Titanium Seamless Pipes and Tubes

Gr1, Gr 2, Gr 3 are all industrial pure titanium. They have high mechanical properties, excellent stamping performance, and can be welded in various forms. The strength of the welded joint can reach 90% of the strength of the base metal, and the cutting performance is good. Titanium tube has high corrosion resistance to chloride, sulfide and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloys, stainless steel, and nickel-based alloys. Titanium is also resistant to water impact.

Titanium alloy is mainly used for the production of aircraft engine compressor components, followed by the structural parts of rockets, missiles and high-speed aircraft. In the mid-1960s, titanium and its alloys have been used in general industry to make electrodes in the electrolysis industry, condensers in power stations, heaters for petroleum refining and seawater desalination, and environmental pollution control devices. Titanium and its alloys have become a kind of corrosion-resistant structural materials. In addition, it is also used in the production of hydrogen storage materials and shape memory alloys.

Compared with other metal materials, titanium alloy has the following advantages:

- High specific strength (tensile strength/density), tensile strength can reach 100~140kgf/mm2, and the density is only 60% of steel.

- Medium temperature has good strength, the use temperature is several hundred degrees higher than that of aluminum alloy, it can still maintain the required strength at medium temperature, and can work for a long time at a temperature of 450~500℃.

- Good corrosion resistance. A uniform and dense oxide film is immediately formed on the surface of titanium in the atmosphere, which has the ability to resist corrosion by various media. Generally, titanium has good corrosion resistance in oxidizing and neutral media, and has better corrosion resistance in seawater, wet chlorine and chloride solutions. But in reducing media, such as hydrochloric acid and other solutions, the corrosion resistance of titanium is poor.

- Titanium alloys with good low temperature performance and extremely low interstitial elements, such as Gr7, can maintain a certain degree of plasticity at -253℃.

- The modulus of elasticity is low, the thermal conductivity is small, and it is non-ferromagnetic.

BMT is specialized in exporting seamless titanium pipes and tubes, and owning an annual production of 5,000 tons. BMT seamless pipes and tubes feature high specific strength, corrosion resistance, good cryogenic property, low elasticity modulus, low thermal conductivity and no ferromagnetism.

BMT range of seamless titanium pipe and tube sells broadly around the world. Righd supervision is executed in terms of quality, including chemial component analysis, air pressure testing, nondestructive testing, eddy current testing and ultrasonic testing. We also have mechanical tesing, covering tensile test, flaring test, flattening test, ferroxyl test, RT, X-Ray test, etc.

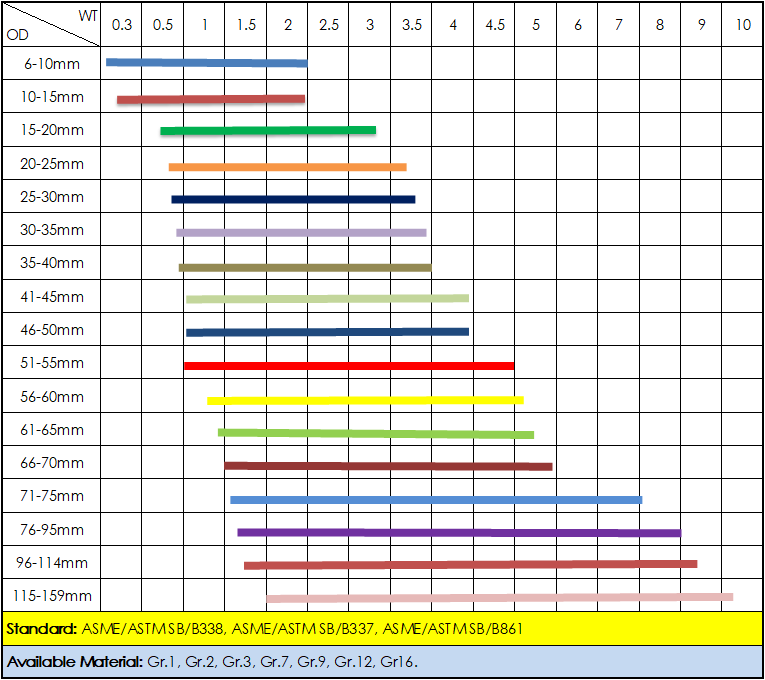

Titanium Seamless Pipes and Tubes Size Range:

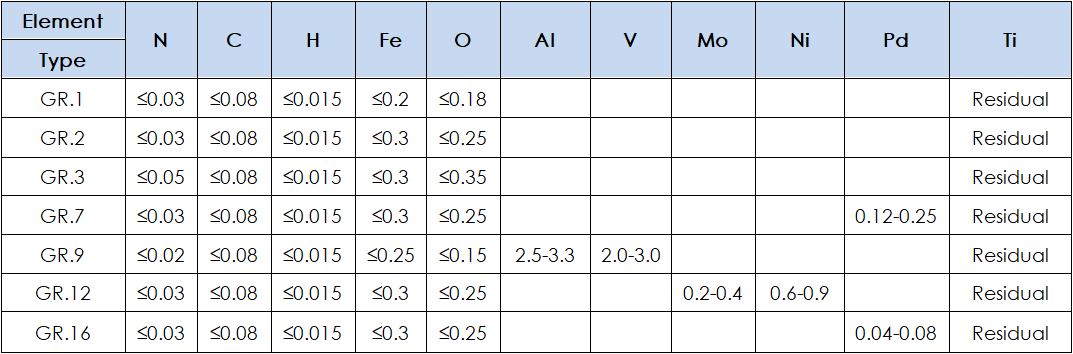

Available Material Chemical Composition:

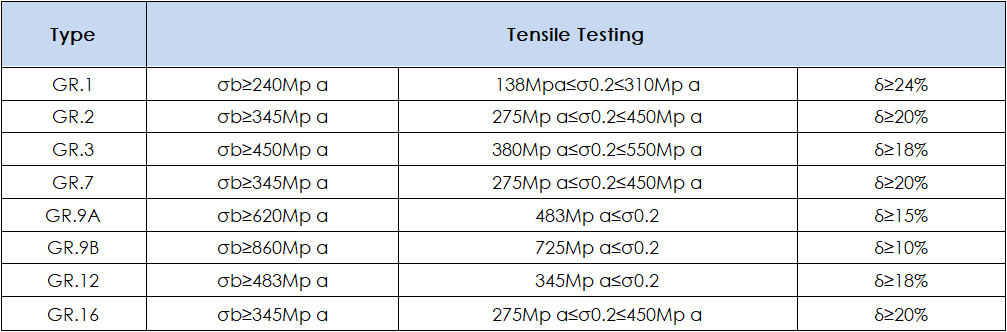

Available Material Mechanical Property:

Inspection test:

- Chemical Composition Analysis

- Mechanical Property Test

- Tensile Testing

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Air pressure test under water)

- NDT Test

- Eddy-Current Test

- Ultrasonic Test

- LDP Test

- Ferroxyl Test

Productivity (Max and Min amount of Order): Unlimited, according to order.

Lead Time: The general lead time is 30 days. However, it depends on the amount of the order accrdingly.

Transportation: The general way of transportation is by Sea, by Air, by Express, by Train, which shall be selected by customers.

Packing:

- Pipe ends to be protected with plastic or cardboard caps.

- All fittings to be packed to protect ends and facing.

- All other goods will be packed by foam pads and related plastic packing and plywood cases.

- Any wood used for packing must be suitable to prevent contamination by contact with handling equipment.