OEM manufacturer China Cnc Machining Parts - What are the Ways to Ensure and Improve Machining Accuracy? – Basile Detail:

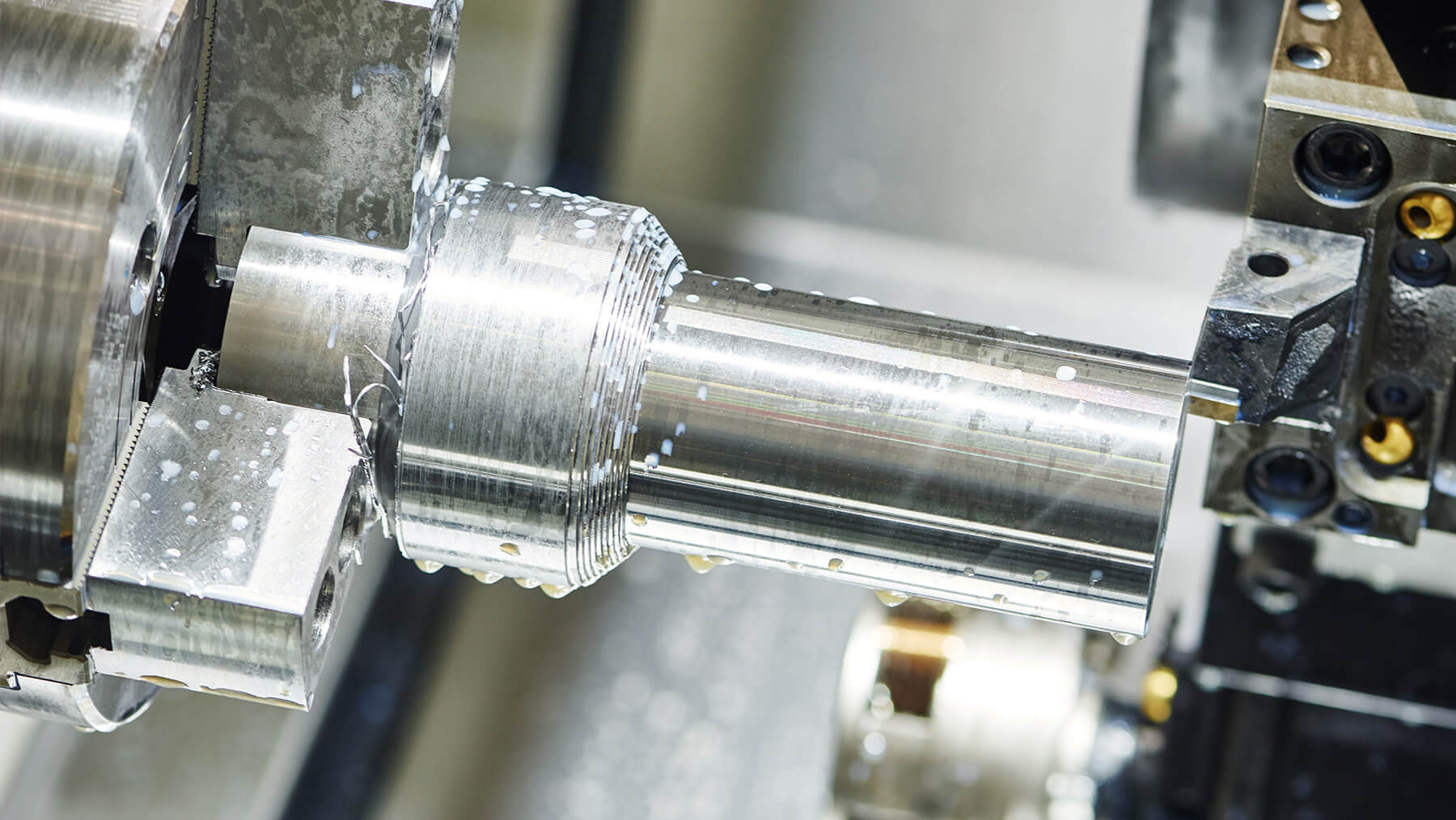

What are the Ways to Ensure and Improve Machining Accuracy?

1) Error prevention technology: reasonable use of advanced technology and equipment to directly reduce the original error transfer original error inferior original error homogenization original error.

2) Error compensation technology: online detection of automatic matching mill active control of the decisive role of error factors.

-What does machining surface geometry include?

Geometric roughness, surface corrugancy, texture direction, surface defects.

-What are the physical and chemical properties of the surface layer material?

1) Cold work hardening of surface layer metal

2) Metallographic deformation of surface layer metal

3) Residual stress of surface layer metal

-Try to analyze the factors affecting the machining surface roughness?

1) The roughness value consists of: the height of the residual cutting area.

2) Main factors: tip arc radius, main deflection Angle, deflection Angle feed

3) Secondary factors: increasing the cutting speed, selecting the cutting fluid appropriately and increasing the rake Angle of the tool to improve the grinding quality of the tool

-Analyze the factors affecting the surface roughness of grinding process.

1) Geometric factors: the influence of grinding amount on surface roughness

2) Influence of grinding wheel granularity and grinding wheel dressing on surface roughness

3) Influence of physical factors: plastic deformation of surface layer metal: selection of grinding dosage wheel

Try to analyze the factors affecting the cold work hardening of the cutting surface?

The influence of cutting parameters the influence of tool geometry the influence of material properties

What is grinding temper burn? What is grinding quench burn? What is grinding annealing burn?

1) Tempering: If the temperature in the grinding zone does not exceed the transformation temperature of the hardened steel, but has exceeded the martensite transition temperature, the workpiece surface metal martensite will be converted to a lower hardness of the tempered structure

2) Quenching: if the temperature in the grinding zone exceeds the phase transition temperature, combined with the cooling effect of the coolant, the surface metal will appear secondary quenching martensite structure, the hardness is higher than the original martensite; In its lower layer, due to slower cooling, tempered tissue with lower hardness than the original tempered martensite appears

Annealing: If the temperature in the grinding zone exceeds the phase change temperature and there is no coolant during the grinding process, the surface metal will have an annealed structure and the hardness of the surface metal will decrease sharply.

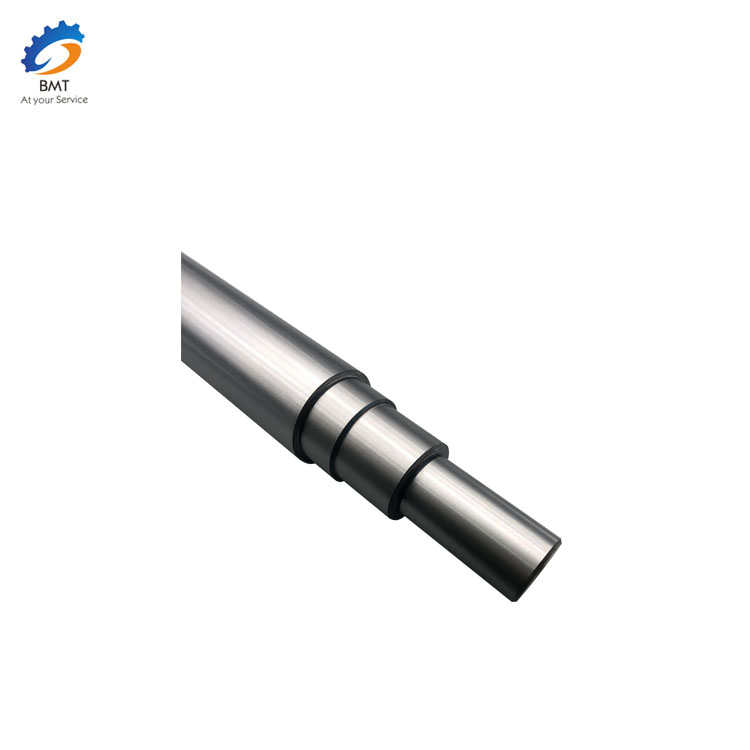

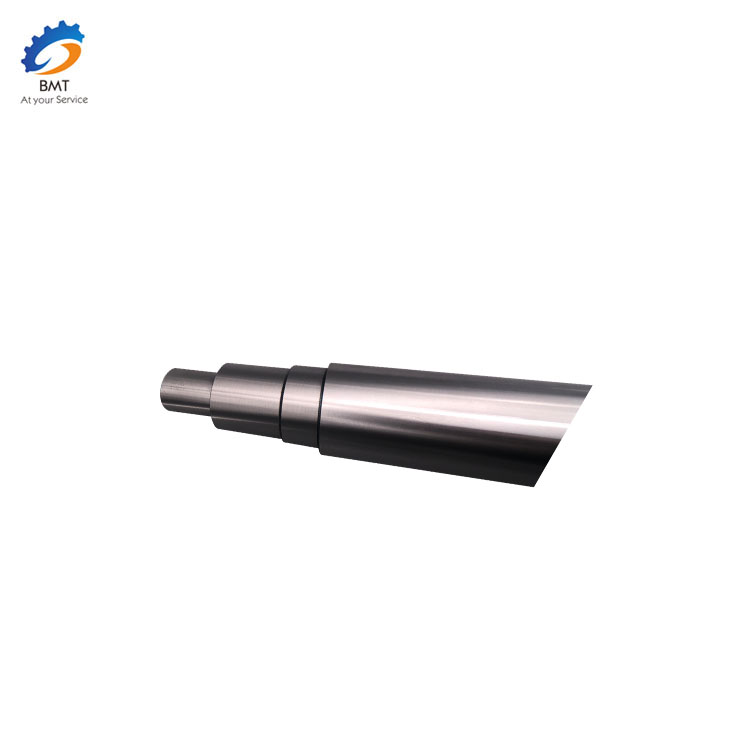

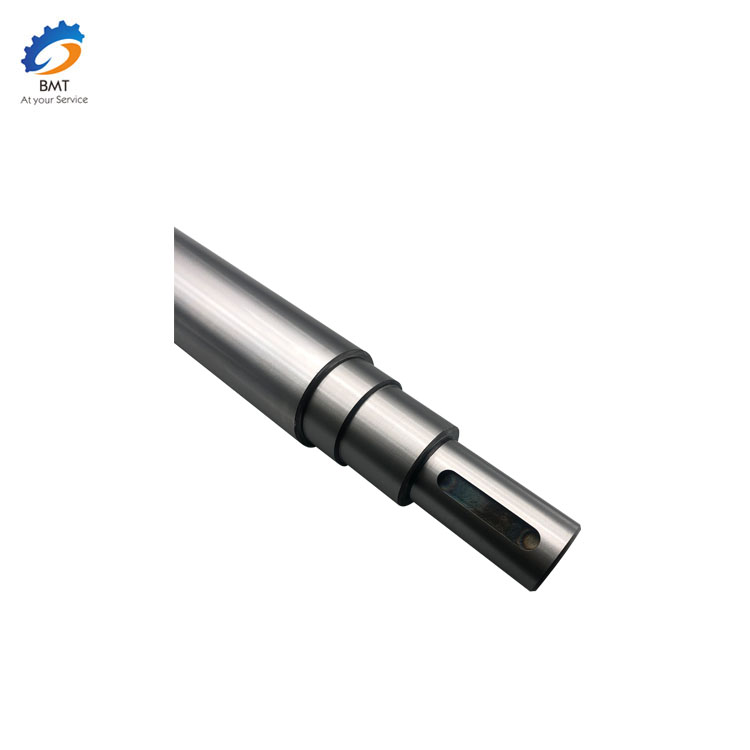

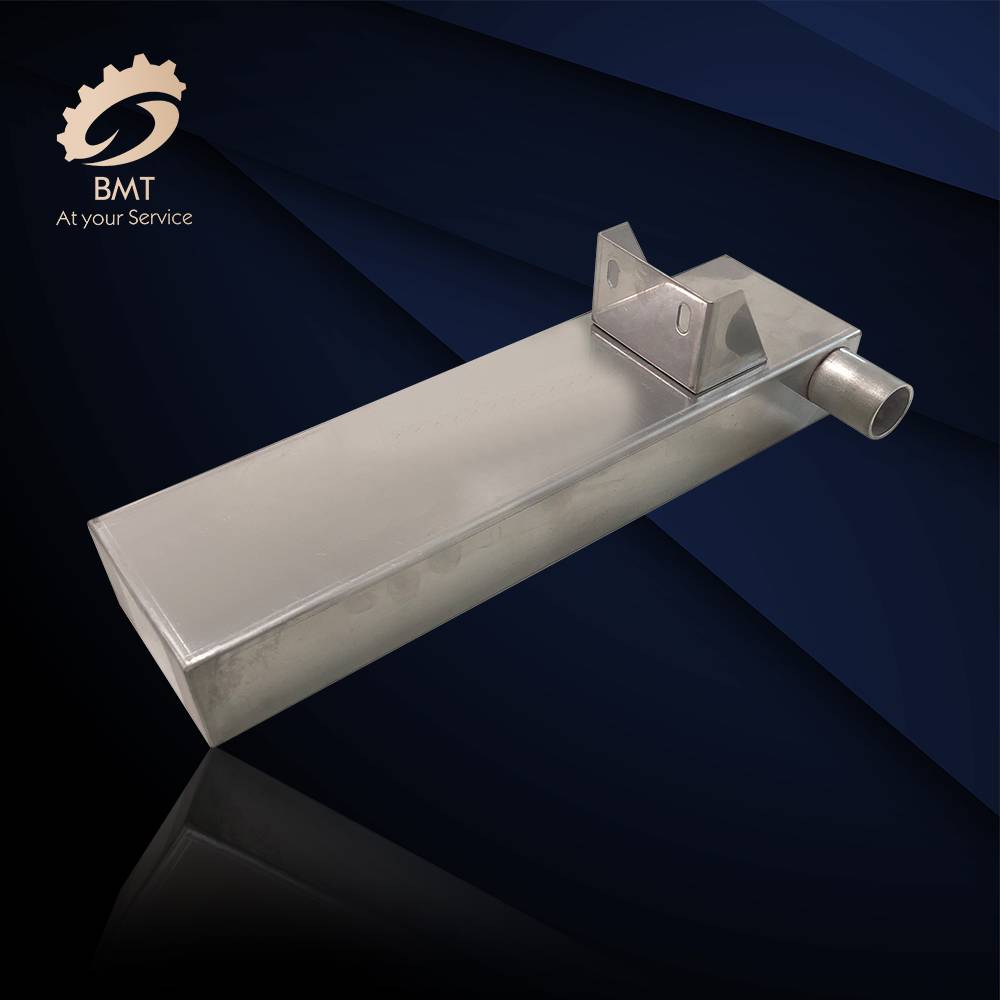

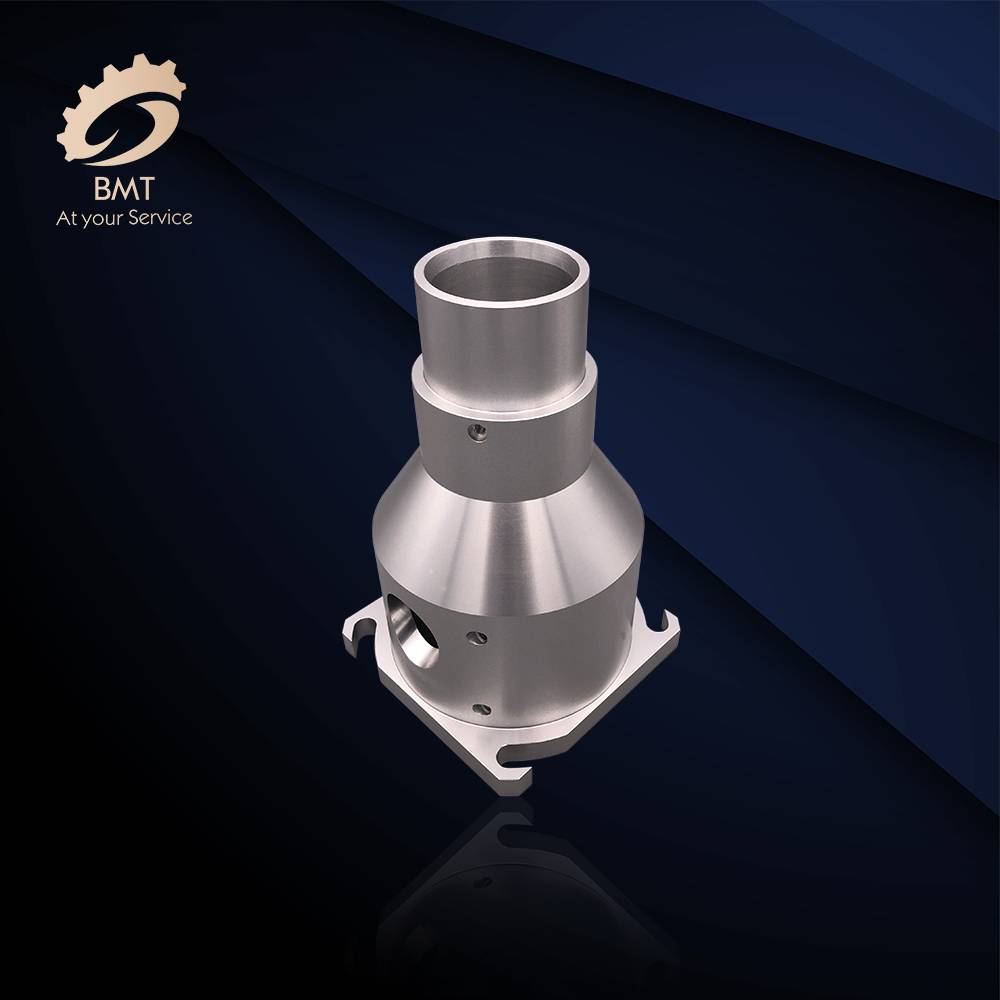

Product detail pictures:

Related Product Guide:

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for OEM manufacturer China Cnc Machining Parts - What are the Ways to Ensure and Improve Machining Accuracy? – Basile, The product will supply to all over the world, such as: Comoros, Jamaica, Southampton, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Send your message to us:

-

Manufacturer of Stainless Steel Precision Cnc ...

-

2021 High quality Sheet Metal Shops Around Me -...

-

Factory directly Cnc Turned Parts Manufacturer ...

-

Chinese wholesale Oem Stamping Parts - Aluminu...

-

2021 Good Quality Ames Sheet Metal - Precision...

-

OEM Manufacturer Engine Parts Machining - CNC ...