantly reduce the machining time, thereby boosting productivity.

Manufacturers can now accomplish complex machining operations at an accelerated pace without compromising on the structural integrity of the final product. This breakthrough is expected to greatly benefit the aerospace and automotive industries, where the demand for high-quality, lightweight components is ever-growing. Furthermore, the Titanium Gr2 Machined Part has demonstrated exceptional resistance to corrosion even in harsh and corrosive environments. This durability feature extends the lifespan of the machined parts and reduces the need for frequent replacements, saving both time and resources. In the medical field, the integration of this innovative titanium machining technique will have far-reaching implications.

The Titanium Gr2 Machined Part possesses biocompatible properties, making it suitable for various medical applications such as implants, prosthetics, and surgical instruments. Its lightweight nature and compatibility with the human body offer immense potential for improving patient comfort, reducing complications, and enhancing overall medical outcomes. Additionally, the sports equipment industry is set to benefit significantly from this breakthrough. With the Titanium Gr2 Machined Part, sports manufacturers can now create superior performance-enhancing gear, including bicycles, tennis rackets, and golf clubs. These products will be characterized by their exceptional strength, lightness, and enhanced durability, giving athletes a competitive edge.

The development of the Titanium Gr2 Machined Part marks a significant milestone in the manufacturing industry. Its impact will extend beyond specific sectors, influencing a wide range of applications and encouraging further innovations in machining technologies. This breakthrough will undoubtedly foster economic growth, job creation, and enhanced capabilities across various industries. As the manufacturing industry continues to evolve, the demand for high-performance materials and cutting-edge machining techniques becomes increasingly pronounced. With the Titanium Gr2 Machined Part, manufacturers will be well-equipped to meet these demands and push the boundaries of what is possible. This groundbreaking innovation reaffirms the remarkable capabilities of human ingenuity and sets the stage for a new era of manufacturing excellence.

Post time: Jul-26-2023