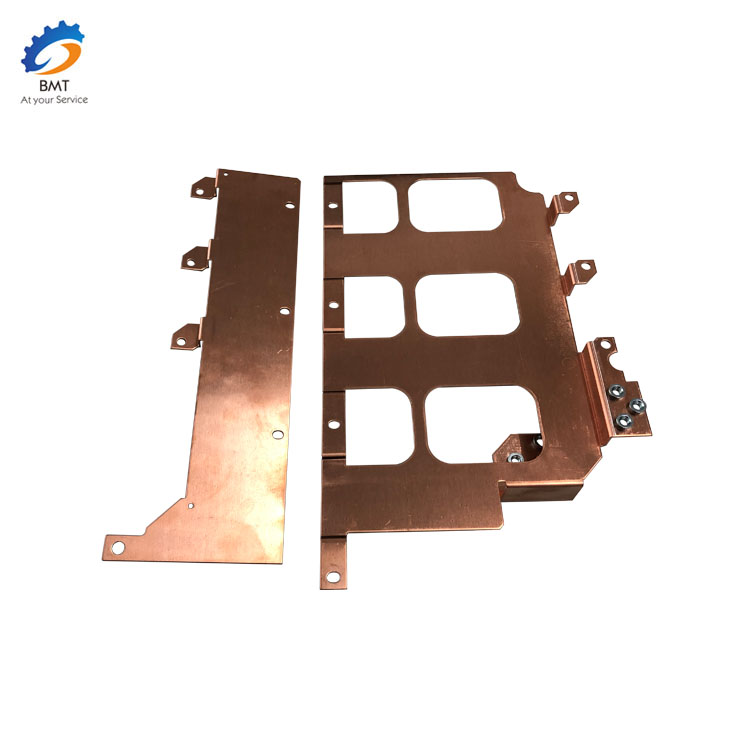

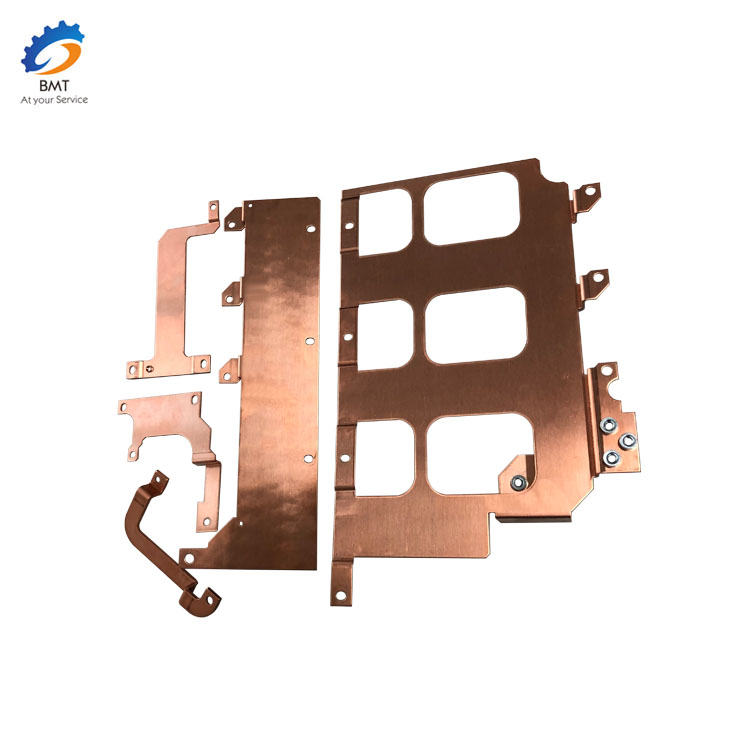

Reasonable price for Cnc Cutting Metal Sheet - OEM Sheet Metal Fabrication – Basile Detail:

Categories of Sheet Metal Fabrication

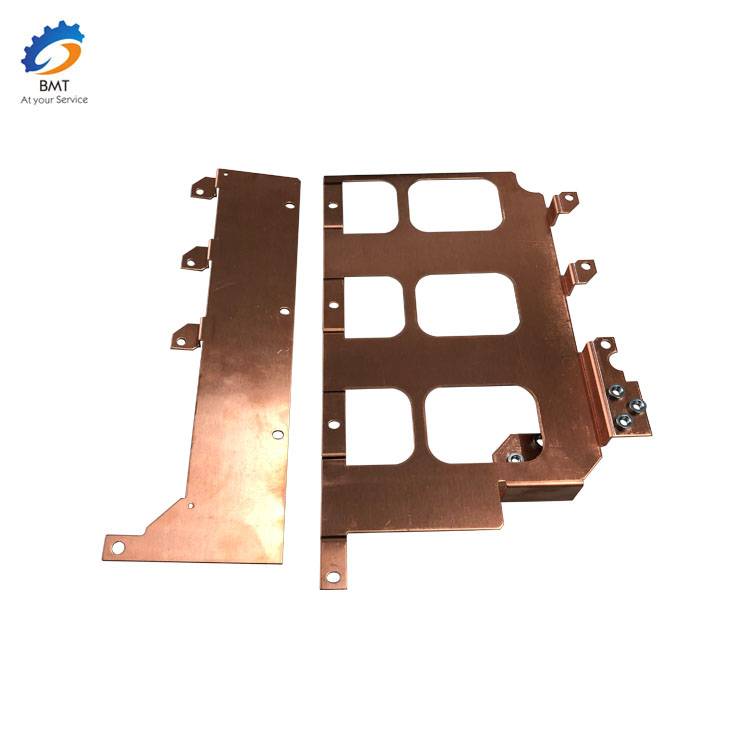

Custom Sheet Metal Fabrication in BMT refers to the manufacturing progress of forming a single or mass production metal sheet parts with custom shapes. Under this progress, it includes many manufacturing ways such as cutting, stamping, punching, bending, press forming, welding, rolling, braking, assembling, galvanizing, powder coating, painting, riveting, etc.

Custom Sheet Metal Fabrication in BMT refers to the manufacturing progress of forming a single or mass production metal sheet parts with custom shapes. Under this progress, it includes many manufacturing ways such as cutting, stamping, punching, bending, press forming, welding, rolling, braking, assembling, galvanizing, powder coating, painting, riveting, etc.

What Are The Advantages Of Custom Metal Fabrication?

In the first place, custom sheet metal fabrication parts are highly durable. With good properties of high structural strength and longevity, it is good for both prototyping and end-use.

In the second place, the custom parts can be built from a full range of Sheet metal materials, and offer a broad range of mechanical properties.

In the third place, production is cost-efficient. With the high efficiency of replicating ability, the metal fabrication machines can produce parts at a low cost per unit. Meanwhile, due to the high efficiency of manufacturing way, parts can be built and delivered at a rapid turnaround.

Last but not least, it can be customized into different sizes with all kinds of finishes.

Three industries’ categories involves in most sheet metal fabrication: Commercial, Industrial and Structural.

Commercial Fabrication refers to sheet metal fabrication done while creating commercial products. This category covers goods designed for use by consumers. Appliances, electronics, and cars, etc. are all common consumer products produced through commercial fabrication.

Industrial Fabrication refers to sheet metal fabrication done while creating other mechanical equipment. Manufacturers are the main consumers of most products produced through industrial sheet metal fabrication. For example, tools like bandsaws, hydraulics, and drill presses are produced through industrial fabrication.

Structural Fabrication refers to metalworking done while building process. It is the process of bending, cutting, and assembling structural steel to create parts, machines, or structures. Structural steel fabricators use machinery to construct a steel piece viable for structural assembly. Large-scale sheet metal fabrication projects create the metal components used by shops, manufacturers, buildings, and skyscrapers. Under normal conditions, metal siding, structural framing studs, roofing, and load bearing fall into this category.

With so many industries reliant on sheet metal fabrication, it is easy to see why there is such a large consumer base for fabricated sheet metal products. If you need more help finding a sheet metal fabricator for your custom project, we are here to help.

We are waiting to assist you with whatever your manufacturing needs may be. Contact us today for your needs.

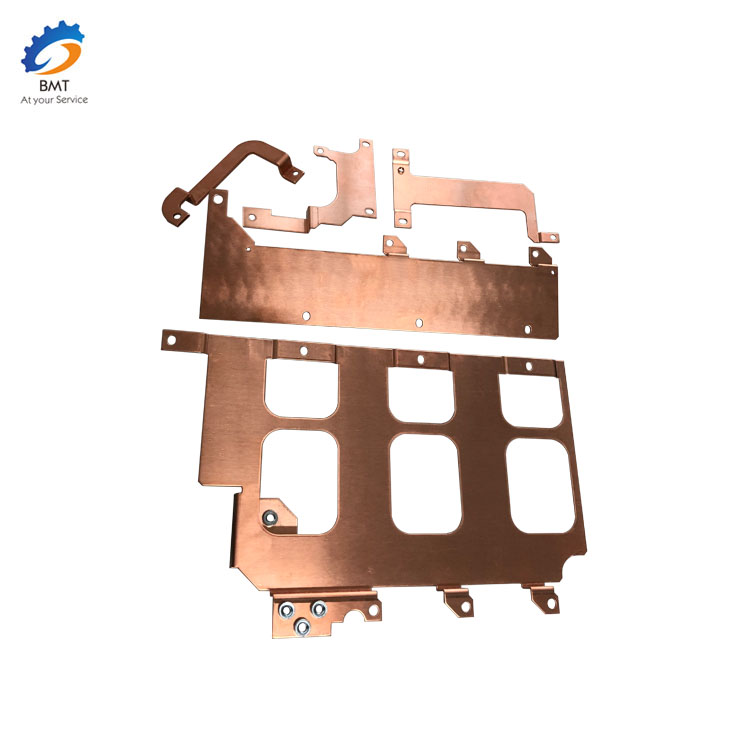

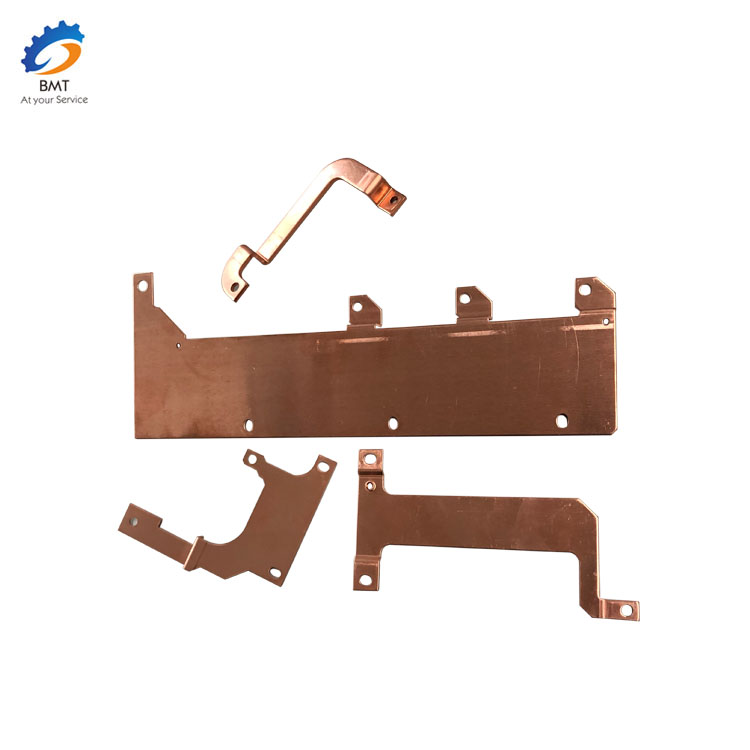

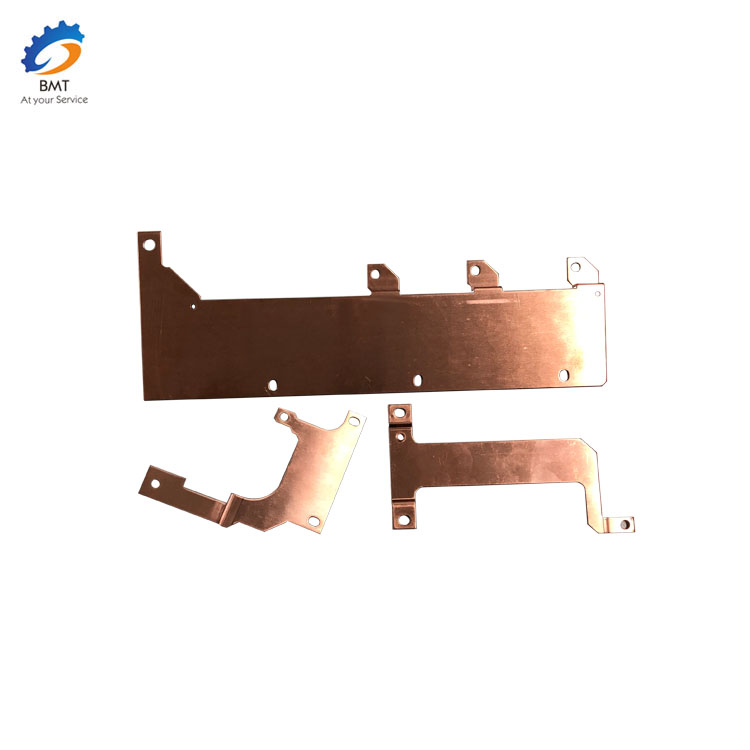

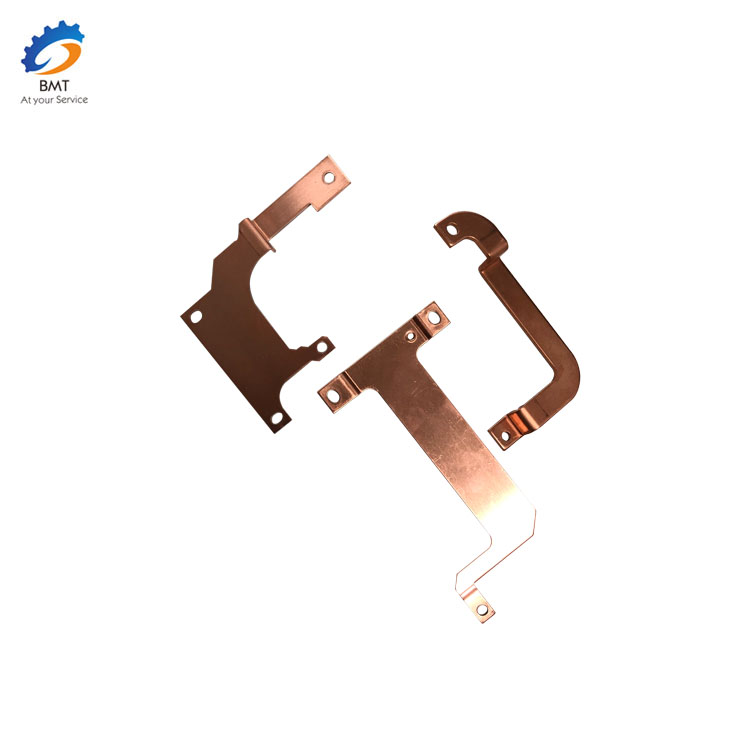

Product Description

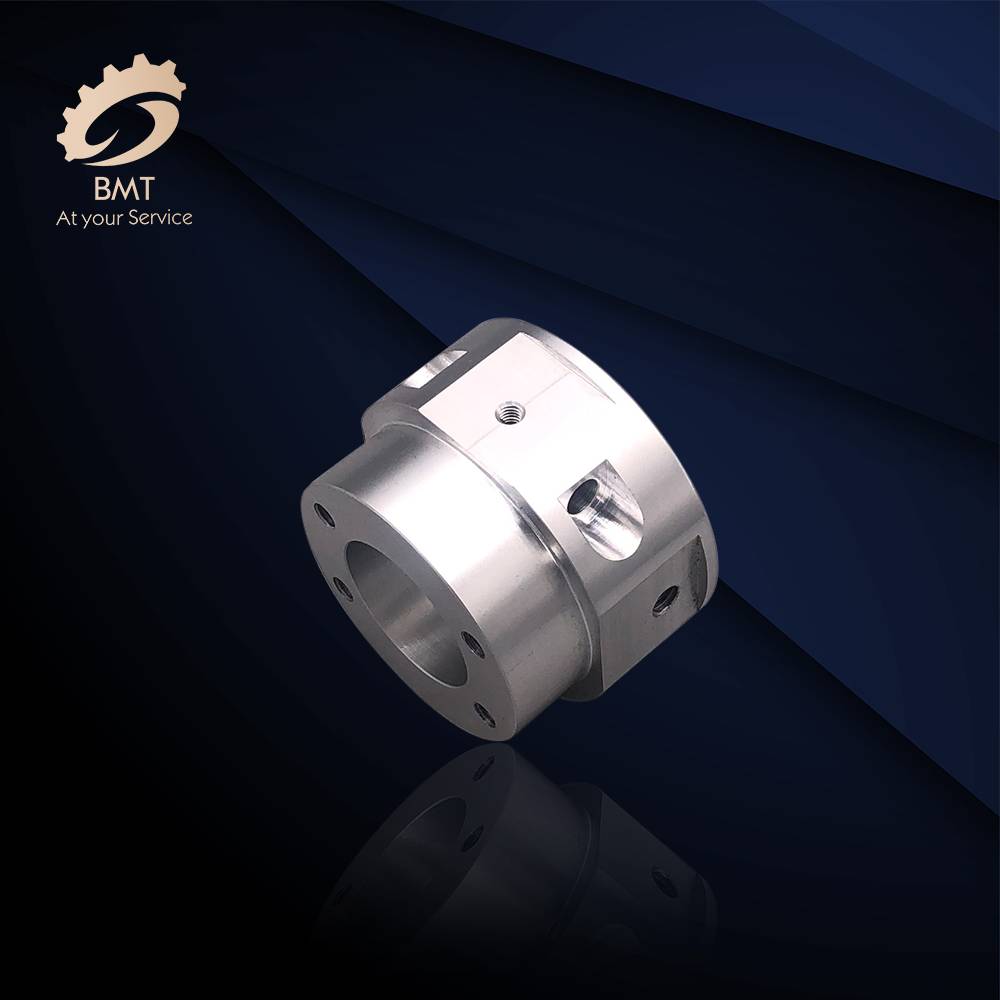

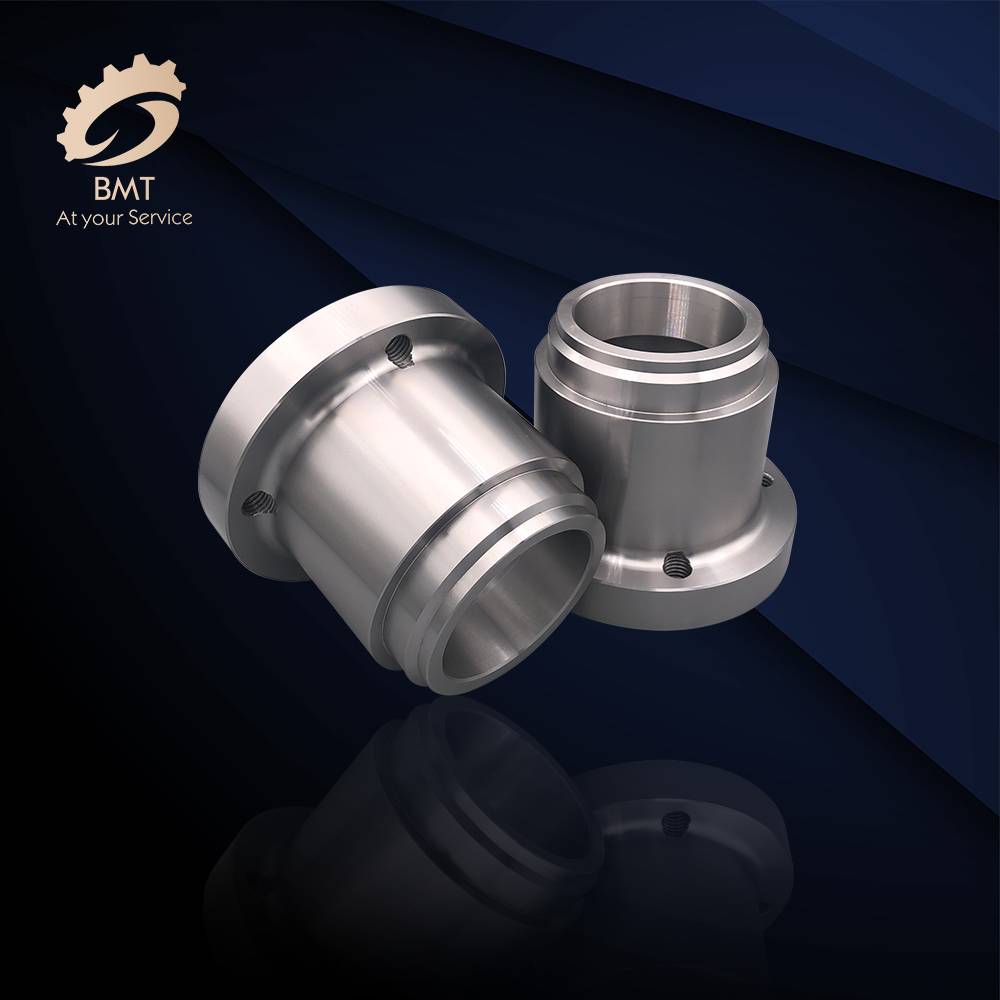

Precision Machining Parts

Precision Machining Parts

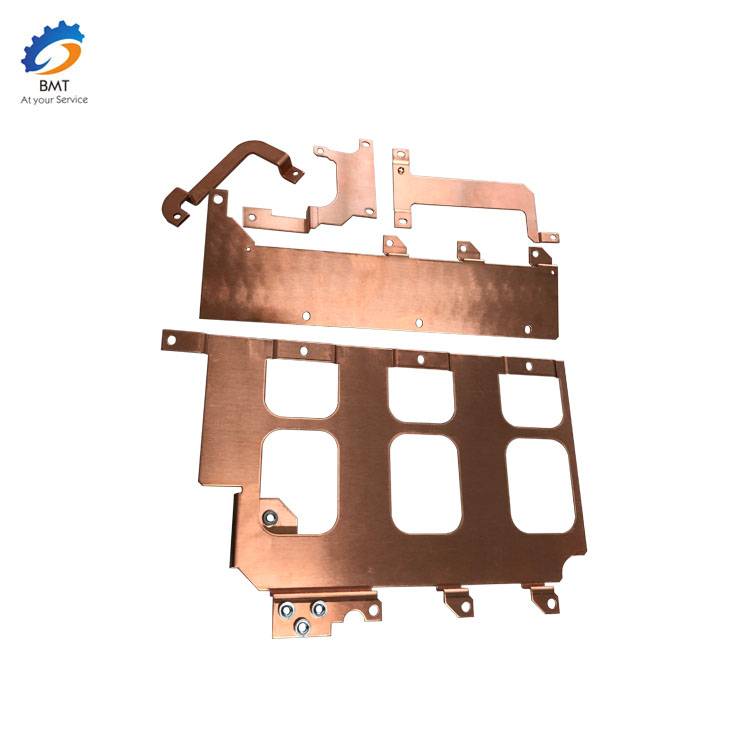

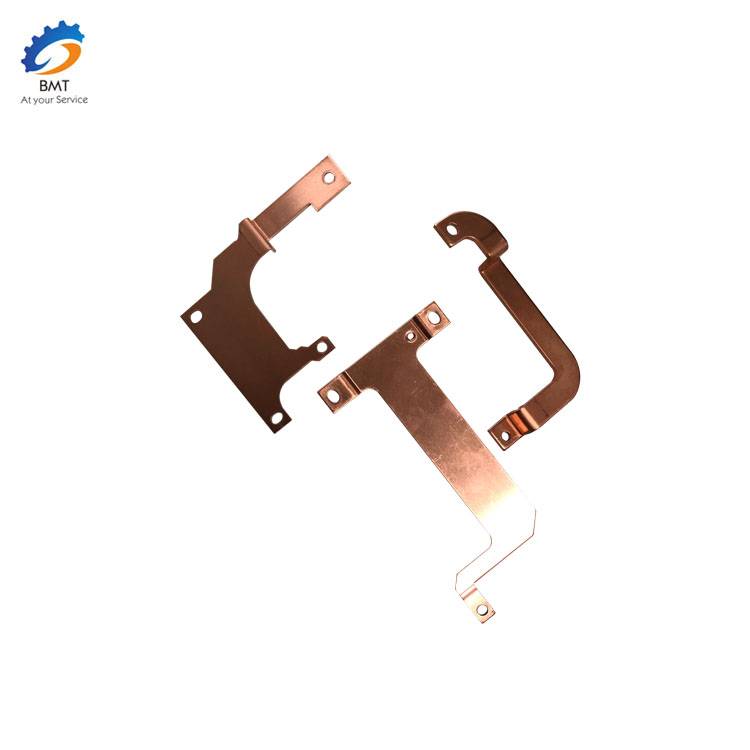

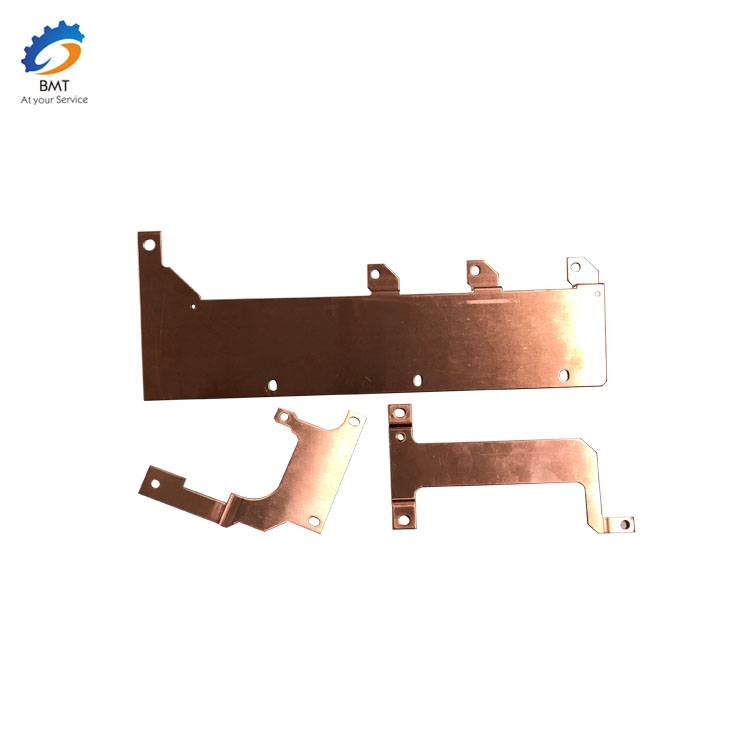

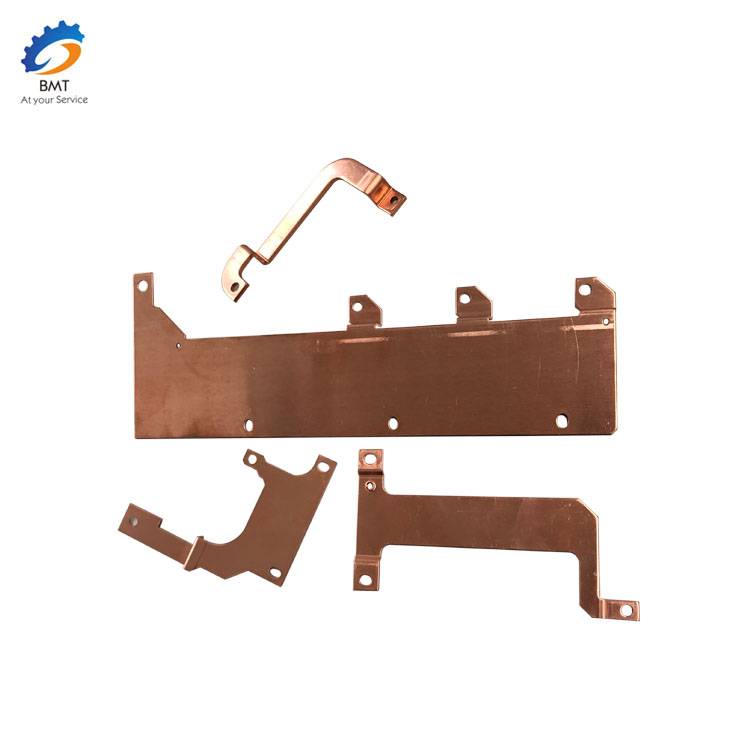

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for Reasonable price for Cnc Cutting Metal Sheet - OEM Sheet Metal Fabrication – Basile, The product will supply to all over the world, such as: kazan, Sri Lanka, Morocco, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.