Titanium Alloy Mechanical Properties

Titanium alloy has the advantages of light weight, high specific strength, good corrosion resistance, so it is widely used in the automotive industry, the application of titanium alloy is the most automotive engine system. There are many advantages to making engine parts out of titanium alloy. The low density of titanium alloy can reduce the inertial mass of moving parts, and titanium valve spring can increase the free vibration, reduce the vibration of the body, improve the engine speed and output power.

Reduce the inertial mass of moving parts, so as to reduce the friction force and improve the fuel efficiency of the engine. Choosing titanium alloy can reduce the load stress of related parts, reduce the size of parts, so as to reduce the mass of the engine and the whole vehicle. The reduction of inertial mass of components reduces vibration and noise and improves engine performance.

The application of titanium alloy in other parts can improve the comfort of personnel and the beauty of cars. In the application of automobile industry, titanium alloy has played an inestimable role in energy saving and consumption reduction. Despite these superior properties, titanium parts and alloys are still far from being widely used in the automotive industry due to problems such as high price, poor formability and poor welding performance.

With the development of near-net forming technology of titanium alloy and modern welding technology such as electron beam welding, plasma arc welding and laser welding in recent years, the forming and welding problems of titanium alloy are no longer the key factors restricting the application of titanium alloy. The most important reason hinding the universal application of titanium alloy in the automobile industry is the high cost.

The price of titanium alloy is much higher than that of other metals, both in the initial smelting and subsequent processing of the metal. The cost of titanium parts acceptable to the automotive industry is $8 to $13 /kg for connecting rods, $13 to $20 /kg for valves, and less than $8 /kg for springs, engine exhaust systems and fasteners. At present, the cost of parts produced with titanium is much higher than these prices. The production cost of titanium sheet is mostly higher than $33 /kg, which is 6 to 15 times that of aluminum sheet and 45 to 83 times that of steel sheet.

Send your message to us:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

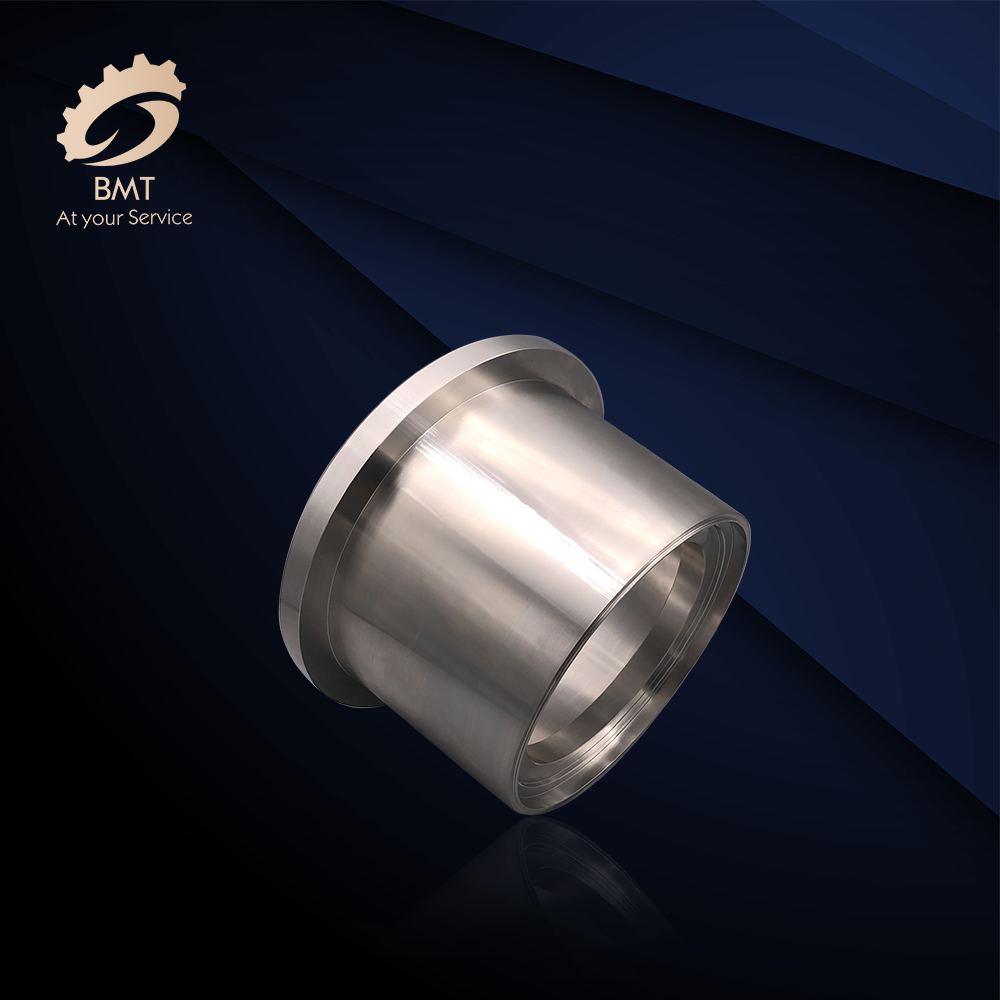

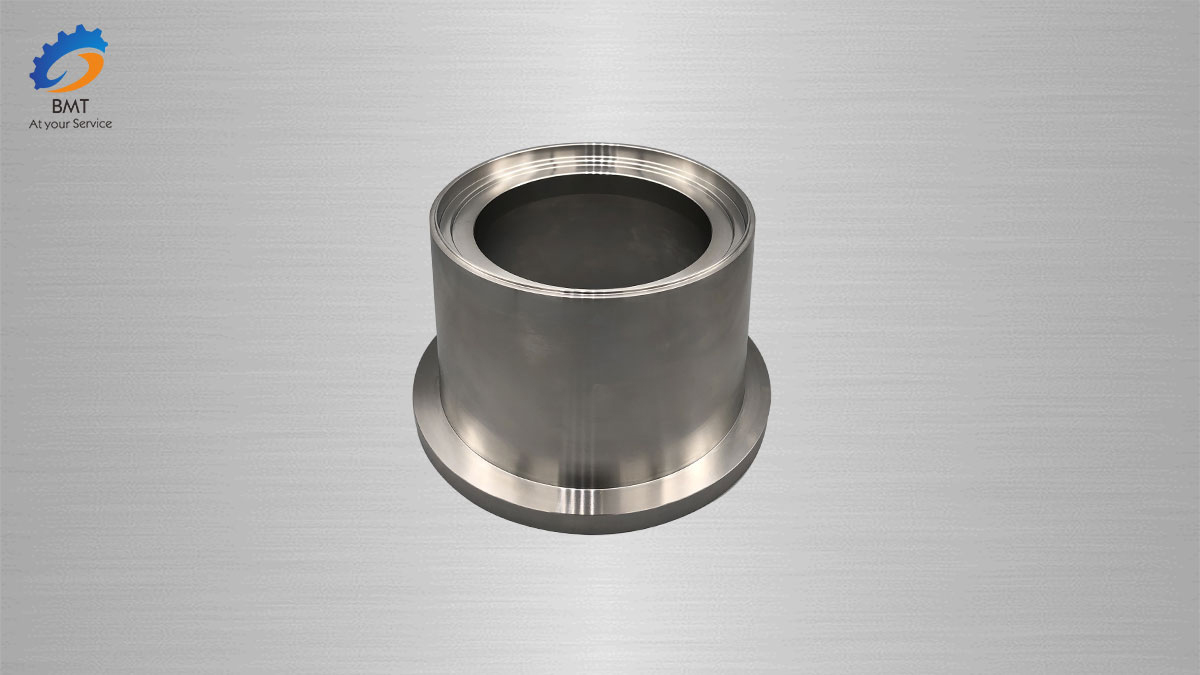

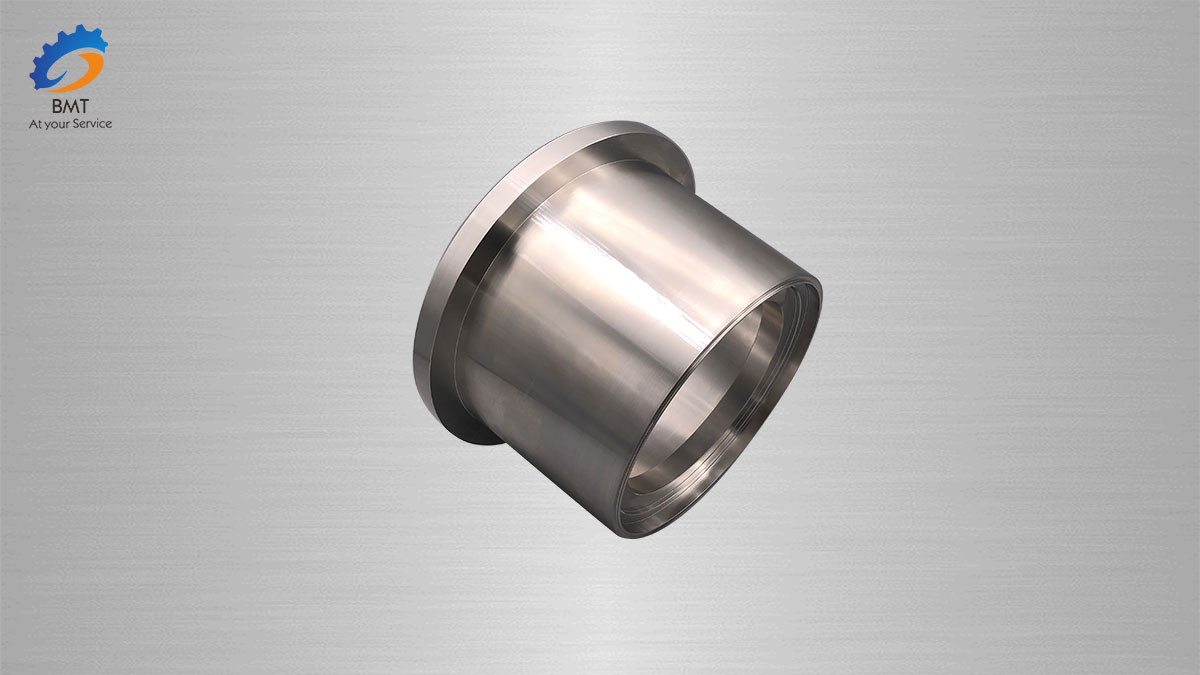

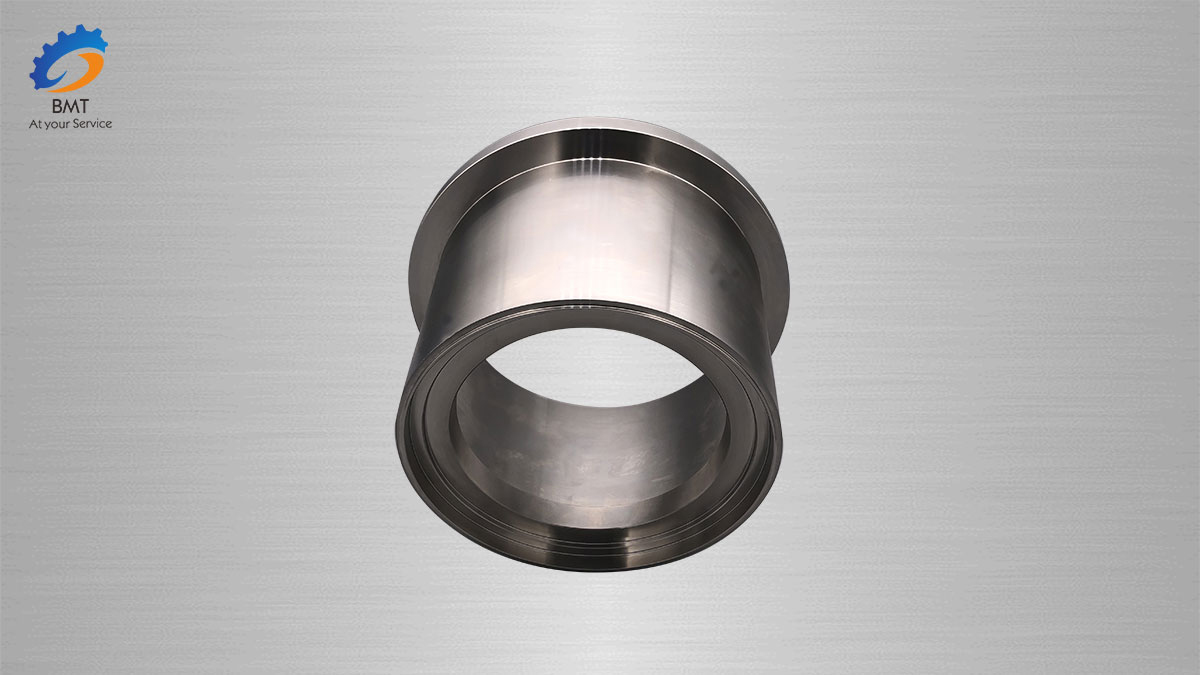

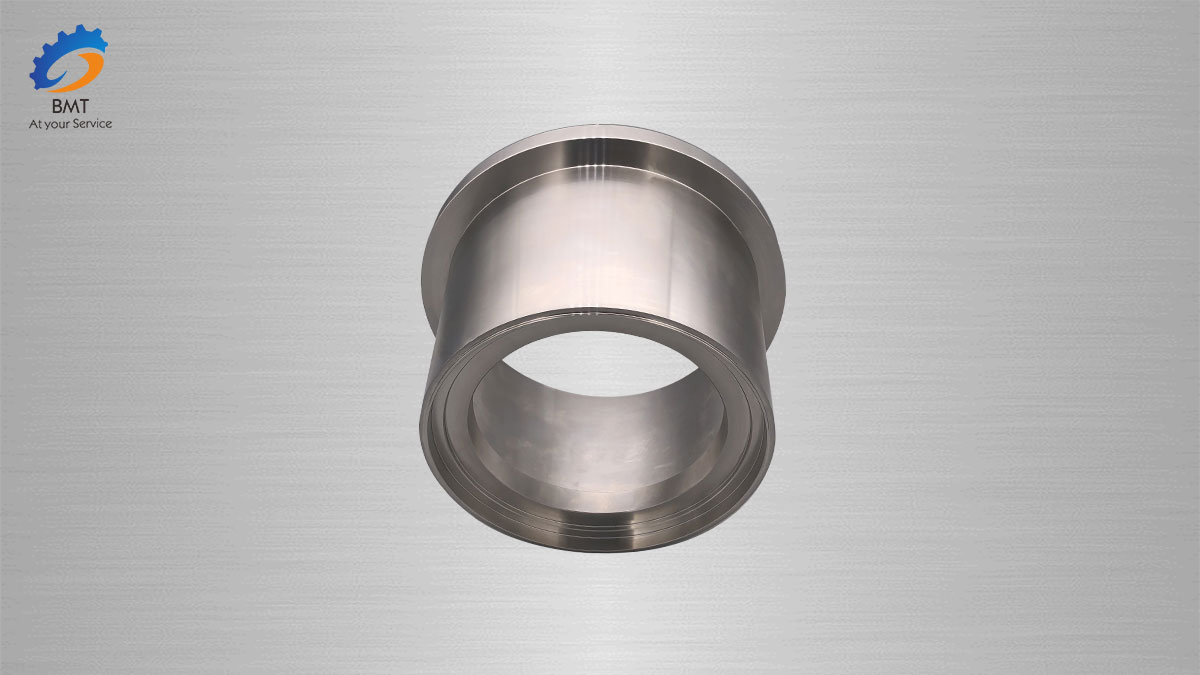

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes