Super Lowest Price Precision Cnc Engineering - Features of Milling Cutters – Basile Detail:

Features of Milling Cutters

When dealing with difficult-to-machine materials such as Hastelloy, waspaloy, Inconel and Kovar, machining knowledge and experience is very important. At present, there are more and more applications of nickel-based alloys, mainly used to manufacture some important parts in aerospace, medical and chemical industries. These materials have high strength, corrosion resistance, and can withstand extremely high temperatures. Some special elements are added to the above materials to obtain superior performance. On the other hand, however, these materials also become particularly difficult to mill.

We know that nickel and chromium are the two main additives in nickel-based alloys. Adding nickel can increase the toughness of the material, adding chromium can improve the hardness of the material, and the balance of other components can be used to predict the wear of the tool. Other elements added to the material may include: silicon, manganese, molybdenum, tantalum, tungsten, etc. It is worth noting that tantalum and tungsten are also the main components used to make cemented carbide, which can effectively improve the performance of cemented carbide , but the addition of these elements to the workpiece material makes it difficult to mill, almost like cutting one carbide tool with another.

Why do milling cutters cutting other materials break faster when milling nickel-based alloys? It is important to understand this. Machining nickel-based alloys, the tool cost is high, and the cost is 5 to 10 times that of milling general steel.

Needless to say, heat is the most important factor affecting tool life when milling nickel-based alloys, because even the best carbide tools can be destroyed by excessive cutting heat. The generation of extremely high cutting heat is not just a problem for milling nickel alloys. So when milling these alloys, heat needs to be controlled. In addition, it is very important to know the heat value generated when machining with various types of tools (high-speed steel tools, carbide tools or ceramic tools).

Many tool damage is also related to other factors, and substandard fixtures and tool holders can shorten tool life. When the rigidity of the clamped workpiece is insufficient and movement occurs during cutting, it may cause the fracture of the cemented carbide matrix. Sometimes small cracks develop along the cutting edge, and sometimes a piece breaks off the carbide insert, making it impossible to continue cutting. Of course, this chipping can also be caused by too hard carbide or too much cutting load. At this time, high-speed steel tools should be considered for processing to reduce the occurrence of chipping. Of course, high-speed steel tools cannot withstand higher heat like cemented carbide. Exactly what material to use must be determined on a case-by-case basis.

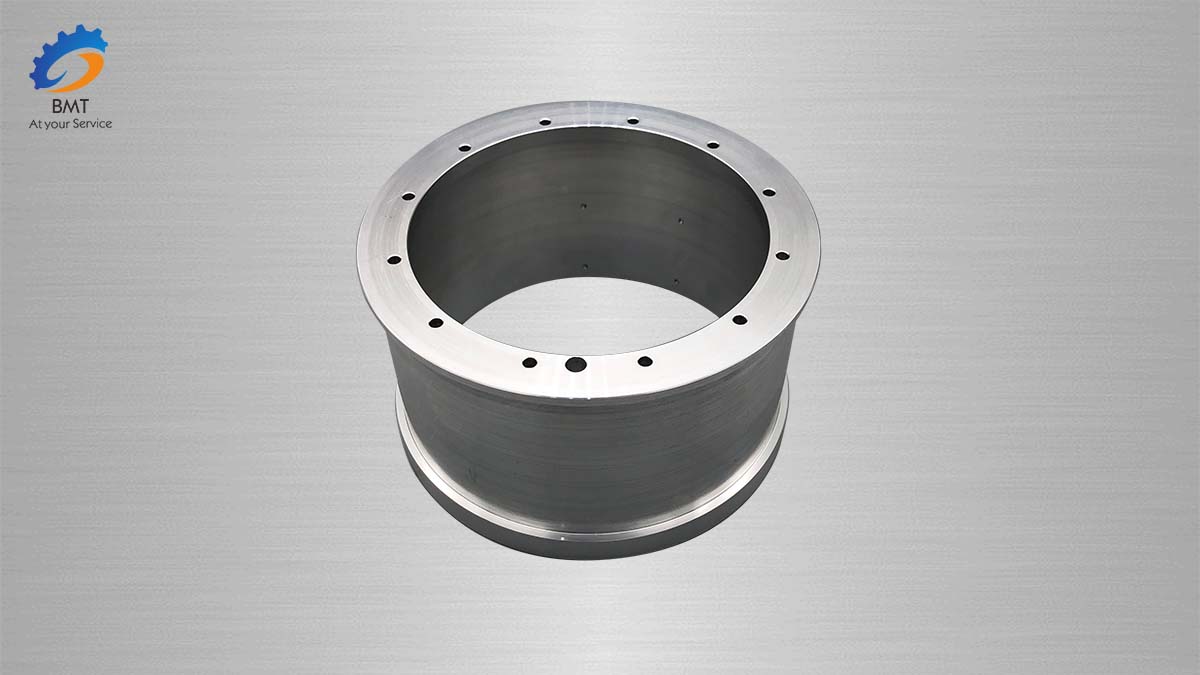

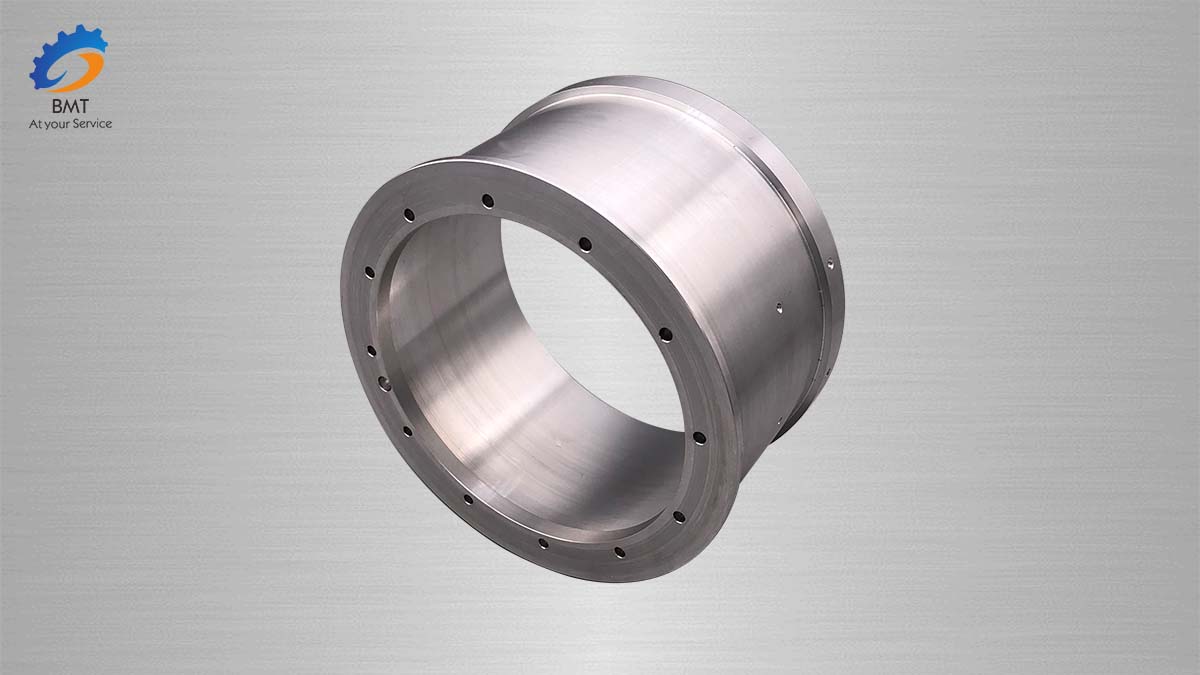

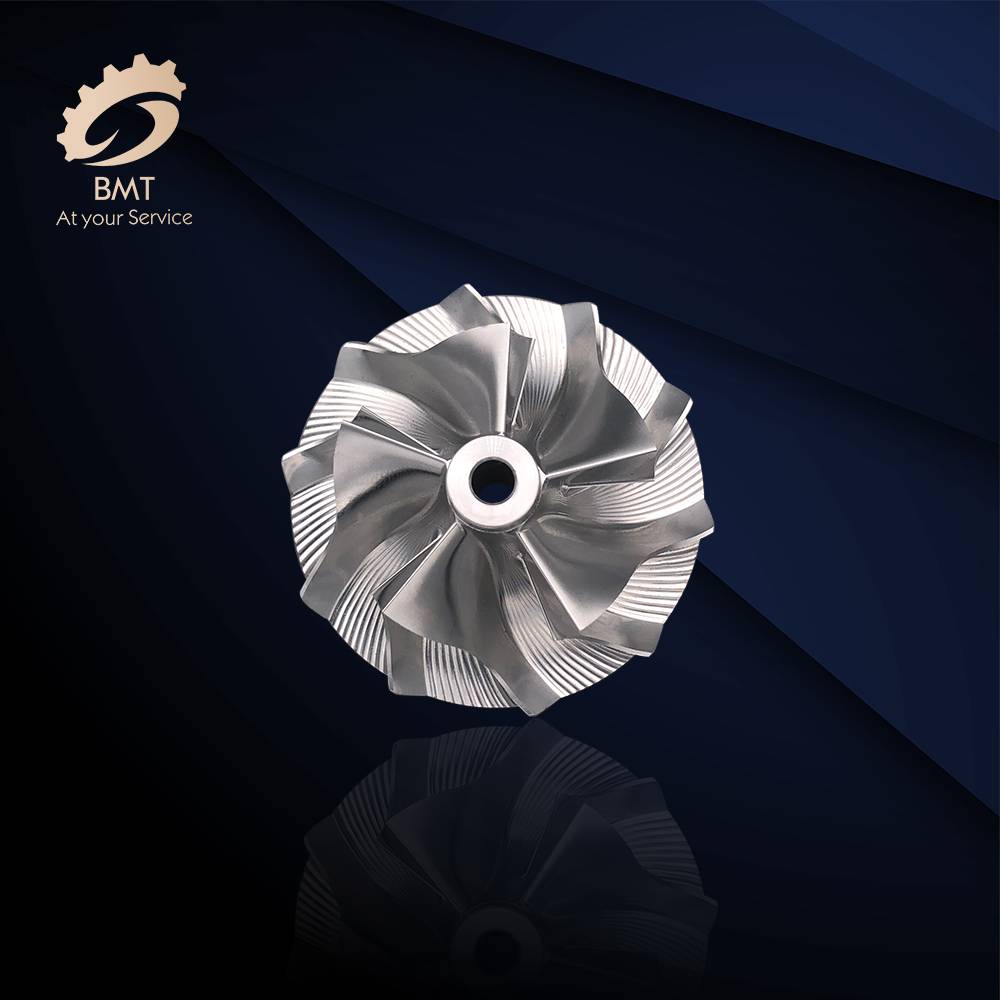

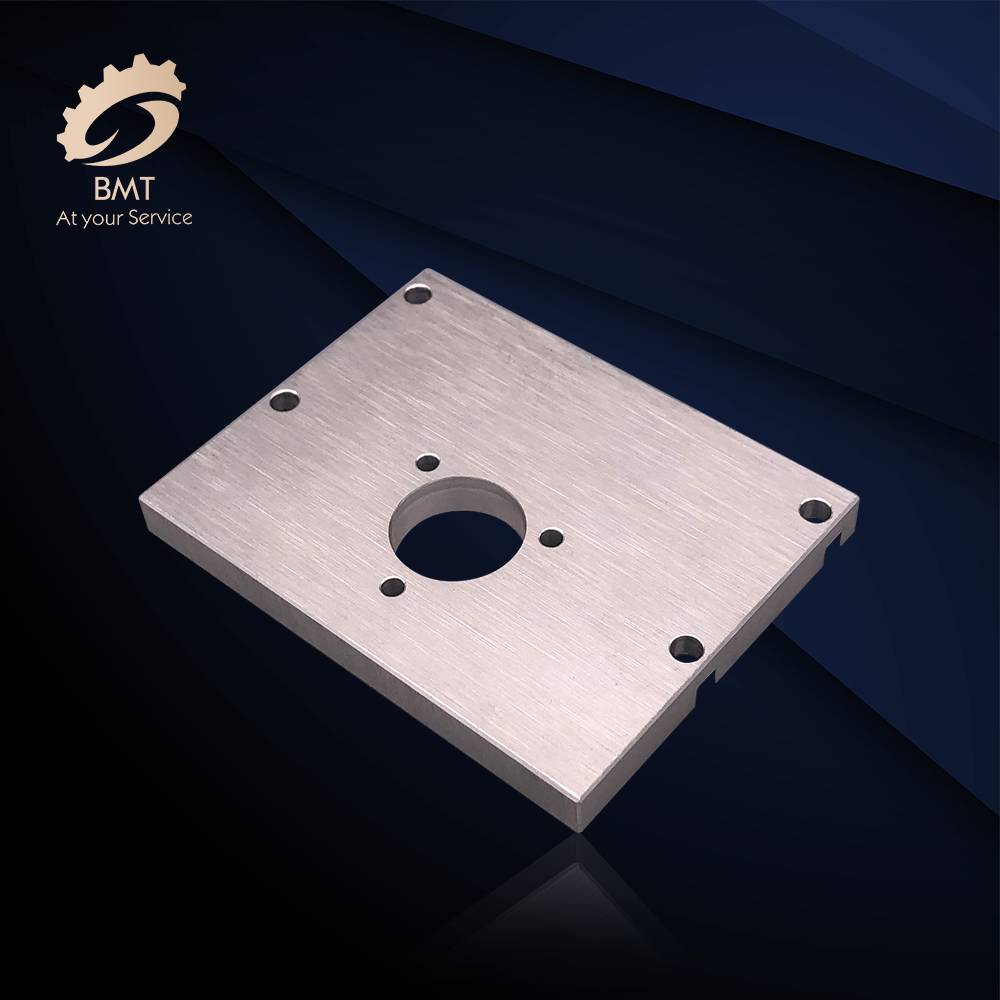

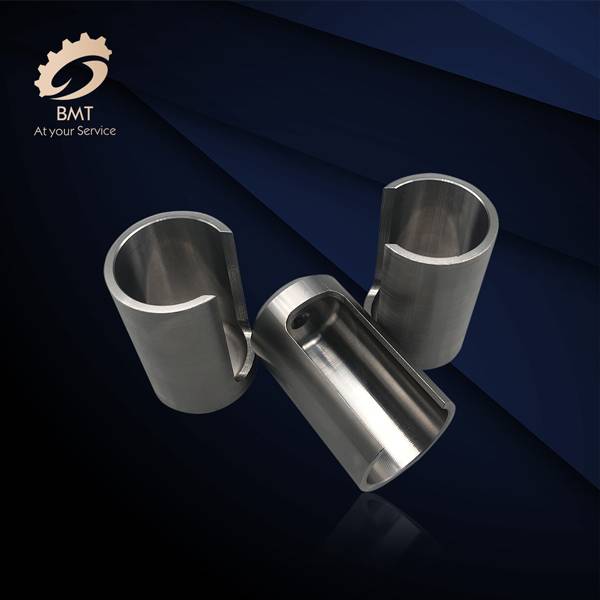

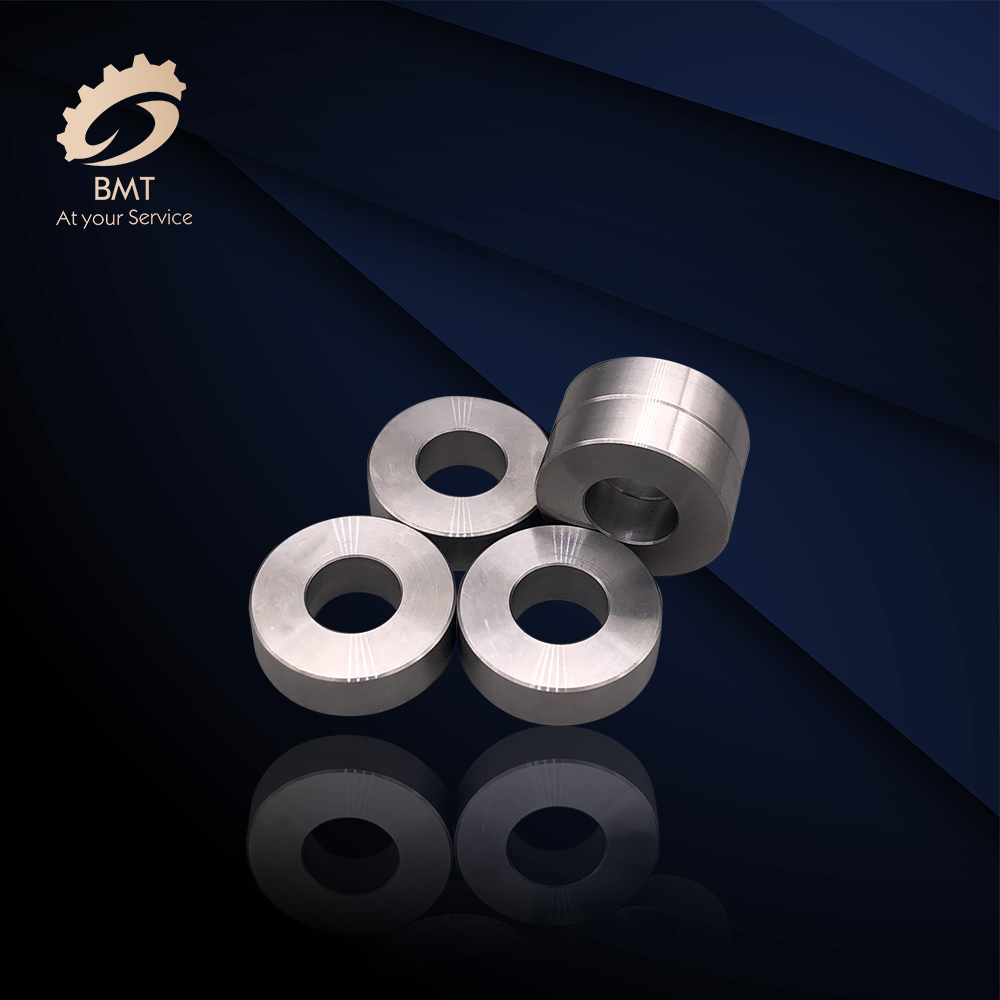

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Super Lowest Price Precision Cnc Engineering - Features of Milling Cutters – Basile, The product will supply to all over the world, such as: Georgia, Thailand, Swiss, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

Send your message to us:

-

PriceList for 5 Axis Cnc Service - Axis High P...

-

Best quality Plastic Cnc Services - Factors th...

-

Hot sale Factory Cnc Build Parts - Professiona...

-

New Delivery for Cnc Precision Parts - High Pr...

-

Wholesale Dealers of Carbon Steel Precision Cnc...

-

Popular Design for Sheet Metal Mesh - OEM Shee...