Titanium Precision Machining Manufacturer Implements Cutting-Edge Technology to Enhance Production

In a bid to excel in the highly competitive precision machining industry, one renowned manufacturer of titanium components has recently incorporated state-of-the-art technology into its production process. The company, known for its unparalleled expertise in titanium machining, aims to further enhance its precision capabilities and deliver top-notch products to its customers around the world. With years of experience under its belt, the company has constantly strived to stay at the forefront of technological advancements. This latest investment showcases its commitment to continually improving operations and meeting the evolving needs of its clients.

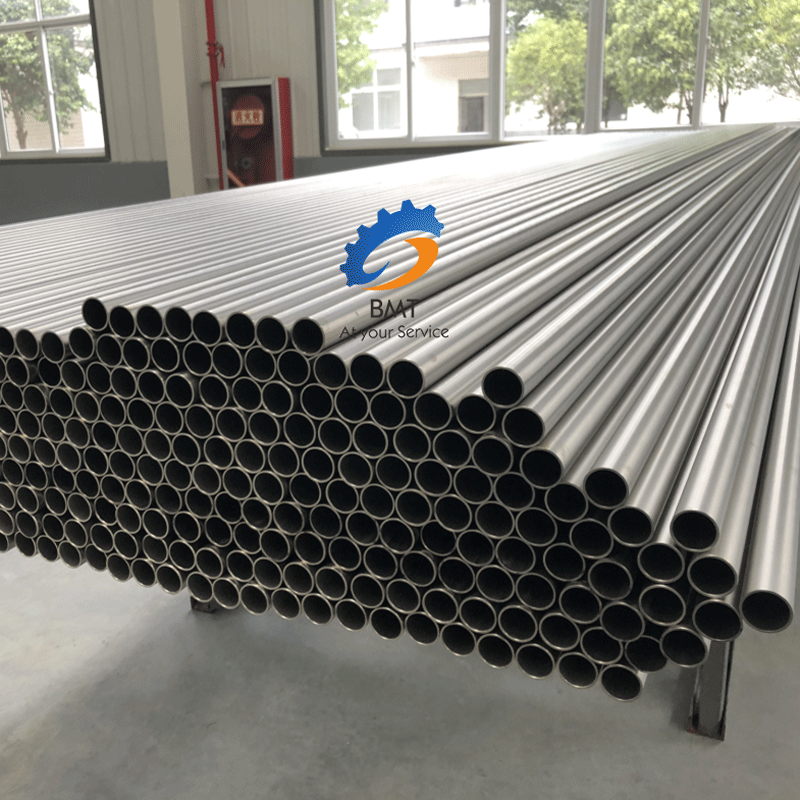

By integrating cutting-edge machinery and software, the manufacturer has unlocked new opportunities for innovation and efficiency. The introduction of advanced machinery has significantly elevated the precision and accuracy of the manufacturing process. The company now boasts state-of-the-art computer numerical control (CNC) machines, which employ precise cutting tools to shape titanium components according to exact specifications. This technology ensures consistent quality and adherence to tight tolerances, crucial in industries such as aerospace, medical, and automotive.

Furthermore, the implementation of sophisticated software systems has revolutionized the design and manufacturing processes. Powerful computer-aided design (CAD) and computer-aided manufacturing (CAM) software allow for advanced part modeling, efficient toolpath generation, and optimized machining strategies. These digital solutions have not only increased productivity but have also reduced errors and shortened lead times, positioning the company as a reliable and efficient partner. The enhanced production capabilities have not gone unnoticed, as several high-profile clients have already shown interest in the manufacturer's offerings.

The aerospace sector, in particular, presents a significant growth opportunity for the company, where precision and reliability are of utmost importance. With its newfound ability to produce intricate titanium components with uncompromising precision, the manufacturer is poised to establish itself as a key player in this industry. Moreover, the company recognizes the importance of sustainability and responsible manufacturing practices. With titanium being renowned for its lightweight and high-strength properties, it is an optimal choice for reducing carbon emissions in various industries. By maximizing the potential of this durable and eco-friendly material, the manufacturer contributes to a greener future.

In addition to its cutting-edge technology, the company attributes its success to a highly skilled workforce. With a team of experienced engineers and technicians, each possessing a deep understanding of titanium machining, the company is capable of overcoming even the most intricate challenges. Employee training programs and continuous professional development initiatives ensure that the workforce remains up-to-date with the latest industry trends.

As the precision machining industry evolves, this titanium manufacturer stands ready to adapt and grow alongside it. By investing in advanced technology, the company upholds its commitment to delivering superb products and maintaining its position as a leader in the market. As clients demand ever-higher levels of precision, this manufacturer is well-equipped to surpass their expectations and provide them with cutting-edge solutions.

Post time: Jul-03-2023