professional factory for Custom Sheet Metal Enclosures - OEM Sheet Metal Fabrication – Basile Detail:

Categories of Sheet Metal Fabrication

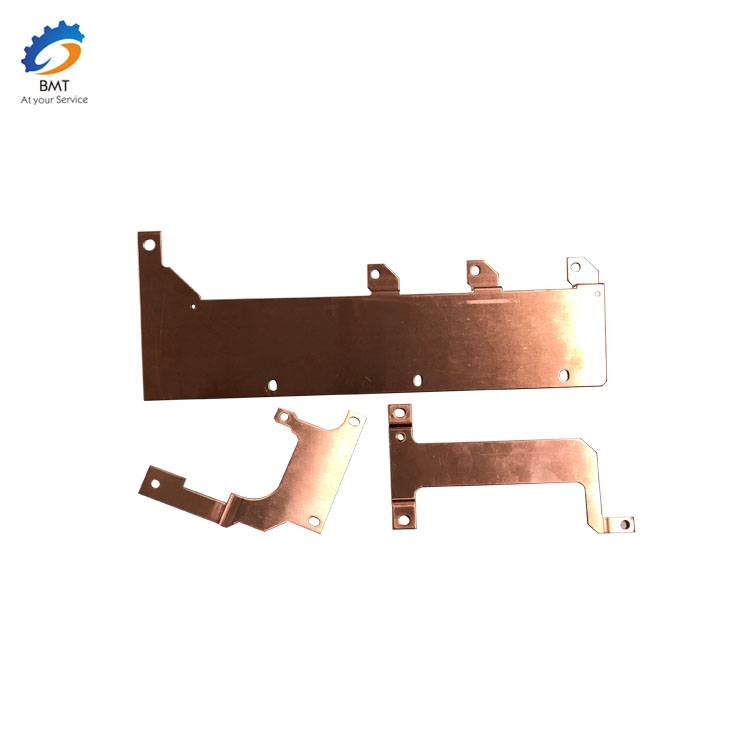

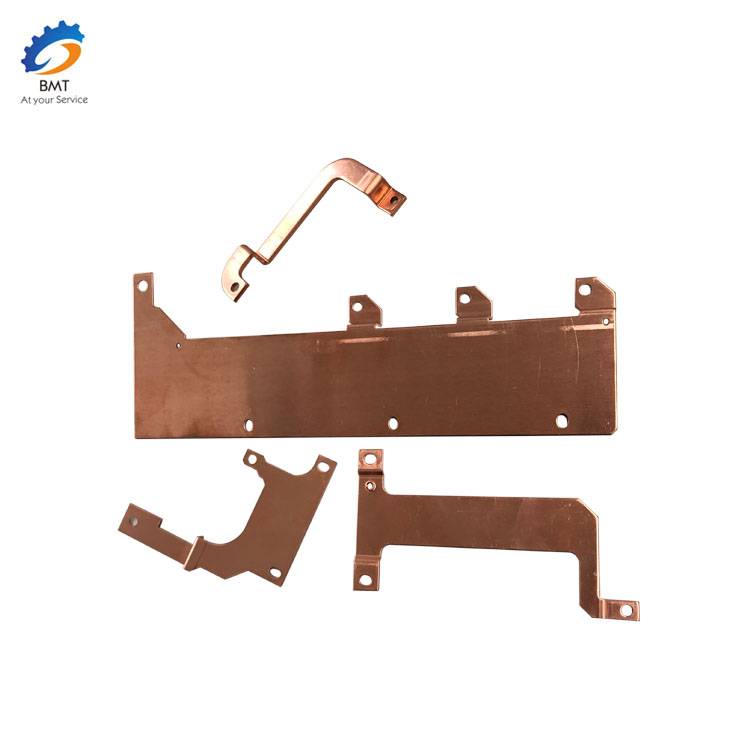

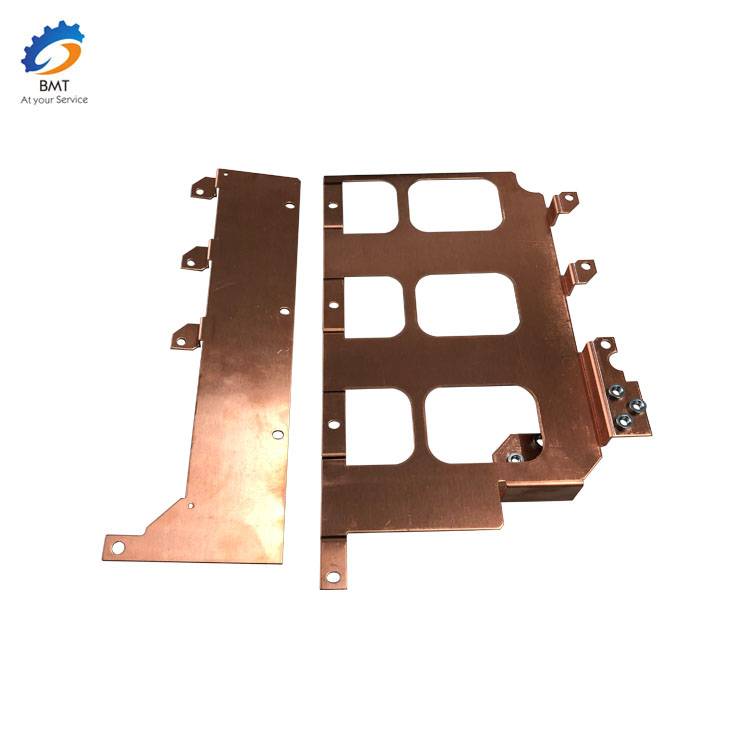

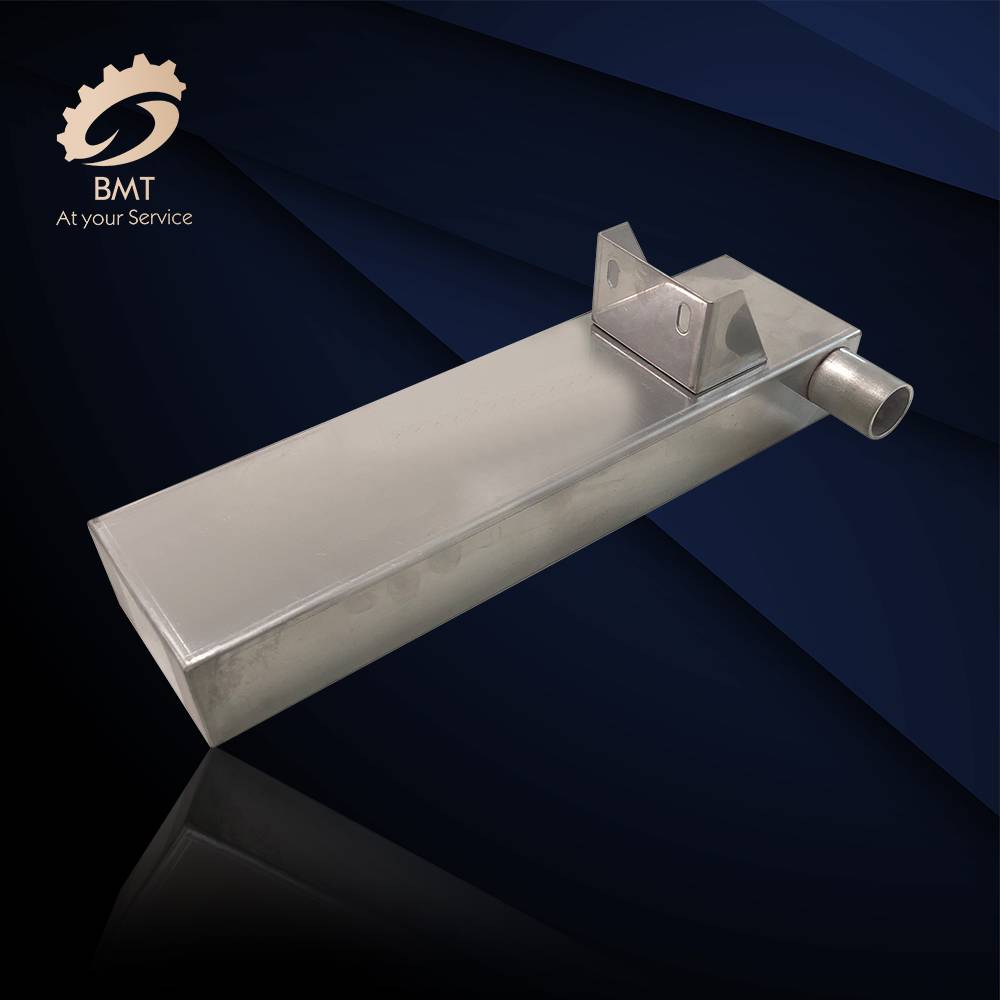

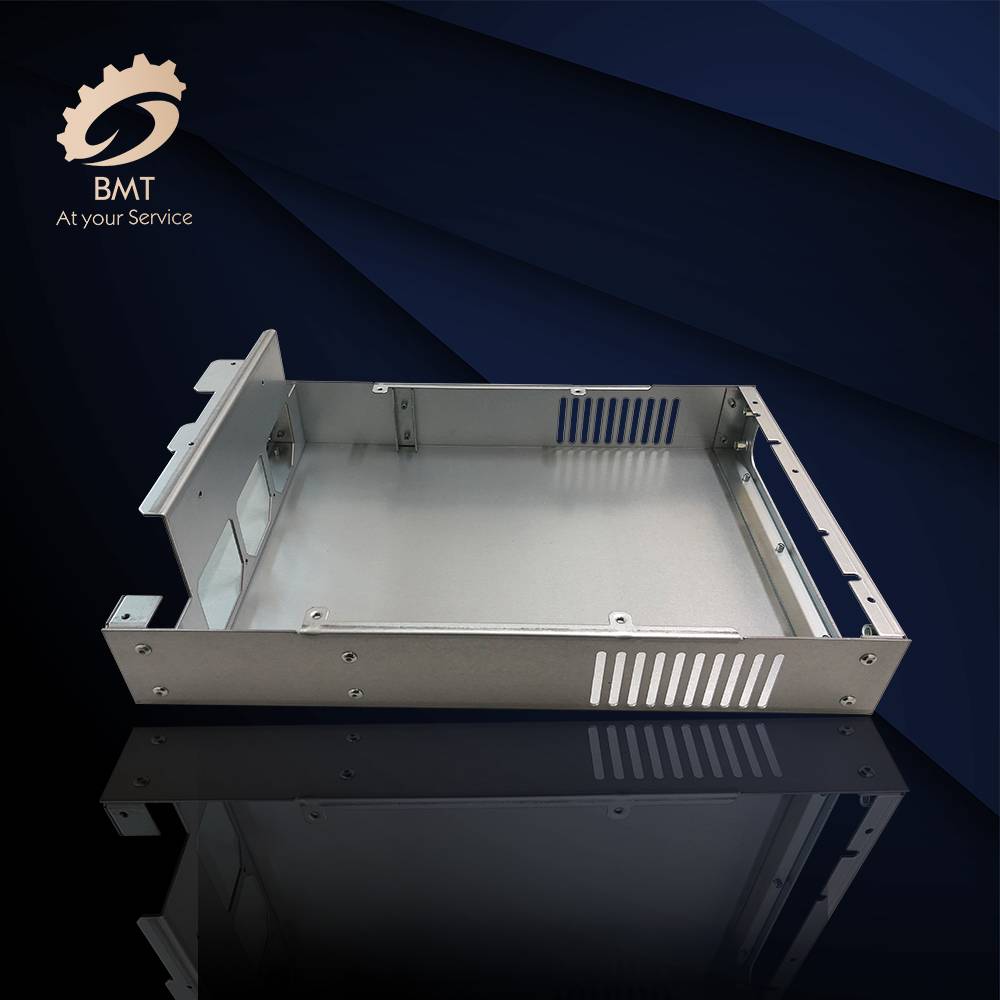

Custom Sheet Metal Fabrication in BMT refers to the manufacturing progress of forming a single or mass production metal sheet parts with custom shapes. Under this progress, it includes many manufacturing ways such as cutting, stamping, punching, bending, press forming, welding, rolling, braking, assembling, galvanizing, powder coating, painting, riveting, etc.

Custom Sheet Metal Fabrication in BMT refers to the manufacturing progress of forming a single or mass production metal sheet parts with custom shapes. Under this progress, it includes many manufacturing ways such as cutting, stamping, punching, bending, press forming, welding, rolling, braking, assembling, galvanizing, powder coating, painting, riveting, etc.

What Are The Advantages Of Custom Metal Fabrication?

In the first place, custom sheet metal fabrication parts are highly durable. With good properties of high structural strength and longevity, it is good for both prototyping and end-use.

In the second place, the custom parts can be built from a full range of Sheet metal materials, and offer a broad range of mechanical properties.

In the third place, production is cost-efficient. With the high efficiency of replicating ability, the metal fabrication machines can produce parts at a low cost per unit. Meanwhile, due to the high efficiency of manufacturing way, parts can be built and delivered at a rapid turnaround.

Last but not least, it can be customized into different sizes with all kinds of finishes.

Three industries’ categories involves in most sheet metal fabrication: Commercial, Industrial and Structural.

Commercial Fabrication refers to sheet metal fabrication done while creating commercial products. This category covers goods designed for use by consumers. Appliances, electronics, and cars, etc. are all common consumer products produced through commercial fabrication.

Industrial Fabrication refers to sheet metal fabrication done while creating other mechanical equipment. Manufacturers are the main consumers of most products produced through industrial sheet metal fabrication. For example, tools like bandsaws, hydraulics, and drill presses are produced through industrial fabrication.

Structural Fabrication refers to metalworking done while building process. It is the process of bending, cutting, and assembling structural steel to create parts, machines, or structures. Structural steel fabricators use machinery to construct a steel piece viable for structural assembly. Large-scale sheet metal fabrication projects create the metal components used by shops, manufacturers, buildings, and skyscrapers. Under normal conditions, metal siding, structural framing studs, roofing, and load bearing fall into this category.

With so many industries reliant on sheet metal fabrication, it is easy to see why there is such a large consumer base for fabricated sheet metal products. If you need more help finding a sheet metal fabricator for your custom project, we are here to help.

We are waiting to assist you with whatever your manufacturing needs may be. Contact us today for your needs.

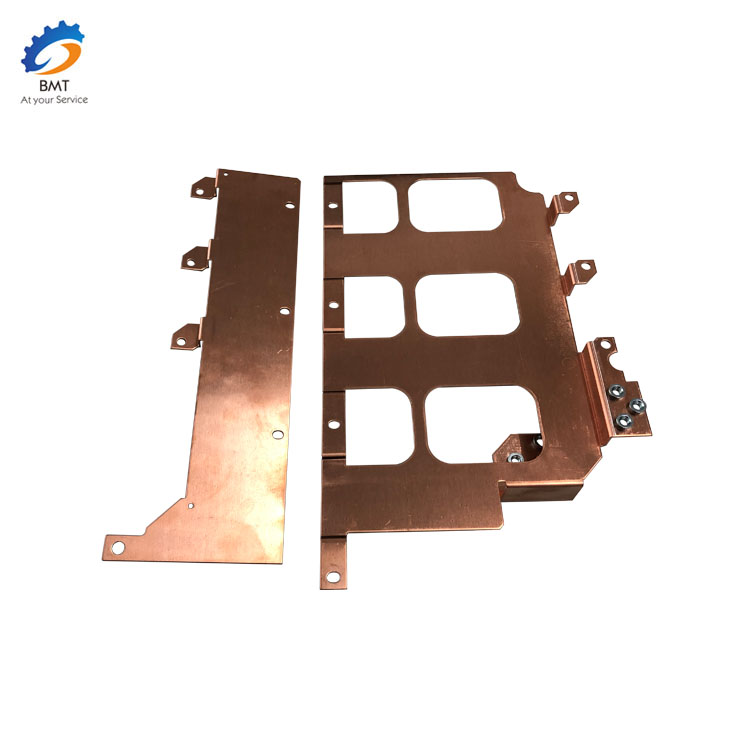

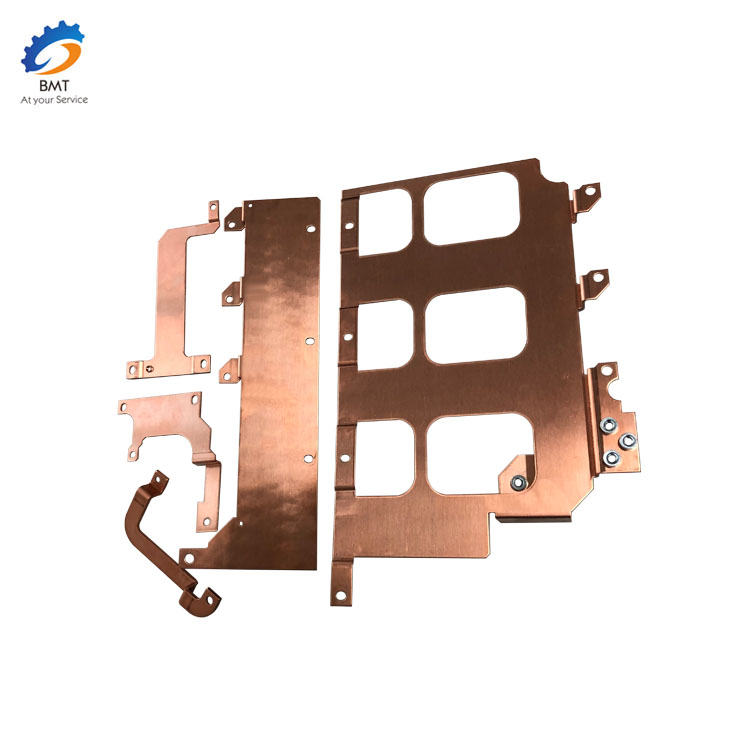

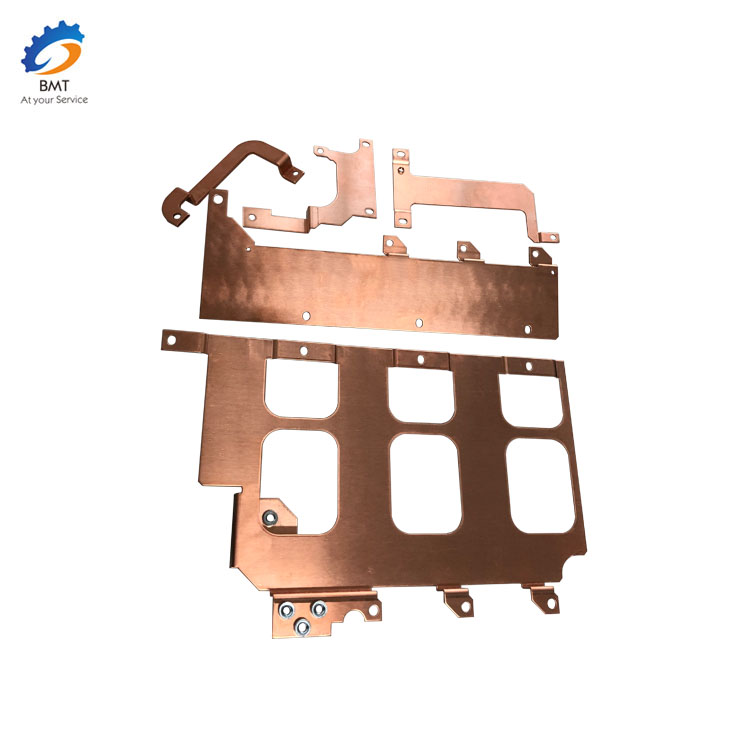

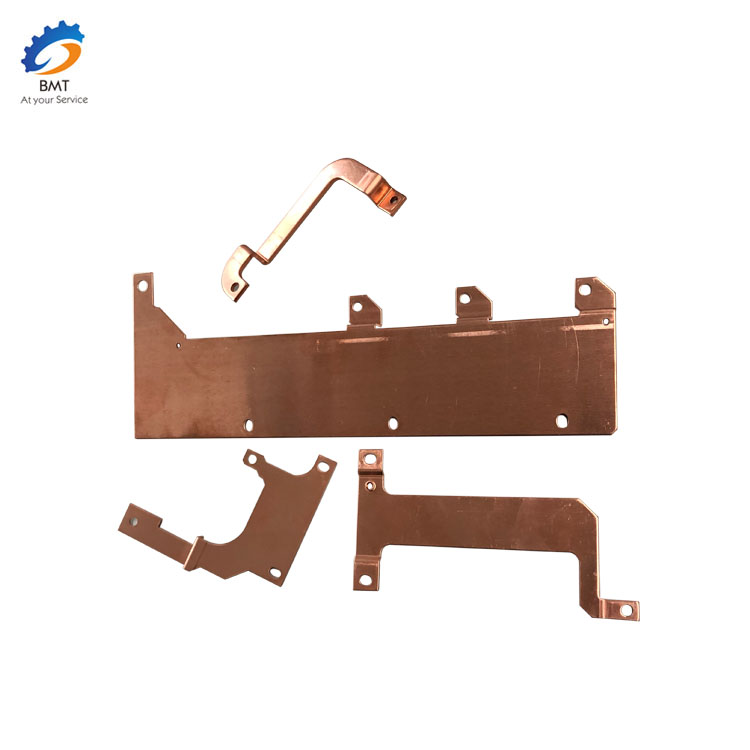

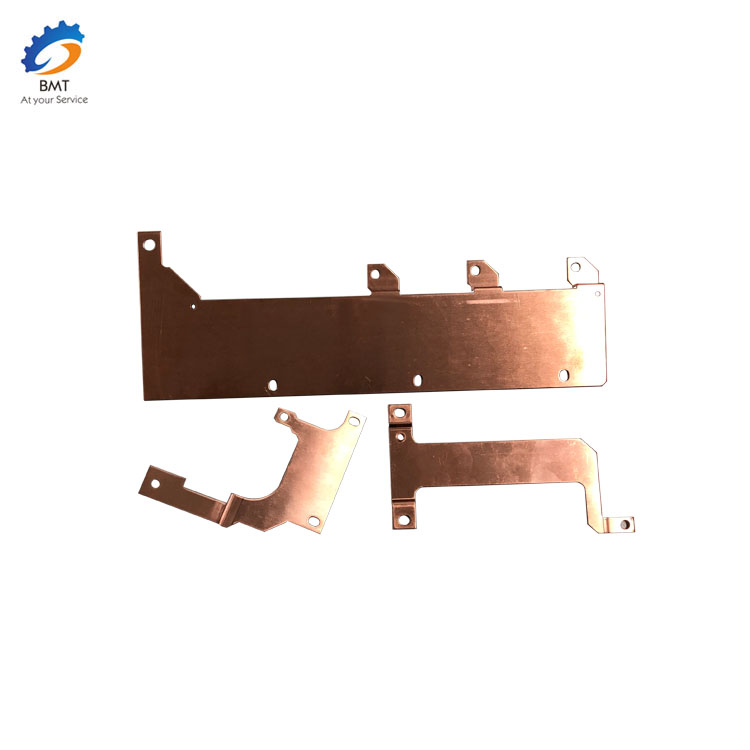

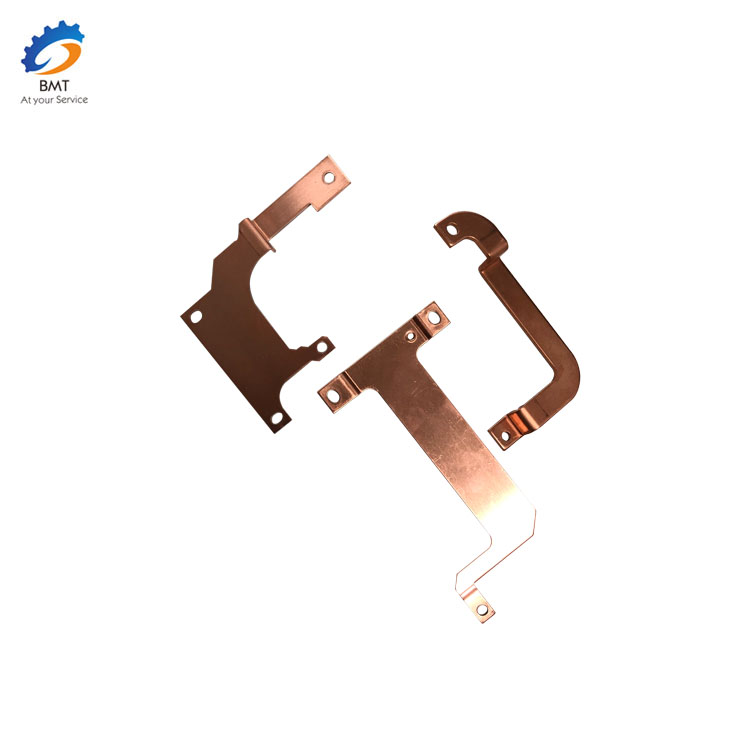

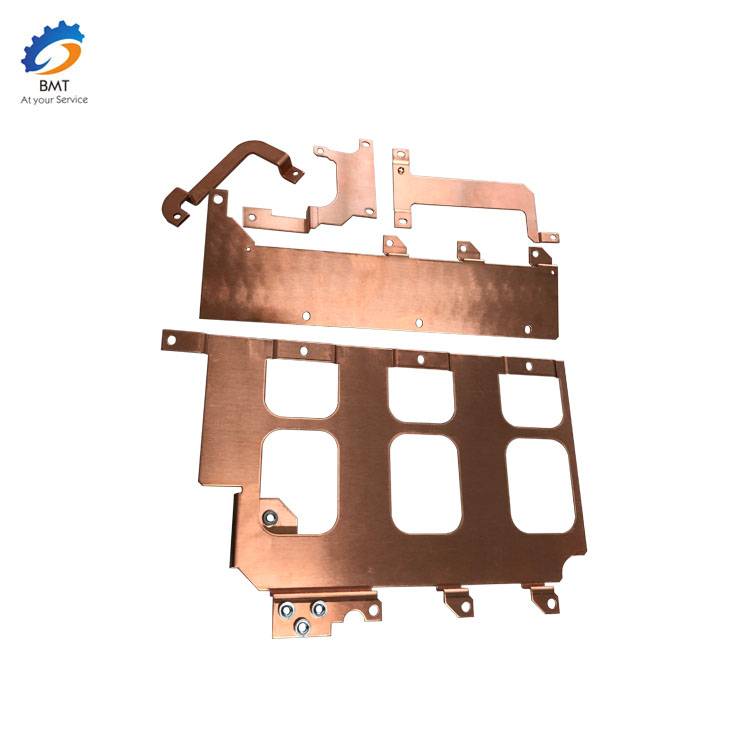

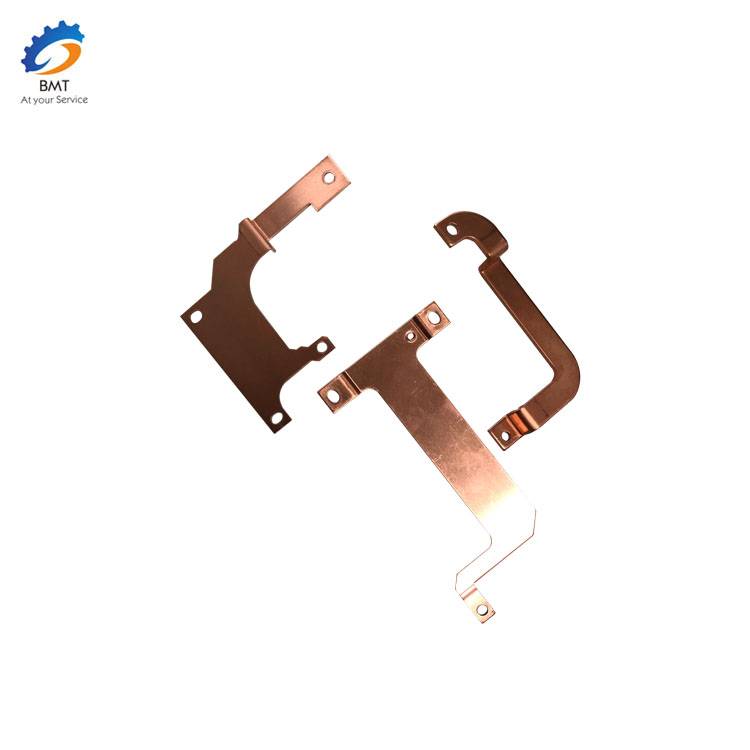

Product Description

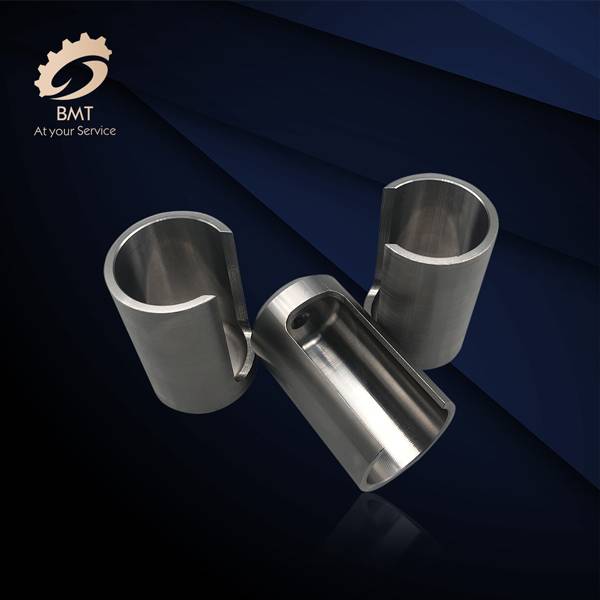

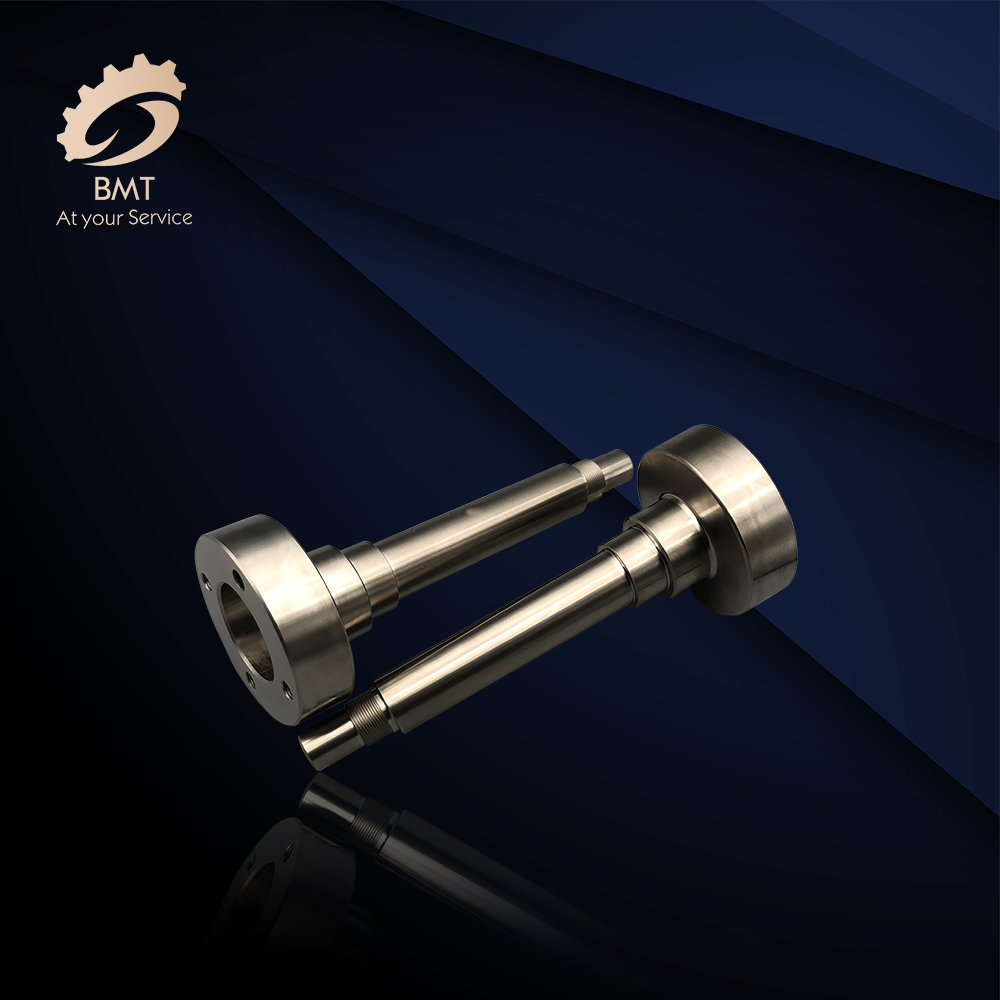

Precision Machining Parts

Precision Machining Parts

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for professional factory for Custom Sheet Metal Enclosures - OEM Sheet Metal Fabrication – Basile, The product will supply to all over the world, such as: Belarus, Rome, Colombia, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Send your message to us:

-

Factory source Cnc Aluminum Parts Machined Serv...

-

Europe style for Outsourcing Cnc Machining - C...

-

High Quality for Precision Metal Fabrication -...

-

Discountable price Sheet Metal Box - Custom Ae...

-

China New Product Precision Turned Components ...

-

2021 New Style Cnc Lathe Machining - CNC Machi...