The aerospace industry is constantly pushing the boundaries of what is possible, and one of the key factors in achieving breakthroughs in this field is the use of high precision machining techniques. One material that is particularly challenging to work with is titanium, due to its extremely high strength and low thermal conductivity. However, recent advancements in high precision machining have made it possible to machine titanium to incredibly tight tolerances, leading to significant advancements in the aerospace industry. Titanium is prized for its strength-to-weight ratio, making it an ideal material for aerospace applications.

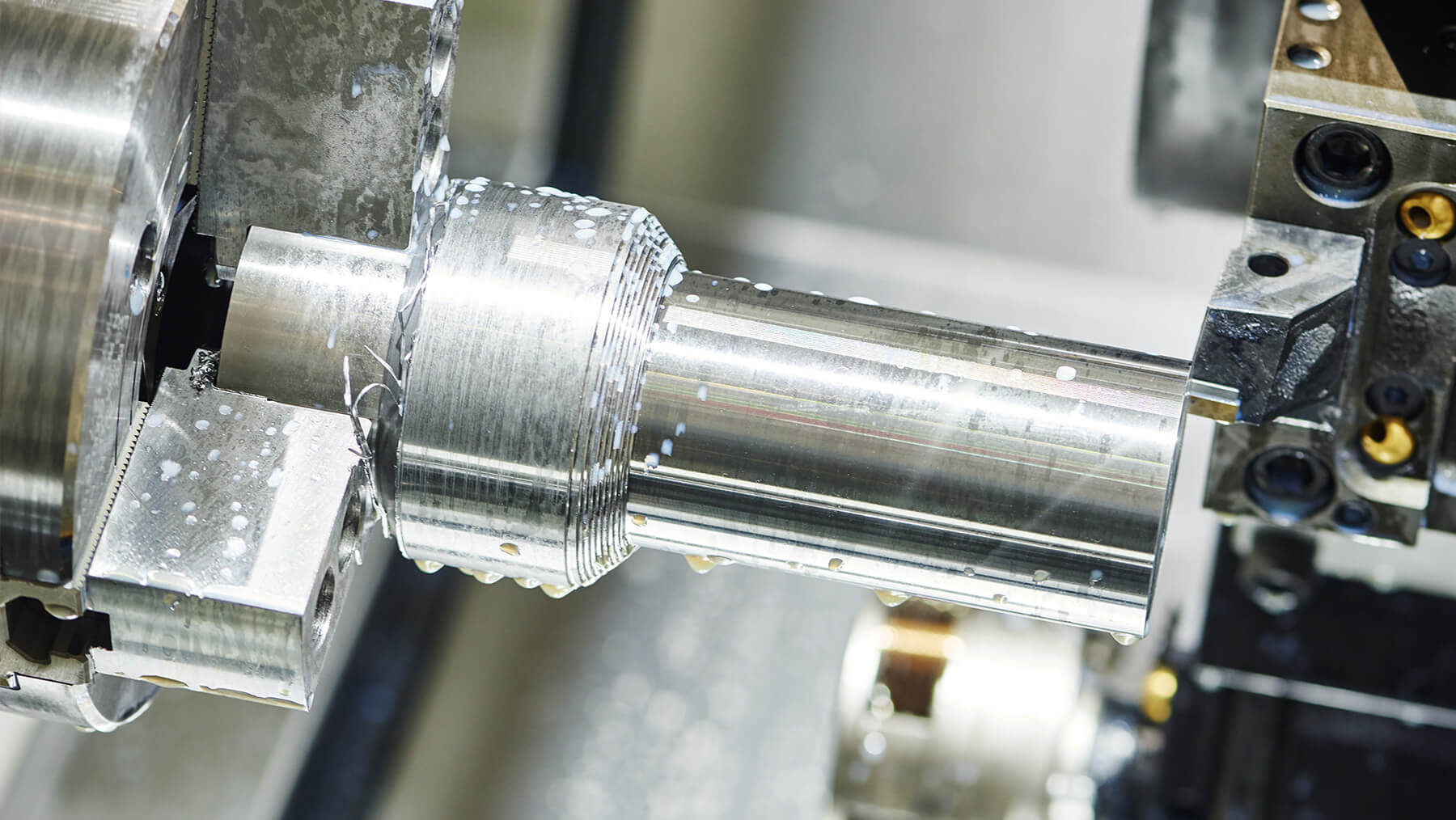

However, its toughness also makes it notoriously difficult to machine. Traditional machining techniques often result in a significant amount of tool wear and a slow cutting speed, which can lead to inconsistencies and inaccuracies in the finished parts. This has hindered the widespread use of titanium in aerospace components, as the manufacturing process has been a limiting factor in its application. However, recent developments in high precision machining have made it possible to overcome these challenges. Advanced cutting tools, including high-performance carbide and ceramic inserts, as well as improved cutting strategies and toolpath optimization, have allowed for much more efficient and precise machining of titanium.

This has opened up new possibilities for the design and manufacture of aerospace components, leading to breakthroughs in performance and efficiency. For example, high precision machining of titanium has made it possible to produce lighter and stronger components for aircraft and spacecraft, leading to improvements in fuel efficiency and overall performance. Additionally, the ability to machine titanium to extremely tight tolerances has allowed for the development of more complex and intricate parts, leading to advancements in aerodynamics and overall design flexibility. These advancements have the potential to revolutionize the aerospace industry, leading to more efficient and capable aircraft and spacecraft.

Furthermore, high precision machining of titanium has also led to advancements in the design and manufacture of aircraft engines and propulsion systems. The ability to machine titanium to incredibly tight tolerances has allowed for the development of more efficient and powerful engines, leading to improvements in thrust-to-weight ratios and overall performance. This has the potential to revolutionize air travel and space exploration, opening up new possibilities for faster and more efficient propulsion systems. The advancements in high precision machining of titanium have not only had a significant impact on the aerospace industry, but also on other high-tech industries such as medical and automotive.

The ability to machine titanium to extremely tight tolerances has led to breakthroughs in the design and manufacture of medical implants and devices, as well as high-performance automotive components. This has the potential to improve the quality of life for millions of people and revolutionize the automotive industry. Overall, the advancements in high precision machining of titanium have the potential to revolutionize multiple industries, leading to breakthroughs in performance, efficiency, and overall capabilities. As technology continues to evolve, the possibilities for machining titanium to even tighter tolerances will continue to expand, leading to further advancements in aerospace, medical, automotive, and other high-tech industries.

Post time: Mar-05-2024